3D Reverse Engineering

What is 3D reverse engineering service?

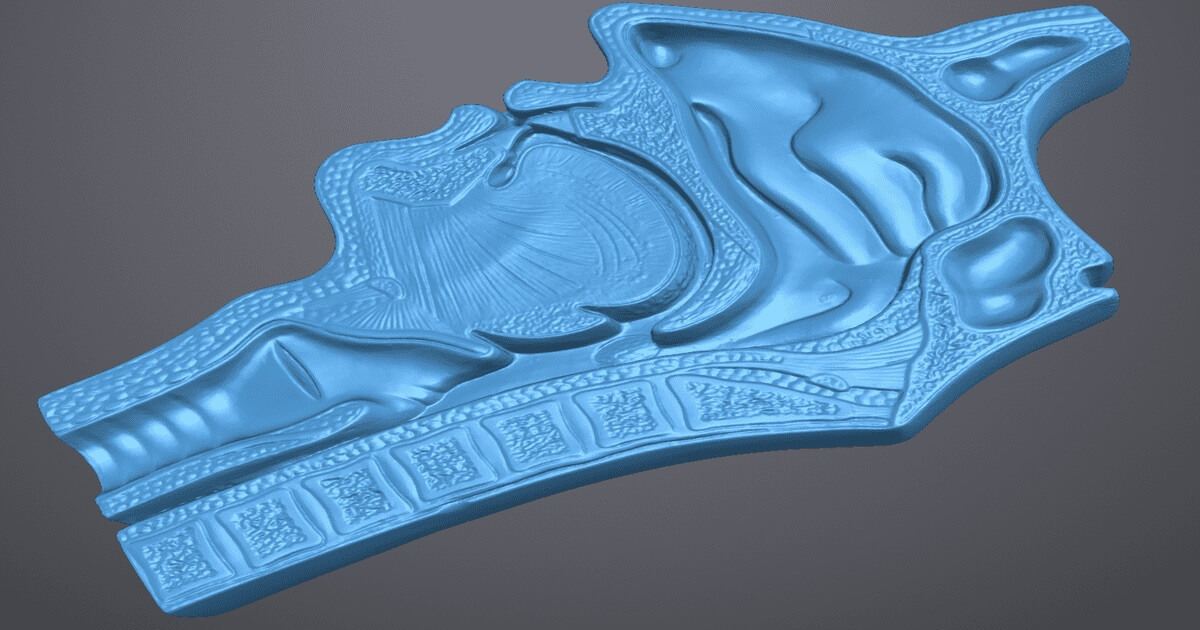

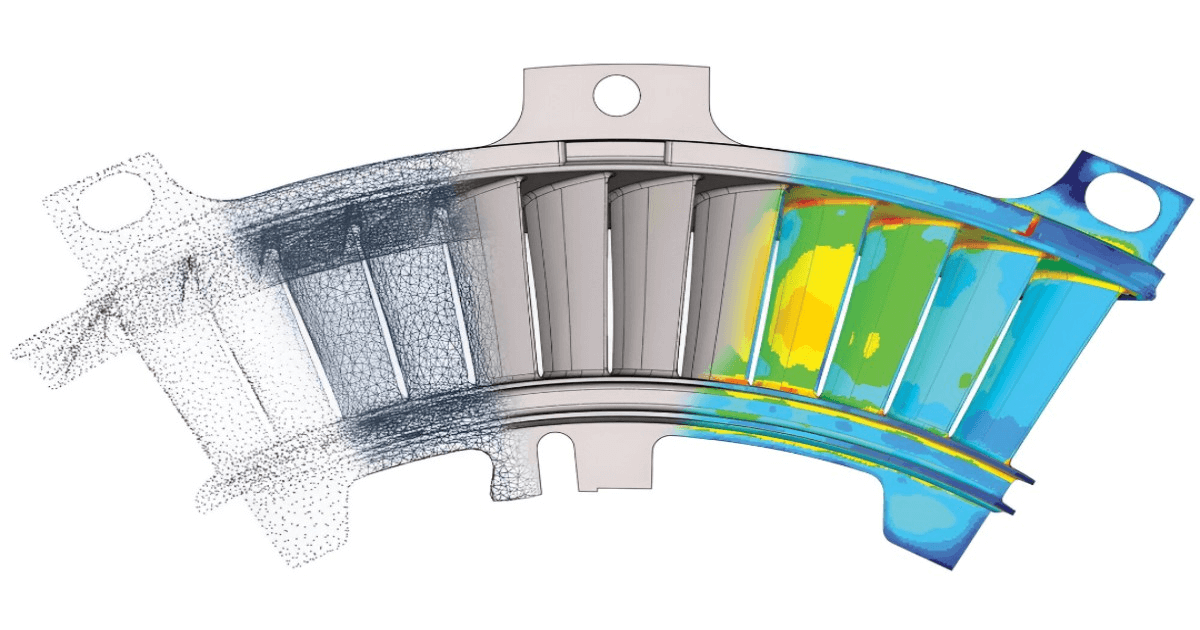

3D reverse engineering is the process of capturing the geometry of an existing physical object and converting it into an accurate digital 3D model. Using technologies such as 3D scanning or coordinate measurement, detailed surface and dimensional data is collected and processed into 3D CAD models that can be analyzed, modified, or reproduced.

3D reverse engineering services utilize advanced 3D scanning techniques to capture the dimensions and geometry of physical objects, enabling the recreation or reproduction of complex parts and products. The technique of 3D scanning involves using equipment that measures the distance between the 3D scanner and the object using a 3D laser or other light source to digitally record information about the shape of the thing. Very small things all the way up to full-size aeroplans can be captured with 3D scanning. We can quickly inspect parts thanks to 3D laser scanners, which can gather tens of thousands of points per second.

Key Aspects of 3D reverse engineering service:

- 3D Scanning: Capture physical objects geometry and dimensions using advanced 3D scanning techniques

- Data Processing: Clean and process 3D scanned data to create a usable digital model

- Modeling and Refining: Create a precise digital model and refine it to meet specific requirements

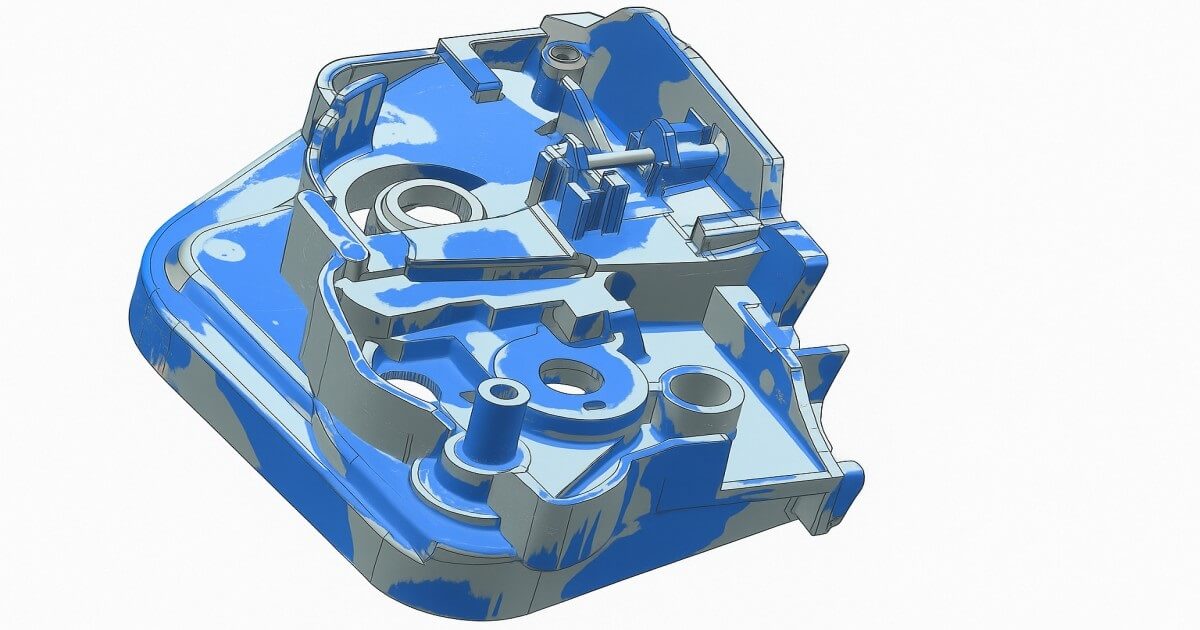

- Design Analysis and Optimization: Analyze and improve existing designs for enhanced performance, efficiency, and functionality

- Prototyping and Testing: Create digital models for simulation, testing, and validation

- Manufacturing and Production: Streamline production, reduce costs, and improve product quality

These aspects enable businesses to harness the power of 3D reverse engineering for innovation, efficiency, and growth.

Why 3D reverse engineering services is important?

3D reverse engineering services play a crucial role in modern product development and manufacturing. They allow companies to recreate complex geometries, analyze and improve existing designs, and produce high-quality products with precision and accuracy. By utilizing 3D scanning and modeling techniques, businesses can reduce the time and cost associated with product development, while also improving product performance and reliability. This technology is particularly valuable in industries where legacy designs are prevalent, or where products have complex geometries that are difficult to measure using traditional methods. Overall, 3D reverse engineering services provide a powerful tool for companies to drive innovation, efficiency, and growth.

What are the common challenges in 3D reverse engineering services ?

3D reverse engineering services face several common challenges, including ensuring data accuracy, particularly for complex geometries and dimensions. Managing large datasets, noise reduction, and data optimization can also be daunting tasks. Additionally, dealing with intricate shapes, internal structures, and hidden features poses significant complexity. Scanning materials with reflective, transparent, or absorbent properties can be problematic. Creating accurate 3D CAD models from scanned data, handling complex surfaces, and ensuring compliance with intellectual property laws and regulations are also crucial considerations. Finally, verifying the accuracy and precision of reverse-engineered models is essential for quality control.

Related Services

- 3D Scanning Services: Capturing precise 3D data of physical objects.

- CAD Modeling Services: Creating accurate digital models from scanned data.

- 3D Printing Services: Rapid prototyping and production of complex geometries.

- Product Design Services: Enhancing and optimizing product designs.

- Rapid Prototyping Services: Creating functional prototypes for testing and validation.

These related services complement 3D reverse engineering, enabling businesses to streamline product development, improve design efficiency, and reduce time-to-market.

The Process

The Process of 3D reverse engineering services

- 3D Scanning: Capture physical objects geometry using 3D scanning techniques.

- Data Processing: Clean and refine scanned data to remove noise and imperfections.

- 3D Modeling: Create a digital model from processed data.

- Model Refining: Refine and optimize the 3D model for accuracy and functionality.

- Design Analysis: Analyze and evaluate the design for performance, efficiency, and manufacturability.

- Validation: Verify the accuracy of the 3D reverse-engineered model against the original object.

- Final Output: Deliver the final 3D model, often in 3D CAD format, for manufacturing, prototyping, or further development.

This process enables the creation of accurate digital models from physical objects, facilitating design improvement, replication, or innovation.

3D reverse engineering methodologies

- Product Analysis: RA Global employs skilled reverse engineers who can analyze and evaluate the design, components, and functionality of a product or system. Through their expertise, they can dissect and understand how the product works, allowing clients to gain valuable insights into its inner workings.

- Documentation: Reverse engineering often involves creating detailed documentation and specifications of the analyzed product. At RA Global, we can assist in generating accurate as-built documentation, including 3D CAD models, technical drawings, and assembly instructions. This documentation is essential for replication, modification, or further development.

- 3D Scanning: RA Global utilizes advanced 3D scanning technologies to capture the physical dimensions and geometry of objects. This enables them to create precise digital models, which can be used for analysis, modification, or replication. Metrology techniques ensure accuracy and reliability in the measurements taken.

- Reconstruction: Convert the processed scan data into a 3D model. This involves creating a surface model by connecting the points or vertices from the point cloud or mesh data. Various software tools, such as 3D CAD software, are used to reconstruct the object digitally. If required, add parametric features to the 3D model, allowing for flexibility in design modifications or adaptations.

- Competitive Analysis: RA Global helps businesses gain a competitive edge by conducting reverse engineering on competitors products. By studying their features, design, and manufacturing processes, clients can gain valuable insights for product improvement, innovation, or market differentiation.

- Rapid Prototyping: Rapid prototyping process is often utilized in reverse engineering to efficiently recreate physical objects or systems based on the data obtained from the analysis.

Our team of experts in reverse engineering services generates 3D CAD models from existing objects (as-built), whether to determine the original design intent, modernize manufacturing processes, or design a new part to fit a legacy part, for instance.

We help our customers by utilizing the appropriate reverse engineering tools, to deliver 3D CAD models and STL files at any point of the Product Development process.

- 3D modeling of objects of all sizes

- Using generic or native file formats for parametric 3D modeling

- 3D reconstruction scanning information, sketches, 2D drawings, etc.

- Hybrid modeling

- Design modification from existing objects

- Data preparation for simulation

- Class-A surface modeling and Class-B surfacing

- Part design for injection molding (e.g. draft angle analysis, shrinkage)

What are the applications of 3d reverse engineering services across various industries?

3D reverse engineering services have numerous applications across various industries, including:

- Automotive Industry: Analyzing and refining existing car part geometries to enhance aerodynamics or produce spare parts for discontinued models. Creating digital models for design modification, part replacement, and optimization.

- Aerospace Industry: Analyzing and refining intricate aircraft and spacecraft components to increase safety and facilitate maintenance. Using 3D scanning and 3D CAD modeling to identify weaknesses and defects.

- Manufacturing Industry: Creating prototypes and streamlining production processes using 3D scanning and 3D CAD modeling. Optimizing component production and identifying defects or weak points.

- Medical Device Industry: Reverse engineering medical devices to improve design, functionality, and compatibility. Creating customized medical devices or implants using 3D printing.

- Heavy Equipment and Firearms Industries: 3D Reverse engineering complex parts and systems to improve design and functionality. Creating accurate digital models for redesign, quality verification, or replication.

- Forensic and Architectural Industries: Using 3D scanning and reverse engineering for crime scene reconstruction and analysis. Creating detailed digital models of buildings and structures for restoration or renovation.

- Product Development: Analyzing existing products to identify areas for improvement and optimize design. Creating new products or modifying existing ones using 3D reverse engineering techniques.

- Legacy Part Reproduction: Creating digital models of legacy parts for reproduction or replacement. Streamlining production processes and reducing costs.

- Quality Control and Inspection: Verifying product dimensions and tolerances using 3D scanning. Identifying defects or deviations from design specifications

Why Choose RA Global?

At RA Global Tech Solutions, we have been providing industry leading 3D Scanning and 3D Reverse Engineering Services in Mumbai to a variety of industries since 2013. Our expertise in capturing data for Marine, Industrial, Manufacturing, and Automotive applications ensures you have an expert reverse engineer you can rely on.

- Expertise: RA Globals team of experienced professionals delivers high-quality 3D reverse engineering services

- Advanced Technology: Utilization of cutting-edge software and equipment ensures accurate and efficient results

- Customized Solutions: Tailored services meet specific client needs and requirements

- Quality Assurance: Rigorous quality control processes guarantee precise and reliable outcomes

- Innovative Approach: RA Globals team stays up-to-date with industry trends and best practices

- Competitive Pricing: Cost-effective solutions without compromising on quality

- Timely Delivery: Projects completed within agreed-upon timelines

Contact Us today for your 3D Scanning and 3D Reverse Engineering requirements.

Frequently Asked Questions

What is 3D reverse engineering?

It involves analyzing existing parts or products to create accurate 3D CAD models, enabling reproduction, redesign, or improvement of complex components.

Why choose RA Global for 3D reverse engineering?

We combine advanced 3D scanning, expert 3D CAD modeling, and industry experience to deliver precise, ready‑to‑manufacture digital models efficiently.

Which industries need 3D reverse engineering?

Automotive, aerospace, industrial equipment, manufacturing, and heritage restoration often use it to recreate, update, or improve parts and assemblies.

Can you work from physical samples only?

Yes! We can scan and measure physical components directly, even without original drawings, to build detailed and editable 3D CAD models.

What deliverables do you provide?

We supply 3D CAD models, 2D drawings, and detailed documentation in formats compatible with your design, manufacturing, and quality processes.