Restoring damaged or discontinued motorcycle parts is a common challenge for classic and premium bike owners. In this case study, we showcase how a damaged Triumph motorcycle component was successfully restored using modern 3D scanning, reverse engineering, and additive manufacturing technologies. By combining 3D scanning, 3D CAD modeling, FEA, 3D printing, and post-processing, a fully functional replacement part was created with high accuracy and durability.

The original Triumph motorcycle rear seat cowl was severely damaged and deemed irreparable. Conventional repair techniques were unsuitable due to the component's intricate geometry and the unavailability of original 3D CAD data or replacement parts. The primary objective was to accurately recreate the part, ensuring dimensional precision and adherence to the original functional, durability, and aesthetic specifications.

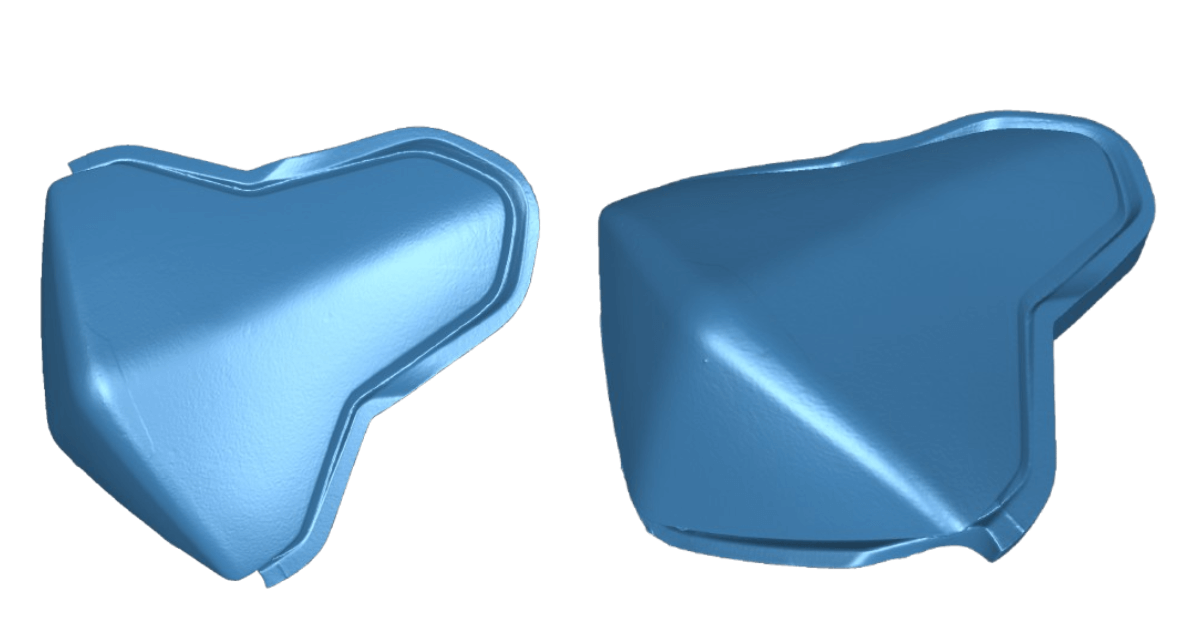

The restoration process began with high precision 3D scanning, where laser or structured light was projected onto the object and the reflection of XYZ coordinates was analysed to calculate precise geometry and create point cloud data on the surfaces of the article. Key technologies included triangulation and time-of-flight methods based on measuring light travel time to map surfaces, which were then processed to create a 3D mesh and further with reverse engineering CAE CAD tools to create best-fit Class A surfaces. That's how the damaged part was scanned to capture its exact geometry, including curves, mounting points, and fine surface details. Even with partial damage, the 3D scanner accurately recorded the usable sections of the component, generating a detailed digital 3D point cloud. This digital 3D data served as the foundation for reverse engineering, ensuring that the new design part would match the original as closely as possible without losing its functional parameters.

Using the 3D scanned data, engineers created a 3D CAD model through reverse engineering. Missing or damaged areas were digitally repaired by reconstructing surfaces and correcting geometries. Functional features such as holes, slots, and alignment points were refined to ensure proper fitment on the motorcycle. This stage allowed designers to make design improvements where needed, ensuring better strength and dimensional accuracy compared to the original part.

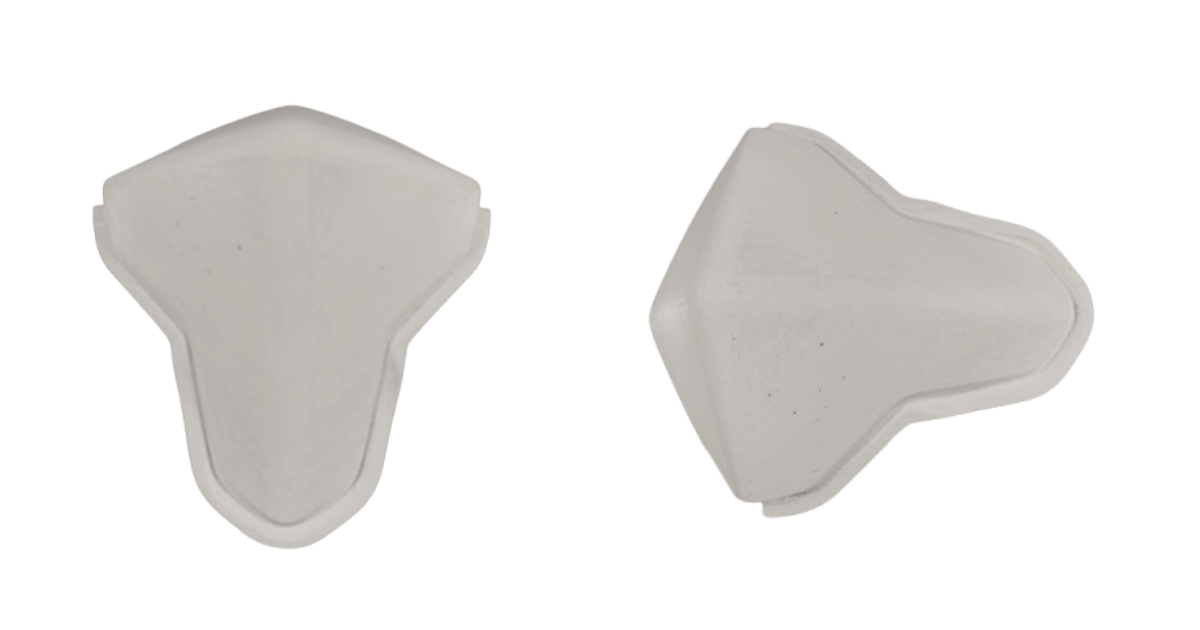

Once the 3D CAD model was finalized, the replacement part was manufactured using industrial-grade FDM 3D printing. FDM 3D printers build objects layer by layer by extruding melted thermoplastic filament, making it a popular, cost-effective method for rapid prototyping and creating custom parts, from sculpture models to industrial jigs and tools, using materials like PLA, ABS, or nylon. These machines work by unwinding filament from a spool, heating it in a nozzle, and depositing it onto a build plate, creating objects layer by layer. The selected material offered the required strength, durability, and resistance suitable for motorcycle use. Additive manufacturing enabled fast production without the need for tooling or molds, making it a cost-effective and time-efficient solution for low-volume or one-off components.

After 3D printing, the part underwent post-processing to improve surface finish. This included cleaning, sanding, and finishing to achieve the desired appearance and fit. Post-processing ensured the part met both functional requirements and visual standards expected in motorcycle restoration.

The finished component was successfully installed on the Triumph motorcycle, fitting perfectly and performing as intended. The restored part not only replaced the damaged original but also demonstrated how modern digital manufacturing technologies can extend the life of premium motorcycles.

This case study highlights the effectiveness of 3D scanning, 3D reverse engineering, design optimization using FEA, and 3D printing in restoring damaged motorcycle parts. For brands like Triumph, where precision and quality are critical, additive manufacturing offers a reliable solution for part restoration, customization, and legacy component manufacturing. By leveraging these advanced technologies, manufacturers and service providers can deliver faster turnaround times, reduced costs, and high-quality results for motorcycle restoration projects.

RA Global Tech Solutions manages the entire process under one roof, from high-accuracy 3D scanning and 3D reverse engineering to 3D printing and post-processing. This ensures better control, quality, and faster delivery. With strong engineering capabilities, we specialize in reverse engineering complex and damaged components, even when original drawings or 3D CAD files are unavailable. RA Global Tech Solutions uses advanced 3D printing technologies and engineering-grade materials to manufacture durable, functional parts suitable for real-world applications.

© 2026 RA Global Tech Solutions

Site design and developed by Rajkar Global