The way technological advancement is reshaping the industries' design, innovation, and manufacturing, were reverse engineering has emerged as one of the most powerful tools driving industrial modernization with shrinking product lifecycles, growing demand for customization, and increasing pressure to deliver high-quality products, businesses across the globe.

A niche engineering practice has now evolved into an essential process for product development, 3D CAD modeling, motion analysis, stack-up analysis, design optimization, and innovation-driven redesign. As industries embrace 3D digitalization and reverse engineering, 3D scanning is playing a central role in bridging the gap between physical and digital worlds.

Let’s explore what reverse engineering is, its growing relevance in modern supply chains and how it is transforming various industrial sectors.

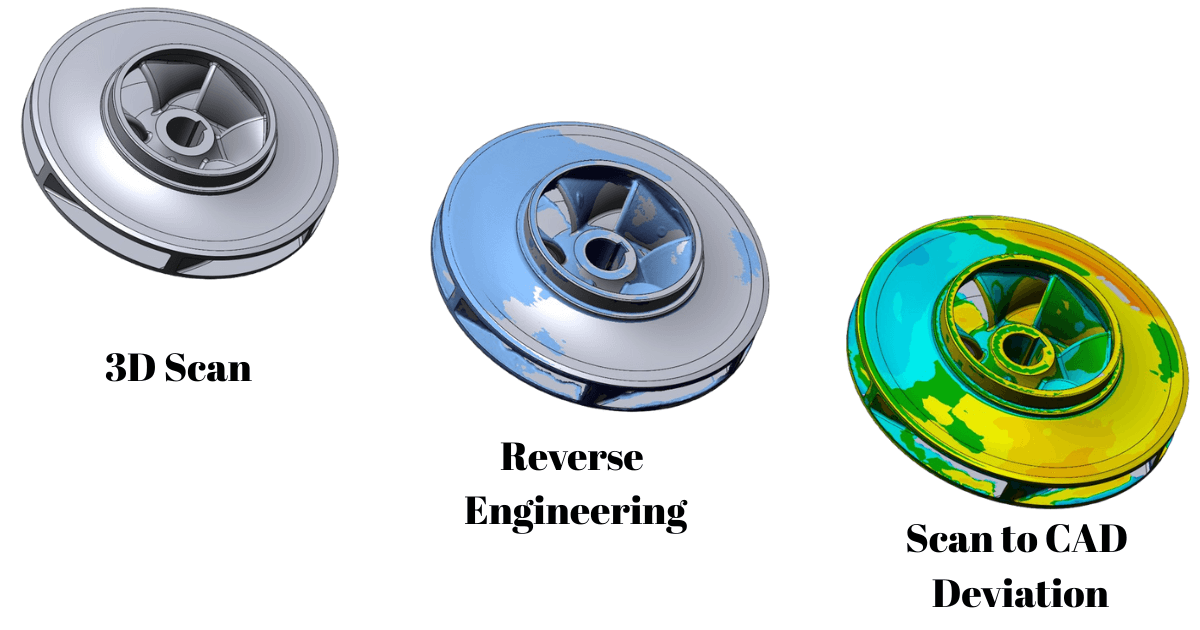

Reverse engineering is the process of capturing the physical geometry, features, and functional characteristics of an existing product to create a detailed 3D digital model. Instead of doing manual measurements, engineers start with using advanced technologies such as 3D laser scanning, profile projectors, CMM measuring mechanisms, point cloud processing, and surface reconstruction with parametric CAD modeling. These tools convert physical objects into highly accurate CAD models that can be used for optimization, redesign, remanufacturing, and quality validation.

At RA Global, we integrate advanced technology with deep engineering expertise to deliver exceptionally precise reverse engineering solutions. Our team converts complex physical components into Class A surface, editable, and manufacturable CAD models with high accuracy. RA Global offers reverse engineering services in Germany, Italy, Norway and Europe with superior accuracy results.

The growing importance of reverse engineering in most advanced and fast-moving technology is driven by challenges such as discontinued parts, long lead times, imported dependencies, and inconsistent quality. Reverse engineering offers an efficient solution by enabling companies to recreate obsolete or unavailable components, reduce dependability on overseas suppliers, improve accuracy in retrofitable part manufacturing, and maintain consistency across production batches. It also helps convert physical components into digital inventories while supporting localized manufacturing and faster turnaround times.

Reverse engineering has become indispensable across multiple industries due to its ability to enhance design accuracy, reduce costs, and revive legacy systems. Key industrial applications include:

Modern reverse engineering is all about precision, flexibility, and usability of the most advanced technologies. One of its standout features is high-accuracy 3D scanning, which can capture even the most intricate shapes, curves, and details of complex parts. Combined with point cloud and mesh processing, raw scan data is cleaned, aligned, and optimized, ready to be converted into 3D CAD design, parametric and surface CAD modeling. This data becomes fully editable CAD designs that can be used for redesign, manufacturing, or DFMEA. Beyond geometry, reverse engineering also provides insights into materials and manufacturing processes, helping engineers understand how a part was originally made. And the best part? These CAD models are fully compatible with CNC machining and 3D printing, making it easy to bring designs back to life in the real world.

Reverse engineering services bring a lot of advantages for modern industries. It allows companies to reproduce parts without original drawings, making it ideal for legacy conversion for lost or outdated documentation. By leveraging 3D scanning and digital modeling, reverse engineering accelerates product development, reduces design cycles, and speeds up prototyping. It also improves design efficiency by quick 3D CAD conversion, optimizing structures, enhancing performance, and minimizing material usage. Furthermore, reverse engineering offers cost-effective manufacturing, as digital rebuilding avoids expensive redesigns from scratch and repeatability of manufacturing to benchmark the product. Quality control is enhanced through precise comparison of scanned geometry with CAD models, ensuring dimensional accuracy. It also helps reduce lead times, enabling rapid part replacement and meeting deadlines for remanufacturing.

Reverse engineering is redefining how industries design, replicate, and optimize products. Whether it’s about replacing obsolete components, improving product performance, DFMEA, or supporting prototyping, reverse engineering has become a cornerstone of modern industrial innovation.

By speeding up the 3D CAD modelling and CAD conversion, reverse engineering empowers industries to unlock new levels of efficiency, accuracy, and competitiveness, making it an essential technology for the future.

© 2026 RA Global Tech Solutions

Site design and developed by Rajkar Global