CNC Machining Services

What is CNC machining services?

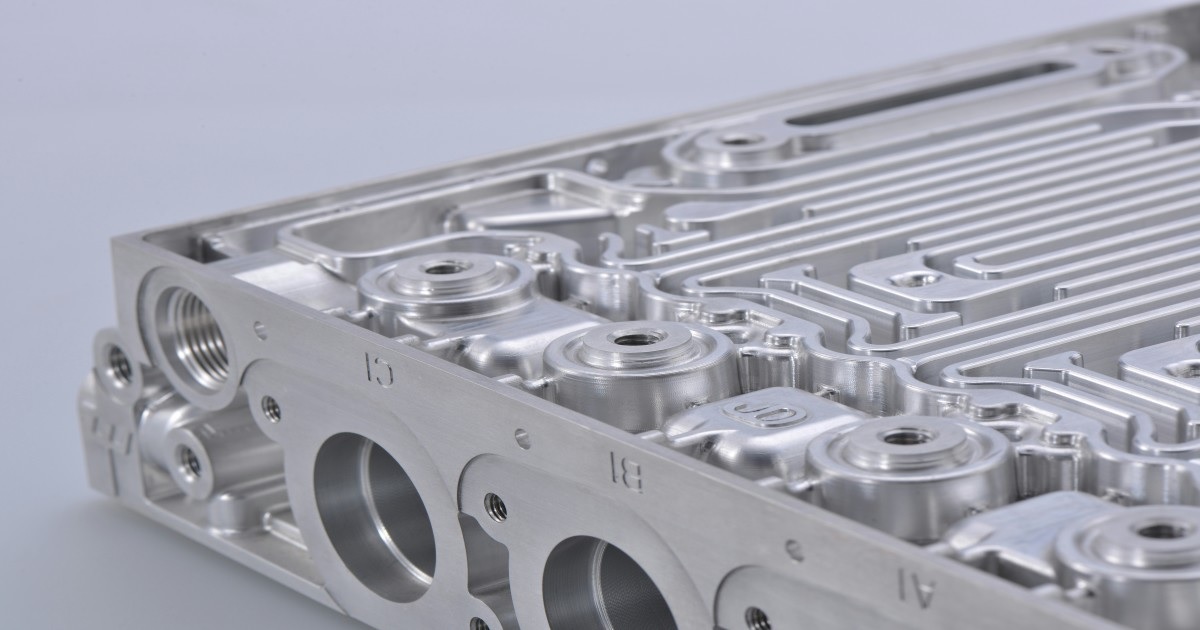

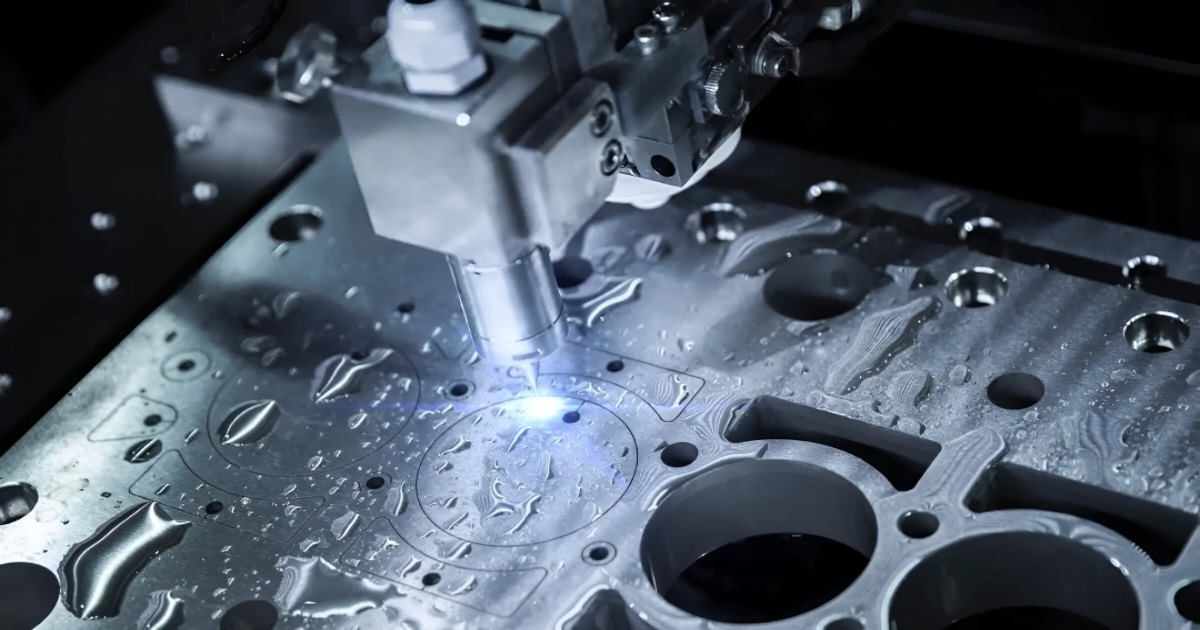

CNC machining (Computer Numerical Control machining) is a manufacturing process in which computer-controlled machines precisely remove material from a workpiece to produce parts with high accuracy and repeatability. The machines follow programmed instructions derived from CAD/CAM data to perform operations such as milling, turning, drilling, and grinding.

CNC machining services are the most important with essential benefits in manufacturing industries. It is a more precise and repeatable process, which can lead to higher quality parts. It is also a more versatile process, as CNC machines can be programmed to produce a wide variety of parts. Additionally, CNC machining is a more efficient process, as it can produce parts faster and with less waste.

Key Aspects of CNC machining services:

- Precision and Accuracy: CNC machining is renowned for its micron-level precision. The automated control of cutting tools ensures consistent accuracy across all parts, even for complex geometries or high-tolerance components

- Automation and Efficiency: Since CNC machines are computer-controlled, they can operate continuously with minimal human intervention. This leads to faster production cycles, reduced labor costs, and improved productivity

- Material Versatility: CNC machines can perform various operations like milling, turning, drilling, and grinding on different materials

- Complex Geometry Capability: Modern CNC machines, especially 4-axis and 5-axis systems, can produce intricate shapes and contours that are impossible with manual machining. This is vital for components that require multiple angles or detailed finishes

- Consistency and Repeatability: Once a design is programmed, the machine can replicate it perfectly again and again. This repeatability ensures uniform quality, which is essential for mass production and critical applications

- Cost-Effectiveness: While the initial setup and programming may take time, CNC machining offers low operational costs and minimal material waste in the long run. It’s particularly efficient for medium to high-volume production

Why CNC Machining services is important?

CNC machining services play a vital role in modern manufacturing due to their precision, efficiency, and reliability. These computer controlled systems ensure high dimensional accuracy, minimizing human error and reducing material waste. The automation in CNC machining enables faster production cycles, helping industries meet tight deadlines without compromising quality.

Moreover, CNC technology supports rapid prototyping and customized production, making it ideal for developing and testing complex designs. Its ability to maintain consistent quality across large production runs ensures that every component meets exact specifications. CNC machines can also create intricate geometries that are nearly impossible to achieve manually.

With the capability to work across a wide range of materials including metals, plastics, and composites and handle both low-volume prototypes and high volume production, CNC machining has become indispensable for industries such as aerospace, automotive, medical, and electronics.

What are the common challenges in CNC Machining services?

CNC machining services face several challenges that can affect efficiency, accuracy, and cost effectiveness. One of the most common issues is tool wear and breakage, which can reduce machining precision and lead to unexpected downtime. Material selection also poses difficulties, as different materials have varying properties and machining behaviors that must be carefully managed to achieve optimal results. Maintaining tight tolerances and producing complex geometries with the desired surface finish requires precise programming, high-quality tooling, and consistent calibration.

Related Services

At RA Global Tech Solutions, our CNC Machining Services are complemented by a range of advanced engineering and manufacturing solutions designed to meet diverse industrial needs. These include:

- Reverse Engineering: We use advanced 3D scanning and CAD modeling to accurately recreate existing components, enabling product improvement, design optimization, and efficient reproduction of legacy parts.

- 3D Printing and Rapid Prototyping: Our additive manufacturing capabilities allow for quick prototyping and low-volume production, helping clients validate designs and reduce time-to-market.

- 3D Laser Scanning and CAD Conversion: High-precision laser scanning captures detailed geometries of physical objects, which we convert into accurate 3D CAD models for further analysis, modification, or manufacturing.

- CMM Inspection Services: Coordinate Measuring Machine (CMM) inspection ensures every component meets the highest standards of dimensional accuracy and quality through precise measurement and validation.

- Product Design and Development: From concept to production, our design team leverages advanced CAD/CAM tools to deliver innovative and manufacturable product solutions across industries.

The Process

The CNC machining process follows a systematic workflow designed to ensure accuracy, efficiency, and high-quality results. It typically involves the following key steps:

- Design: The process begins with creating a digital 3D model of the part using CAD (Computer-Aided Design) software. This model defines all dimensions, tolerances, and features.

- Programming: The CAD model is converted into CNC code (G-code), which provides the machine with precise instructions for cutting, tool movements, and speeds.

- Setup: The CNC machine is prepared by loading the raw material, securing it with fixtures or vices, and installing the required cutting tools. Proper setup ensures stability and accuracy during machining.

- Machining: The programmed instructions are executed, and the CNC machine performs operations such as milling, drilling, turning, or grinding to shape the material into the desired part.

- Inspection: Once machining is complete, the part undergoes quality inspection to verify dimensions, surface finish, and tolerances often using precision instruments or CMM (Coordinate Measuring Machine) systems.

- Finishing: Additional finishing processes, such as deburring, sanding, anodizing, or coating, are applied to enhance durability and appearance.

- Assembly: If required, multiple machined components are assembled to create a complete product or subassembly.

This structured process we allows RA Global Tech Solutions to deliver precise, consistent, and efficient production of complex parts and components for industries like aerospace, automotive, medical, and electronics.

Our best CNC machining services include:

- Design and development of CNC machining tools: Our team of experts designs and develops custom CNC machining tools tailored to specific project requirements. This includes: Creating detailed CAD designs and simulations, Selecting suitable materials and tooling, Developing optimized machining strategies, Testing and validating tool designs

- Manufacturing of CNC machined parts: We utilize state-of-the-art CNC machining equipment to manufacture high-quality parts with precision and accuracy. Our capabilities include: Milling: 3-axis, 4-axis, and 5-axis milling for complex geometries, Turning: CNC turning for producing cylindrical parts, Drilling: Precision drilling for accurate hole placement, Grinding: Surface grinding for achieving precise finishes

- Quality control and inspection: To ensure that our CNC machined parts meet the highest standards, we implement rigorous quality control and inspection processes. This includes: Dimensional inspection: Verifying part dimensions and tolerances, Surface finish inspection: Evaluating surface finishes and textures, Material inspection: Verifying material composition and properties, Functional testing: Testing parts for functionality and performance

- Delivery of finished parts: Once the CNC machined parts have passed quality control, we package and deliver them to customers worldwide. Our delivery options include: Standard shipping: Reliable and cost-effective shipping options, Expedited shipping: Priority shipping for urgent projects, Custom packaging: Tailored packaging solutions to meet specific requirements

What are the applications of CNC machining services across various industries?

- Aerospace: Machining complex aircraft components, engine parts, and satellite components. Ensures lightweight, high-strength, and precise parts for safety and performance.

- Automotive: Producing high-precision parts such as engines, transmission components, and custom accessories. Improves vehicle performance, reliability, and efficiency.

- Medical: Creating medical implants, surgical instruments, and diagnostic equipment components. Supports life-saving procedures with high accuracy and biocompatibility.

- Industrial: Machining parts for machinery, equipment, and tooling. Enhances operational efficiency and durability in industrial applications.

- Electronics: Producing components for electronic devices, including connectors, housings, and heat sinks. Ensures precise assembly and reliable functionality of devices.

- Defense: Manufacturing military equipment components, armor plating, and specialized parts. Provides durability and precision for critical defense applications.

- Energy: Machining components for oil & gas equipment, renewable energy systems, and nuclear power plants. Supports energy production with high-precision, robust components.

- Aerospace & Defense: Producing complex components for aircraft, spacecraft, and defense systems. Enables innovation and reliability in high-performance environments.

- Consumer Products: Producing parts for appliances, sporting goods, and musical instruments. Delivers quality, durability, and consistency in everyday products.

- Prototyping: Rapid prototyping for product development and testing. Accelerates innovation and reduces time-to-market for new products.

Why Choose RA Global?

RA Global offers tailored CNC machining solutions with advanced technology and expertise, ensuring high quality parts that meet specifications and deadlines, increasing productivity, and reducing costs for industries like aerospace, automotive, medical, and industrial application.

- Experienced Team: Our engineers and technicians bring extensive expertise in designing and developing CNC machining tools for a wide range of applications.

- State of the Art Facility: Equipped with advanced CNC machines and cutting-edge technology, our manufacturing facility produces high-quality, precision machined parts, even in large volumes.

- Comprehensive Services: We offer end to end solutions, including the design and development of CNC tools, manufacturing of components, rigorous quality control, and timely delivery.

- Custom Solutions: We provides tailored CNC machining services to handle complex geometries and high precision parts, optimizing productivity while reducing costs.

RA Global is a prominent leader in the industry and provides the best CNC machining services. We have over 7 years of experience in the industry, and we offer a wide range of services to meet the needs of our customers. If you are considering using CNC machining to produce parts, RA Global is the perfect partner for you. We have the experience, expertise, and capabilities to meet your needs and exceed your expectations. Take a moment and scroll through all our solution here.

If you are looking for a reliable and experienced provider of the best CNC machining services, contact RA Global today and discuss your requirements. We would be more than glad to see you on our portfolio list.

Frequently Asked Questions

What are CNC machining services?

We produce precise metal or plastic parts by cutting, milling, or turning using computer-controlled machines based on your CAD designs.

Why choose RA Global for CNC machining?

We combine advanced CNC technology, skilled machinists, strict quality checks, and competitive pricing to deliver reliable, high‑quality custom parts.

Which industries use CNC machining?

Aerospace, automotive, industrial equipment, medical devices, and consumer products often need custom-machined prototypes and production components.

Can you work from CAD models or drawings?

Yes! Share your CAD files or technical drawings, and we will manufacture parts to your exact specifications and required tolerances.

What materials can you machine?

We work with aluminum, steel, stainless steel, brass, plastics, and other metals, based on your project’s design and performance requirements.