Improvement in previously designed products is required to increase the usability of certain products. Some products in current use were designed with no design data stored, such as their physical or digital drawings, to refer to for making advancements in current products in use. Some products with small and complex features and internal designs are difficult to observe or measure; with no digital data on design, it becomes difficult for design upgrades. In such cases, 3D reverse engineering services are crucial for product design improvement or new product development. 3D scanning and reverse engineering are impressive processes for improvement in product design or product development and play a vital role.

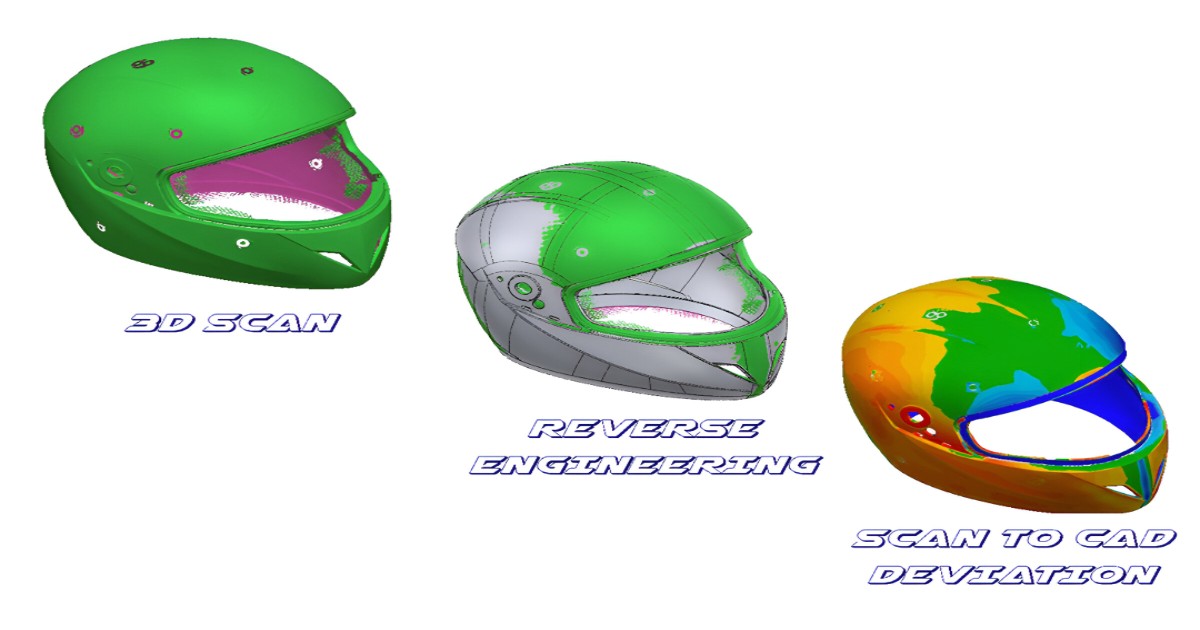

3D scanning is a process of analyzing a real-world object or an environment to collect data on its shape, color, and possibly its appearance. The collected data can then be used to construct digital 3D models.

The data obtained as the output is point cloud data, which is worked upon with various tools to obtain a solid 3D model. The 3D scanner has a somewhat characteristic feature of capturing the shape and color data of the objects.

In most cases, multiple 3D scans are required for products from different angles to collect data on their shapes from different sides, and these scans are combined to give actual point cloud data of an object, which replicates the shape of an object or makes some modifications in the product design to develop a new product out of it.

The common applications of this technology include product design or development, manufacturing, augmented reality, motion capture, gesture recognition, robotic mapping, industrial design, orthotics, and prosthetics. Reverse engineering and prototyping, quality control/inspection, and digitization of cultural artifacts are some of its other applications. These data are extensively used in the entertainment industry in the production of movies and video games, including virtual reality.

The type of scanning technique to be used depends on product size, the complexity of design, and the accuracy of output required. The accuracy of the 3D scanner for general-purpose use is 0.01mm to 0.1mm. 3D scanners can be contact types, like probe-based, or non-contact types, like portable and handheld 3D laser scanners.

The point cloud data obtained through 3D scanning is not of much use until the solid model based on the data is constructed using reverse engineering services. The STL format point cloud data is cleaned for the noise with unwanted data removed, and the data is aligned with the surface for ease of various operations to create a solid 3D model. Various textures and colors can also be captured by 3D scanning and modeled accordingly to replicate the available solid product. This technique helps in easing the measurement task on a product that is difficult due to its size or its location.

© 2026 RA Global Tech Solutions

Site design and developed by Rajkar Global