CT Measuring Services

What are CT measuring services?

CT measuring services, also known as industrial computed tomography measuring, are a nondestructive testing method that uses X-ray technology to create detailed 3D images of the internal and external structures of objects. These services are used for quality control, reverse engineering, metrology, and failure analysis in various industries.

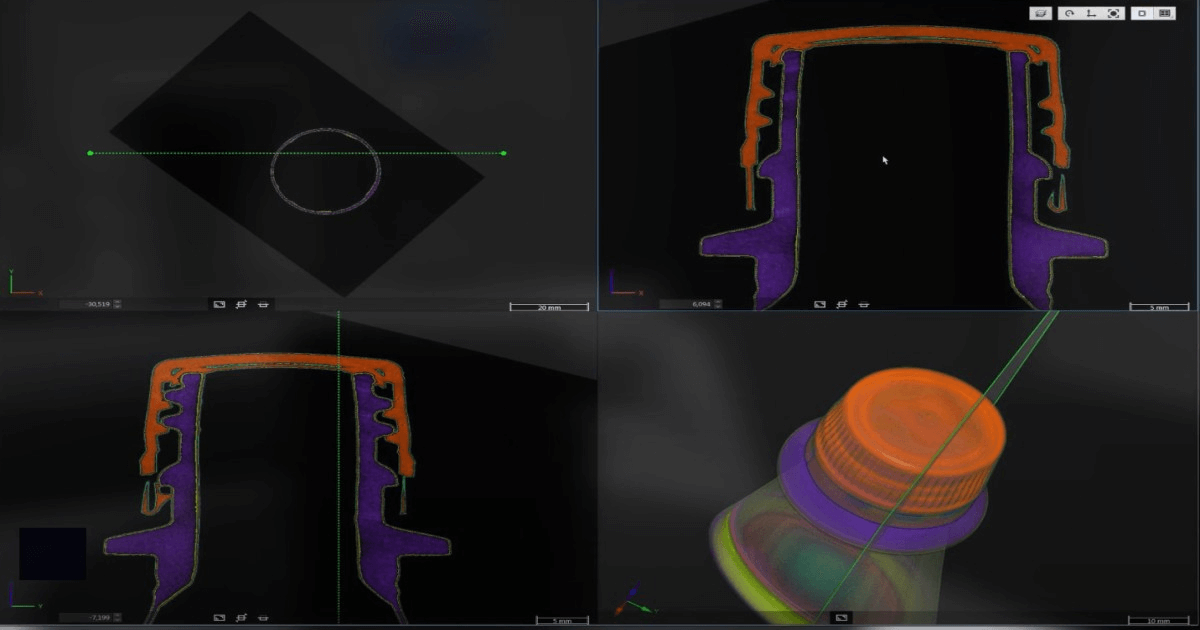

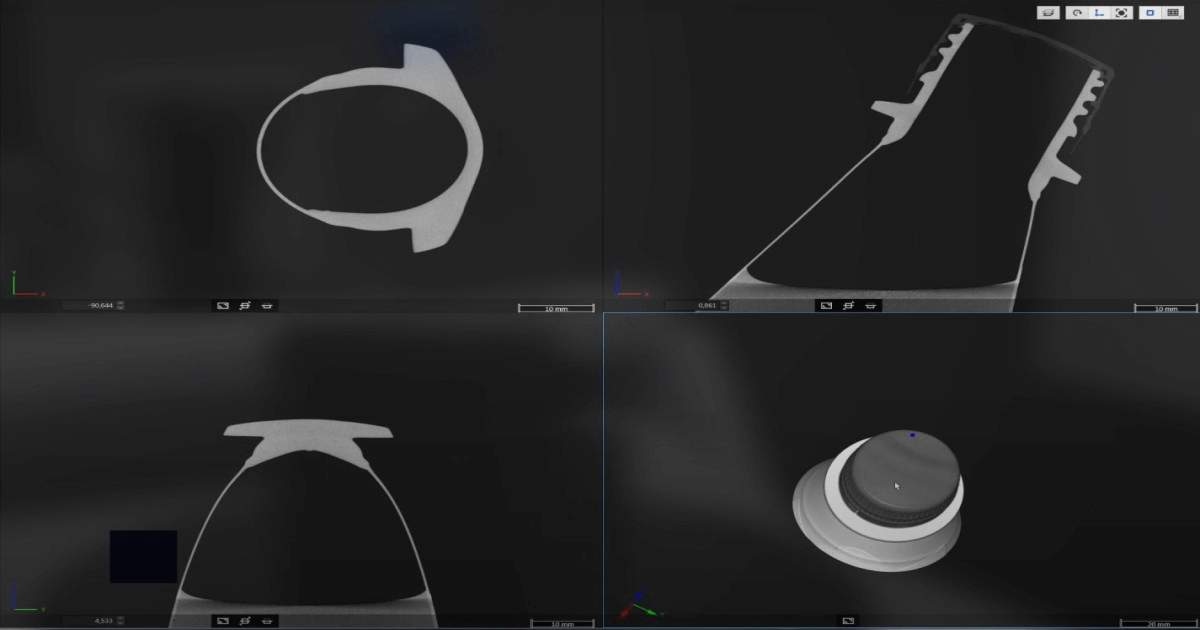

CT measuring, or X-ray computed tomography, is a nondestructive testing method that utilizes advanced X-ray technology to create detailed cross-sectional images of a material or object. These slices are then combined to create a 3D model, which is ideal for precise measurement and analysis. Unlike traditional measuring methods, CT scanning allows for the inspection of internal and external structures without altering or damaging the original sample.

Key Aspects of CT measuring services:

- Non-Destructive Inspection: CT measuring allows complete internal and external analysis of components without damaging or disassembling them, preserving the part for further use.

- High-Precision 3D Measurement: Using advanced X-ray computed tomography, it provides highly accurate dimensional data for complex geometries, including hidden or internal features.

- Volumetric and Structural Analysis: The technology captures internal voids, cracks, porosity, inclusions, and assembly alignment, making it ideal for quality control and failure analysis.

- Multi-Material Compatibility: CT measuring can handle metals, plastics, composites, and multi-material assemblies, offering versatility across industries.

- Digital Data Output and 3D CAD Integration: Generates 3D CAD models, cross-sectional views, and volumetric datasets, enabling reverse engineering, design validation, and simulation-based analysis.

Why are CT measuring services important?

CT measuring services are crucial because they provide accurate, nondestructive inspection of components that traditional measurement methods often cannot access. By capturing both internal and external geometries in a single 3D scan, CT measurement ensures that every aspect of a part, including hidden features, internal voids, or micro-cracks, is analyzed with precision and reliability.

This level of detail is essential for quality control, reverse engineering, and failure analysis, especially in industries like aerospace, automotive, medical devices, and industrial manufacturing, where even minor defects can lead to costly failures or safety risks. Additionally, the digital data generated by CT scanning enables 3D CAD integration, design validation, and process optimization, helping manufacturers reduce errors, improve efficiency, and maintain consistent product quality.

Despite its advanced capabilities, CT measuring services come with certain challenges. Variations in material density or multi-material components can affect X-ray absorption, potentially causing image artifacts or inaccuracies. 3D scanning complex geometries such as thin walls, intricate internal features, or cavities often requires specialized strategies, while larger parts may exceed the 3D scanning chamber, necessitating segmented 3D scans and data stitching. The process also generates large volumes of data, demanding skilled engineers and advanced software for proper reconstruction, analysis, and conversion to 3D CAD models. Additionally, balancing 3D scan resolution with inspection time, maintaining frequent calibration, managing equipment costs, and accurately interpreting results to distinguish real defects from artifacts are all critical factors that require expertise and precision.

Related Services

CT measuring services are often complemented by a range of advanced inspection and engineering solutions to ensure complete quality control and product validation.

- CMM Inspection: Precise dimensional verification of parts for tolerance and accuracy

- 3D Laser Scanning: High-resolution surface data capture for reverse engineering and inspection

- Metrology Services: Comprehensive measurement solutions for complex industrial components

- Reverse Engineering: Converting scanned data into 3D CAD models for redesign, replication, or improvement

How do CT scan measuring services work?

- Scanning and Image Acquisition: A high-energy X-ray source is selected based on material type, thickness, and density. Optimized scan parameters ensure sufficient contrast and minimal artifacts to support dimensional accuracy.

- Object Rotation: The component is rotated on a precision turntable while the X-ray source and detector remain fixed. This stable geometry ensures repeatability and reliable measurement results.

- Radiograph Acquisition: Multiple 2D radiographic projections are captured at defined angular increments. Each image records X-ray attenuation across the component’s internal and external structures.

- 3D Reconstruction: Advanced reconstruction algorithms convert the radiographs into a high-resolution 3D voxel model representing the complete volume of the part.

- Surface Determination: Material boundaries are identified using thresholding and edge-detection algorithms to extract an accurate surface model suitable for dimensional measurement.

- Measurement and Evaluation: The extracted geometry is analyzed using CT metrology software to perform dimensional measurements, wall thickness analysis, GD&T evaluation, and direct 3D CAD comparison, supporting confident engineering and quality decisions.

What are the applications of CT measuring services across various industries?

CT measuring services have become an indispensable tool in industries where precision, reliability, and non-destructive inspection are critical. Some of the key applications include:

- Aerospace: Inspecting turbine blades, engine components, and composite structures for internal defects, porosity, or structural integrity without damaging expensive parts.

- Automotive: Ensuring quality in engine parts, castings, and complex assemblies; reverse engineering components for redesign or optimization.

- Medical Devices: Verifying the internal geometry and dimensional accuracy of implants, surgical tools, and prosthetics to meet strict regulatory standards.

- Electronics: Inspecting PCBs, connectors, and intricate assemblies to detect internal voids, misalignments, or manufacturing defects.

- Industrial Manufacturing: Analyzing heavy machinery components, forged or cast parts, and multi-material assemblies for defects, wear, or tolerance verification.

- Research and Development: Supporting prototyping, design validation, and material analysis across various high-tech and industrial projects.

Why Choose RA Global?

RA Global Tech Solutions, CT Measuring Services provides a fast, flexible, and non-destructive solution for dimensional measurement of complex components and hidden internal geometries commonly encountered in modern manufacturing. Unlike traditional inspection methods that rely on cutting or sectioning, adding time, cost, and operational complexity, CT measurement enables complete internal and external dimensional evaluation in a single 3D scan.

Using advanced industrial CT technology, RA Global Tech Solutions delivers high-precision volumetric data that supports accurate wall thickness measurement, quantitative detection of cracks, pores, voids, and inclusions, as well as verification of complex geometries and assembly integrity. Our CT measuring services are application-specific, ensuring efficient data acquisition and reliable evaluation across a wide range of materials and component types.

- Experience: Years of expertise in serving automotive industries with a team of seasoned professionals

- Comprehensive Services: Wide range of services, including product design and development, 3D printing, product analysis, 3D laser scanning, and reverse engineering

- Quality and Innovation: Commitment to providing high-quality solutions, fostering innovation, and utilizing cutting-edge technologies

Frequently Asked Questions

What is CT measuring?

CT measuring is a nondestructive testing technology that uses X-rays to create detailed 3D images of an object's internal and external structures.

What are the benefits of CT measuring services?

CT measuring services offer high accuracy, nondestructive testing, and internal structure analysis, making them ideal for complex components.

What types of products can be measured with CT scanning?

CT scanning can measure complex components, multi-material parts, and small products with high precision and accuracy.

How does CT measuring work?

CT measuring works by using X-rays to capture detailed images of an object's internal and external structures, which are then reconstructed into 3D digital models.

Why choose CT measuring services?

CT measuring services offer expertise, state-of-the-art equipment, and quality assurance, ensuring accurate and reliable results for complex components.