3D Scanning Services

Contact us to learn more about how we can deliver the best possible results for your 3D Scanning.

Contact us to learn more about how we can deliver the best possible results for your 3D Scanning.

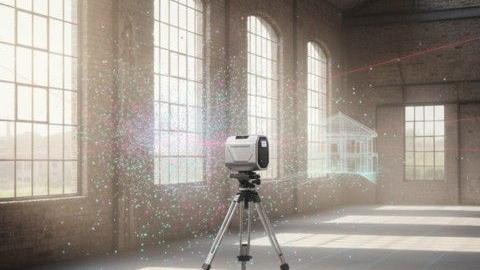

Our architectural 3D scanning captures buildings and interiors with accuracy, creating precise 3D models for site documentation, renovation planning, visualization, and digital archiving.

Our automotive 3D scanning solutions capture every curve and detail with high precision, creating accurate digital models for design validation, prototyping, inspection, and visualization.

Our jewelry 3D scanning captures intricate details with precision, converting physical jewelry into accurate 3D models for replication, customization, inspection, and digital archiving.

Our object 3D scanning converts physical objects into detailed and accurate 3D models. These models are ideal for planning, visualization, and presentations, helping you showcase the concepts.

Our plant 3D scanning captures the full structure and details of industrial plants. The precise digital models help with planning, visualization, and maintenance.

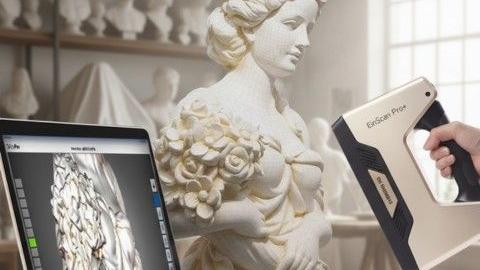

Our sculpture 3D scanning captures every detail of physical artworks. The resulting precise digital models are ideal for archiving, restoration, and exhibition planning.

Our ship 3D scanning captures hulls and onboard components with accuracy, creating precise 3D models for design validation, maintenance planning, retrofitting, and digital archiving.

Our toy 3D scanning services capture fine details with high precision, converting toys, figurines, and collectibles into accurate 3D models for replication, prototyping, inspection, and digital archiving.

Our windmill 3D scanning captures turbines, blades, and structural components in high detail, creating accurate 3D models for maintenance planning, performance analysis, and digital archiving.

Get a Call Back

Leave us your details our team will get in touch soon

© 2026 RA Global Tech Solutions

Site design and developed by Rajkar Global