In recent years, 3D Printing has emerged as a transformative force in various sectors around the globe, and India is no exception.India's 3D printing industry is gaining traction, transitioning from prototype-focused applications to end-product manufacturing, driven by reduced costs and accelerated by AI integration.

Agnikul, a Chennai based spacetech firm, made history with the world's first rocket launch powered by a single-piece 3D-printed engine. What's remarkable is that they achieved this feat in just three days, a significant reduction from the typical 10-11 months of preparation time, where manufacturing a rocket engine alone usually takes six months. This innovation greatly cut down time, effort, and costs.

India's 3D printing market is gaining momentum, with diverse applications emerging across industries. According to IMARC Group, the Indian 3D printing market, valued at $707 million in 2024, is projected to reach $4.3 billion by 2033, growing at a CAGR of 21.7%.

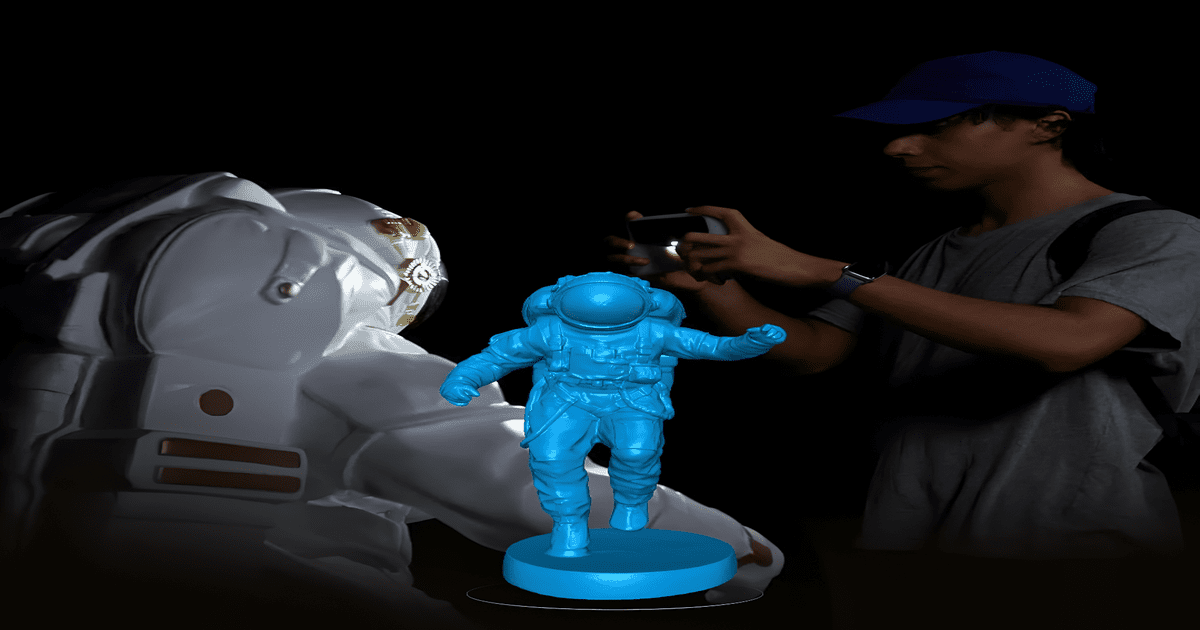

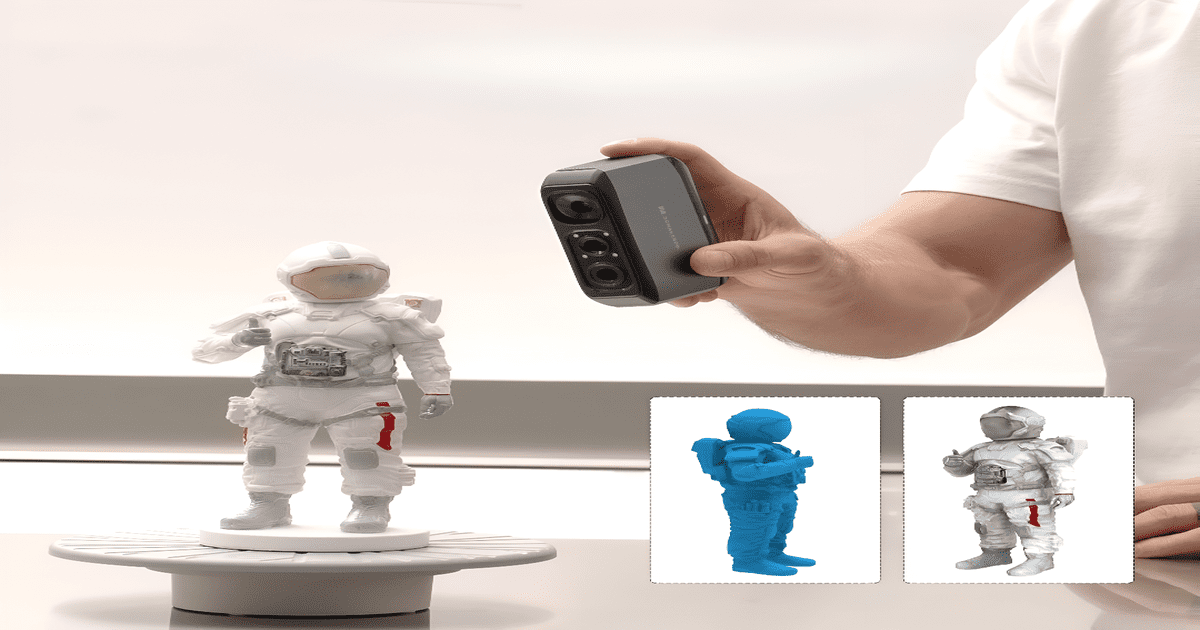

The toy industry is another area where 3D printing is making waves, allowing for designs that were previously impossible or prohibitively expensive to produce. Customizable toys that reflect the preferences of individual consumers are becoming increasingly popular, thanks to this technology. For example, parents can now design toys tailored to their children’s interests, which adds personal value to the products.

This shift toward customization is not only enhancing consumer satisfaction but also promoting a culture of creativity and innovation among young creators and entrepreneurs in India.

RA Global offers various services that can support the implementation of Rocket Fuel to Playful Tools , including

Despite the exciting developments, challenges remain. One significant hurdle is the need for skilled labor capable of operating advanced 3D printing technologies and software. Therefore, educational institutions and industry must collaborate to develop specialized training programs to build a proficient workforce.

Furthermore, regulatory frameworks need to evolve to address intellectual property issues associated with 3D printing. As the technology becomes mainstream, safeguarding innovation while fostering collaboration will be essential for sustained growth.

The 3D printing industry is shifting towards more sustainable raw materials, moving beyond traditional plastics and polymers to eco-friendly options like biodegradable corn starch. This global trend towards environmentally responsible alternatives is being actively adopted in India.

3D printing is poised to be a catalyst for India’s industrial renaissance, fundamentally changing the way products are designed and manufactured across numerous sectors. From aerospace to consumer goods, the applications of this technology are vast and varied.

As we embrace these advancements, India stands at the threshold of a manufacturing revolution—one that has the potential to stimulate economic growth, encourage entrepreneurship, and position the country as a leader in the global market. The possibilities are limitless, and as 3D printing continues to evolve, so too will the landscape of Indian industry.

© 2025 RA Global Tech Solutions

Site design and developed by Rajkar Global