The way technological advancement is reshaping the industries' design, innovation, and manufacturing, were reverse engineering has emerged as one of the most powerful tools driving industrial modernization with shrinking product lifecycles, growing demand for customization, and increasing pressure to deliver high-quality products, businesses across the globe.

A niche engineering practice has now evolved into an essential process for product development, 3D CAD modeling, motion analysis, stack-up analysis, design optimization, and innovation-driven redesign. As industries embrace 3D digitalization and reverse engineering, 3D scanning is playing a central role in bridging the gap between physical and digital worlds.

Let’s explore what reverse engineering is, its growing relevance in modern supply chains and how it is transforming various industrial sectors.

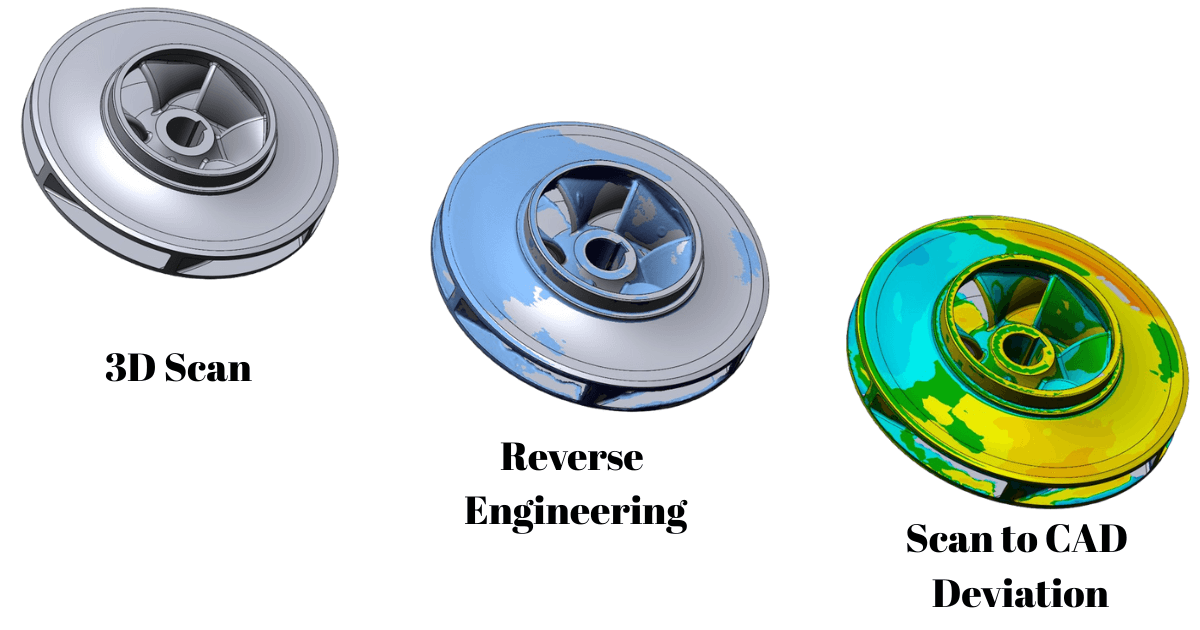

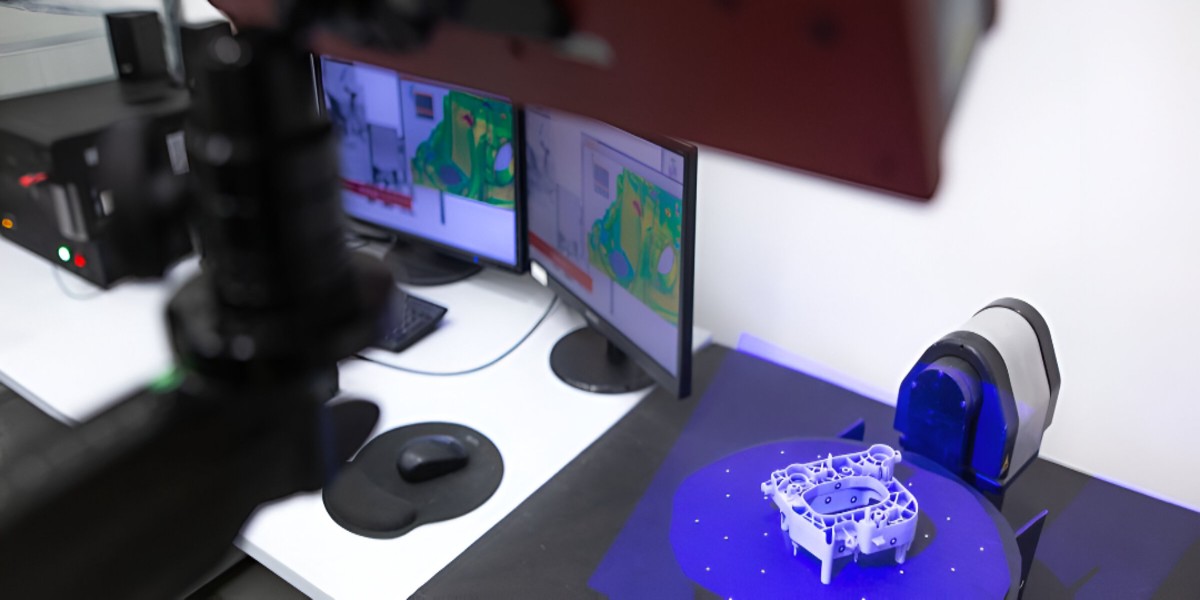

Reverse engineering is the process of capturing the physical geometry, features, and functional characteristics of an existing product to create a detailed 3D digital model. Instead of doing manual measurements, engineers start with using advanced technologies such as 3D laser scanning, profile projectors, CMM measuring mechanisms, point cloud processing, and surface reconstruction with parametric CAD modeling. These tools convert physical objects into highly accurate CAD models that can be used for optimization, redesign, remanufacturing, and quality validation.

At RA Global, we integrate advanced technology with deep engineering expertise to deliver exceptionally precise reverse engineering solutions. Our team converts complex physical components into Class A surface, editable, and manufacturable CAD models with high accuracy. RA Global offers reverse engineering services in Germany, Italy, Norway and Europe with superior accuracy results.

The growing importance of reverse engineering in most advanced and fast-moving technology is driven by challenges such as discontinued parts, long lead times, imported dependencies, and inconsistent quality. Reverse engineering offers an efficient solution by enabling companies to recreate obsolete or unavailable components, reduce dependability on overseas suppliers, improve accuracy in retrofitable part manufacturing, and maintain consistency across production batches. It also helps convert physical components into digital inventories while supporting localized manufacturing and faster turnaround times.

Reverse engineering has become indispensable across multiple industries due to its ability to enhance design accuracy, reduce costs, and revive legacy systems. Key industrial applications include:

Modern reverse engineering is all about precision, flexibility, and usability of the most advanced technologies. One of its standout features is high-accuracy 3D scanning, which can capture even the most intricate shapes, curves, and details of complex parts. Combined with point cloud and mesh processing, raw scan data is cleaned, aligned, and optimized, ready to be converted into 3D CAD design, parametric and surface CAD modeling. This data becomes fully editable CAD designs that can be used for redesign, manufacturing, or DFMEA. Beyond geometry, reverse engineering also provides insights into materials and manufacturing processes, helping engineers understand how a part was originally made. And the best part? These CAD models are fully compatible with CNC machining and 3D printing, making it easy to bring designs back to life in the real world.

Reverse engineering services bring a lot of advantages for modern industries. It allows companies to reproduce parts without original drawings, making it ideal for legacy conversion for lost or outdated documentation. By leveraging 3D scanning and digital modeling, reverse engineering accelerates product development, reduces design cycles, and speeds up prototyping. It also improves design efficiency by quick 3D CAD conversion, optimizing structures, enhancing performance, and minimizing material usage. Furthermore, reverse engineering offers cost-effective manufacturing, as digital rebuilding avoids expensive redesigns from scratch and repeatability of manufacturing to benchmark the product. Quality control is enhanced through precise comparison of scanned geometry with CAD models, ensuring dimensional accuracy. It also helps reduce lead times, enabling rapid part replacement and meeting deadlines for remanufacturing.

Reverse engineering is redefining how industries design, replicate, and optimize products. Whether it’s about replacing obsolete components, improving product performance, DFMEA, or supporting prototyping, reverse engineering has become a cornerstone of modern industrial innovation.

By speeding up the 3D CAD modelling and CAD conversion, reverse engineering empowers industries to unlock new levels of efficiency, accuracy, and competitiveness, making it an essential technology for the future.

Introduction 3D laser scanning is transforming industries with its ability to capture high-resolution 3D data in real time. From infrastructure and architecture to environmental analysis and urban planning, this powerful technology is being adopted across a wide range of applications.

3D laser scanning is an advanced technology that uses LiDAR (Light Detection and Ranging) to capture precise measurements of objects and environments. By emitting 3D laser pulses that bounce off surfaces, it calculates distances and creates accurate 3D models or point clouds. This method is widely used in construction, architecture, engineering, and manufacturing for tasks like as-built documentation, design planning, and quality control, offering speed, accuracy, and reduced human error in data collection.

This method can be mounted on drones, vehicles, or tripods for different applications.

These point clouds form the basis of highly detailed digital maps and models.

3D laser scanning is used in a wide variety of industries, including:

In the middle of all these sectors, 3D laser scanning plays a critical role in improving data accuracy and operational efficiency.

RA Global Tech Solutions, located in Malad West, Mumbai, offers state-of-the-art 3D laser scanning services across multiple industries. Their expert team leverages the latest scanning equipment and software to deliver precise, timely, and actionable data.

Whether it's a construction site in Mumbai or a forest survey in another state, RA Global ensures top-tier service.

India’s smart city mission is opening up new opportunities for 3D laser scanning. Urban infrastructure planning, utility mapping, and traffic management can all benefit from high-resolution 3D data. RA Global Tech Solutions is contributing to this mission by supporting government and private projects with their cutting-edge laser technology.

As technology progresses, 3D laser scanning is expected to become more affordable and compact. Integration with AI and machine learning will allow better feature detection, object classification, and predictive analytics.

Upcoming trends include:

3D laser scanning is a powerful tool that supports faster, safer, and more precise data collection across various industries. From construction and mining to smart city planning and environmental monitoring, the benefits of this technology are immense. RA Global Tech Solutions in Mumbai offers professional 3D laser scanning services designed to deliver accurate results tailored to specific project needs. If you are seeking reliable 3D laser scanning support, RA Global Tech Solutions is ready to assist with the right tools and expertise.

In an era where precision drives innovation, industries are continually seeking technologies that enable accuracy, efficiency, and cost-effectiveness. One such groundbreaking advancement is 3D laser scanning, which has rapidly gained traction across multiple sectors. The growing demand for meticulous detailing in design, construction, and manufacturing has positioned 3D laser scanning service Pune as a go-to solution for engineers, architects, manufacturers, and urban developers. This technology not only captures real-world data with incredible accuracy but also transforms it into detailed, digital 3D models, paving the way for smarter decisions and faster project execution.

3D laser scanning is a high-precision technology that utilizes laser beams to measure and map the physical dimensions of objects and environments. It works by emitting lasers that bounce off surfaces and return to the scanner, calculating distances based on time and angle. The result is a dense collection of data points, known as a point cloud, which forms a comprehensive digital replica of the scanned object or space.

These point clouds are processed using advanced software to generate accurate 3D models that can be used in applications ranging from architectural design to industrial quality control. With businesses in Pune increasingly seeking high-precision solutions, the popularity of 3D laser scanning service in Pune is growing at a remarkable pace.

Adopting 3D laser scanning comes with a host of advantages that directly improve operational workflows and enhance project outcomes. Here are some of the key benefits:

Understanding the process behind 3D laser scanning service Pune provides insight into its effectiveness:

For businesses in Pune looking for reliable and efficient 3D laser scanning, RA Global Tech stands out as a trusted provider. Known for their commitment to quality and precision, they offer end-to-end solutions tailored to a variety of industries.

In addition to offering 3D laser scanning services in Pune, RA Global Tech also supports innovation through 3D-printed prototype services in Mumbai. Whether you are a product designer or an engineer, their prototyping solutions can help bring concepts to life with fast, high-quality prints.

If you are located near Malad and searching for "3D scanners near me," RA Global Tech also caters to clients in this region, providing local access to global-grade scanning technology. Their expertise ensures that your scanning needs, be it for reverse engineering or detailed modeling, are met with professionalism and precision.

3D laser scanning is revolutionizing how businesses design, build, and innovate. From accurate site mapping to high-quality product design, this technology offers a versatile and reliable solution for today’s precision-driven industries. As demand continues to grow, 3D laser scanning service Pune stands out as an essential tool for anyone involved in architecture, engineering, manufacturing, and more.

For businesses in Pune and surrounding areas, RA Global Tech provides top-tier scanning services backed by experience, technology, and a commitment to excellence. Whether you are planning a complex construction project, preserving historical landmarks, or developing the next big product, RA Global Tech’s 3D scanning solutions offer the accuracy and efficiency you need to succeed.

In today’s competitive landscape, accuracy and precision are paramount, especially in construction, manufacturing, and design industries. 3D Laser scanning services have emerged as a game-changing solution for capturing detailed spatial data. In Mumbai, RA Global Tech provides cutting-edge 3D laser scanning solutions, enabling businesses to create accurate digital models that aid in efficient planning and execution.

3D laser scanning services involve using advanced equipment to capture precise measurements of physical spaces or objects. The scanners project lasers onto a surface, recording millions of data points, known as point clouds. This data is then used to create highly detailed 3D models.

Accuracy and Precision: Captures data with millimeter-level precision.

Time Efficiency: Reduces the time spent on manual measurements.

Comprehensive Documentation: Offers a complete digital record of the scanned environment.

Cost-Effective Solutions: Minimizes errors and rework by providing accurate data upfront.

3D laser scanning is versatile and benefits various industries:

Architecture and Construction: Create accurate floor plans and elevation models, Document as-built conditions for renovations and restorations.

Manufacturing and Engineering: Reverse engineering of complex parts, Quality control and inspection of components.

Heritage Preservation: Document and preserve cultural landmarks, Create digital archives for future reference.

Oil and Gas Industry: Scan and map offshore structures, Ensure safety and compliance in hazardous environments.

Data Collection: The scanner emits laser beams that reflect off surfaces, capturing spatial data.

Point Cloud Generation: The collected data forms a point cloud, representing the object's geometry.

Model Creation: Software processes the point cloud into a 3D model, which can be used for analysis and planning.

RA Global Tech is a leader in 3D laser scanning services, offering advanced solutions tailored to your needs. Here’s why they stand out:

State-of-the-art equipment: They use the latest technology to ensure accurate results.

Expert Team: Skilled professionals manage the entire scanning process.

Comprehensive Solutions: From data capture to model creation, they provide end-to-end services.

Experience: Ensure the company has expertise in your industry.

Technology: Look for providers that use advanced scanning equipment.

Data Security: Verify their protocols for handling and storing sensitive data.

Customer Support: Choose a provider with responsive and knowledgeable support staff.

Non-Invasive: Scanning does not require physical contact, making it ideal for fragile objects.

Fast and Efficient: Collects vast amounts of data quickly.

High-Level Detail: Captures intricate details that manual methods might miss.

Too Expensive: While initial costs may seem high, the long-term savings from reduced errors and rework justify the investment.

Only for Large Projects: 3D laser scanning is scalable and suitable for projects of all sizes.

Difficult to Use: Professional services like RA Global Tech handle the complex aspects, delivering user-friendly outputs.

Case Studies: Real-World Applications of 3D Laser Scanning

Construction Site Mapping: A local construction firm used RA Global Tech’s services to scan a site, reducing project delays by 20%.

Industrial Plant Inspection: A manufacturing unit leveraged 3D scanning to inspect machinery, identifying critical wear and tear.

As technology advances, 3D laser scanning services will continue to evolve, offering even greater precision and applications. In Mumbai, industries are increasingly adopting this technology to stay competitive.

For businesses seeking accuracy and efficiency, 3D laser scanning services are an invaluable tool. RA Global Tech in Mumbai provides comprehensive solutions tailored to diverse needs, ensuring precise data capture and high-quality models. Whether you're in construction, manufacturing, or heritage preservation, 3D laser scanning can streamline your projects and improve outcomes. Additionally, RA Global Tech offers 3D Printing Services, providing a complete package for creating accurate prototypes and final products.

© 2026 RA Global Tech Solutions

Site design and developed by Rajkar Global