3D Scan to 3D CAD

What is a 3D scan to 3D CAD?

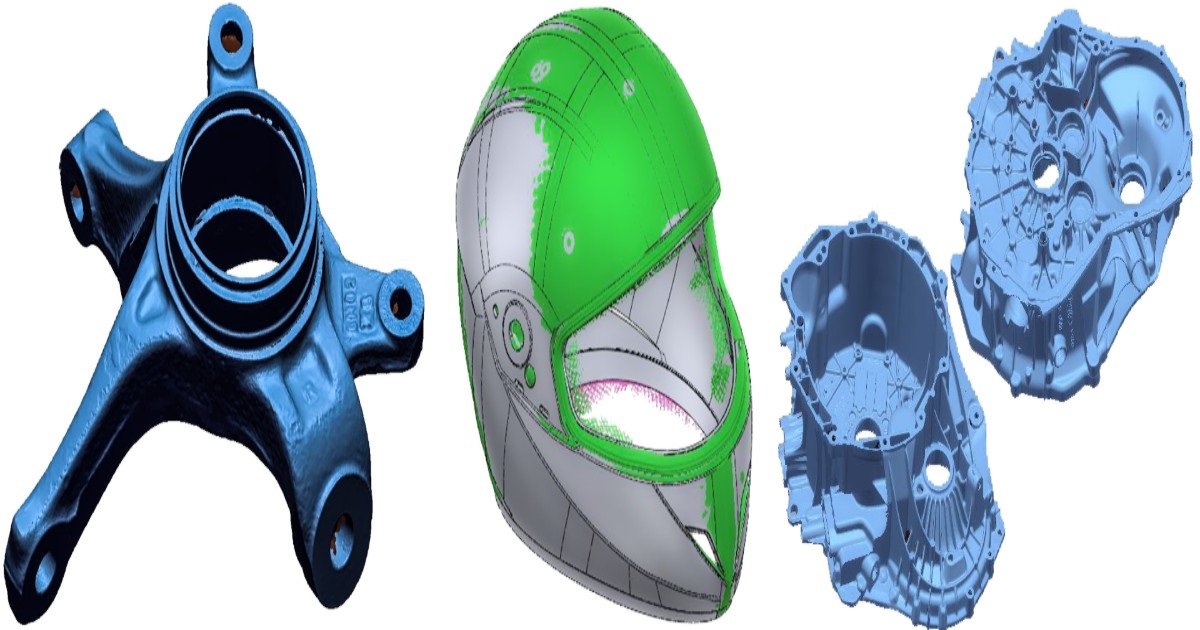

3D scan to 3D CAD is a key reverse engineering process that transforms a physical object into a precise, editable digital 3D model. Using advanced 3D scanning technology, the surface geometry of an object is captured as a point cloud, a dense collection of spatial data points representing the object's exact shape and dimensions. This point cloud data is then processed using specialized software to generate a parametric or non-parametric 3D CAD model, which can be utilized for various engineering and design applications.

3D scanning technology captures the physical dimensions and intricacies of an object, creating a detailed point cloud or mesh. 3D CAD modeling is its ability to accurately capture the physical characteristics of an object. This is particularly useful in cases where there is no existing digital model of the object or where the object is too complex or large to be measured manually. By using 3D scanning technology, designers and engineers can capture all the necessary information about an object’s shape, size, and texture, as well as any other features that are important for the design process.

Key Aspects of 3D scan to 3D CAD:

- Data Capture: 3D scanning technology captures precise physical dimensions and intricacies of objects or sites

- Point Cloud or Mesh Creation: Captured data is processed to create detailed point clouds or meshes

- 3D CAD Model Creation: Advanced software is used to convert point clouds/meshes into accurate 3D CAD models

- Accuracy and Precision: Ensures precise capture of complex geometries, shapes, and features

- Applications: Enables design refinement, engineering analysis, prototyping, production, and more

- Reverse Engineering: Useful for creating digital models from physical objects, especially when no existing digital model is available

Why is a 3D scan to 3D CAD important?

3D Scan to 3D CAD services are crucial for improving accuracy, saving time, and enhancing design. They enable precise capture of complex geometries, streamline production, and support reverse engineering. By leveraging these services, industries like manufacturing, construction, and healthcare can reduce costs, minimize errors, and drive innovation, ultimately improving efficiency and productivity.

What are the common challenges in 3D scan to 3D CAD?

Converting 3D scan data to 3D CAD models can pose several challenges, including data quality issues, complexity in scanning large or intricate objects, managing and processing large point cloud data, and converting scan data into accurate 3D CAD models. Additionally, surface reconstruction and ensuring file format compatibility between 3D scan data and 3D CAD software can also be difficult. Expertise in 3D scanning, data processing, and 3D CAD modeling is essential to overcome these challenges.

Related Services

- 3D Modeling: Creating detailed 3D models from scan data for various applications.

- Reverse Engineering: Replicating or modifying existing products using 3D scanning and 3D CAD design.

- Product Design: Designing new products or modifying existing ones using 3D scan data.

- Prototyping: Creating physical prototypes from 3D CAD models for testing and validation.

- 3D Printing: Additive manufacturing of parts and products from 3D CAD models.

- CAD Design: Creating detailed 2D and 3D CAD models for various industries.

- Scan Data Processing: Cleaning, filtering, and processing 3D scan data for 3D CAD modeling.

- Quality Inspection: Inspecting and analyzing 3D scan data for quality control and assurance.

These services complement 3D Scan to 3D CAD by providing a comprehensive solution for design, engineering, and manufacturing applications.

The Process

- Scanning: Capture the geometry of the physical object or environment using advanced 3D scanning technology. The scanner records millions of data points, creating a detailed point cloud representation of the surface.

- Data Processing: Clean, align, and merge multiple 3D scans to remove noise and prepare a unified dataset. The processed point cloud serves as the foundation for accurate 3D CAD reconstruction.

- CAD Modeling: Using specialized reverse engineering software, convert the processed scan data into a 3D CAD model, either parametric or non-parametric, depending on project requirements.

- Model Refining: Enhance and fine-tune the 3D CAD model by adding precise geometrical features, fillets, holes, and design elements to match the original part or to improve functionality.

- Quality Control: Verify the dimensional accuracy of the 3D CAD model by comparing it against the original 3D scan data. This ensures that the model meets all tolerances and quality standards.

- Final Delivery: Deliver the completed 3D CAD model in the client's preferred format for downstream applications such as design, analysis, or manufacturing.

This workflow can be customized based on the complexity of the object, the required level of detail, and the intended application, whether for product redesign, quality inspection, reverse engineering, or digital archiving.

The details of your product can be found in the dense point clouds produced by a 3D scanner or the exact measurements from a touch probe. Our reporting and analysis tools will use these 3D data to show you exactly what the as-built condition is and how much it differs from the perfect, as-designed 3D CAD model.

You can utilize the data from your 3D scanning to track changes in your manufacturing processes over the course of weeks, months, or even years of service. To track changes over time, combine the original 3D CAD design data with 3D scan data from the first article inspection and 3D scan data from the most current production run. Color maps and in-depth, tabular data will both be included in your statistical process report.

What are the applications of 3D scans to 3D CAD across various industries?

- Aerospace and Defense: Reverse-engineer legacy parts, create digital twins, and optimize designs for lightweight and efficient aircraft and defense systems.

- Automotive: 3D scan and recreate complex geometries, such as engine components, interior trim, and exterior body panels, to improve design accuracy and reduce prototyping costs.

- Architecture, Engineering, and Construction (AEC): Create accurate 3D models of buildings, bridges, and infrastructure projects from 3D scan data, enabling better design, construction, and maintenance planning.

- Product Design and Manufacturing: Reverse-engineer competitor products, create digital models of existing products, and optimize designs for improved performance, reduced material waste, and faster time-to-market.

- Healthcare and Medical Devices: Create accurate 3D models of patient anatomy, implants, and medical devices, enabling better diagnosis, treatment planning, and device design.

- Heritage Preservation and Restoration: Create detailed 3D models of historical artifacts, buildings, and monuments, enabling preservation, restoration, and virtual recreation.

- Industrial Equipment and Machinery: Reverse-engineer legacy equipment, create digital twins, and optimize designs for improved performance, reduced energy consumption, and extended lifespan.

Why Choose RA Global?

At RA Global Tech Solutions, we combine technical expertise, advanced technology, and industry experience to deliver precise, reliable, and high-quality engineering solutions.

- Expertise: Our team of experienced professionals delivers high-quality services, leveraging industry-leading technologies and expertise in capturing data for various applications.

- Advanced Technology: RA Global utilizes cutting-edge software and equipment, ensuring accurate and efficient results in 3D scanning, 3D CAD modeling, and reverse engineering.

- Customized Solutions: We offer tailored services to meet specific client needs and requirements, providing personalized support and solutions.

- Quality Assurance: RA Global's rigorous quality control processes guarantee precise and reliable outcomes, ensuring clients receive accurate digital models and designs.

RA Global stands out with its innovative approach, staying current with industry trends and best practices to bring cutting-edge solutions to clients' projects. They offer competitive pricing without compromising on quality, making their services an attractive option for businesses.

Local 3D Scanning, Scan to 3D CAD Services in India. Contact Us

Frequently Asked Questions

What is a 3D scan to 3D CAD?

It converts high‑resolution 3D scans of physical parts into accurate, editable CAD models for design, analysis, or manufacturing purposes.

Why use RA Global for 3D scan to 3D CAD?

We combine precise laser scanning with expert 3D CAD modeling to deliver reliable, high‑quality digital files tailored to your specific project requirements.

Which industries benefit from 3D scan to 3D CAD?

Automotive, aerospace, industrial machinery, product design, and heritage restoration often use 3D scans to 3D CAD for reverse engineering and quality control.

Can you handle complex or freeform surfaces?

Yes! Our advanced scanning equipment and modeling tools capture and recreate intricate geometries, curves, and detailed freeform surfaces accurately.

What file formats do you provide?

We deliver 3D CAD files in formats like STEP, IGES, STL, and native formats compatible with popular design and engineering software.