DMLS 3D Printing: Direct Metal Laser Sintering

In a world driven by innovation and technological advancements, the manufacturing industry has witnessed a remarkable transformation with the emergence of 3D printing technologies. One such groundbreaking technique is Direct Metal Laser Sintering, a form of 3D printing that has revolutionized the way we approach complex and precision manufacturing. RA-Global, a pioneer in the field, offers cutting-edge qualitative DMLS 3D printing that is reshaping industries and pushing the boundaries of what is possible.

Direct Metal Laser Sintering is a metal additive manufacturing technology that uses a high-powered laser to melt powdered metal, layer by layer, to create a three-dimensional object. DMLS is a highly versatile technology that can be used to create complex metal parts with high accuracy and precision.

What is direct metal laser sintering (DMLS)?

Direct Metal Laser Sintering (DMLS), also known as Selective Laser Melting (SLM), is a precise 3D printing technique that uses a laser to fuse metal powders into complex parts. Guided by a CAD file, the laser selectively melts the powder, layer by layer, to create accurate parts with excellent surface quality and mechanical properties.

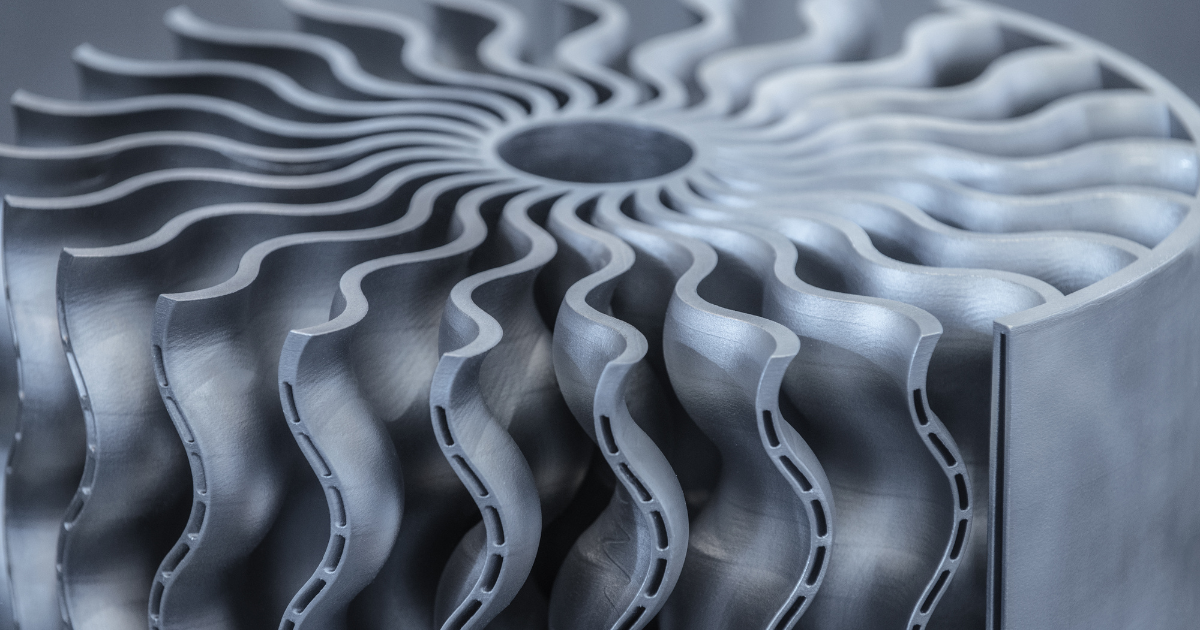

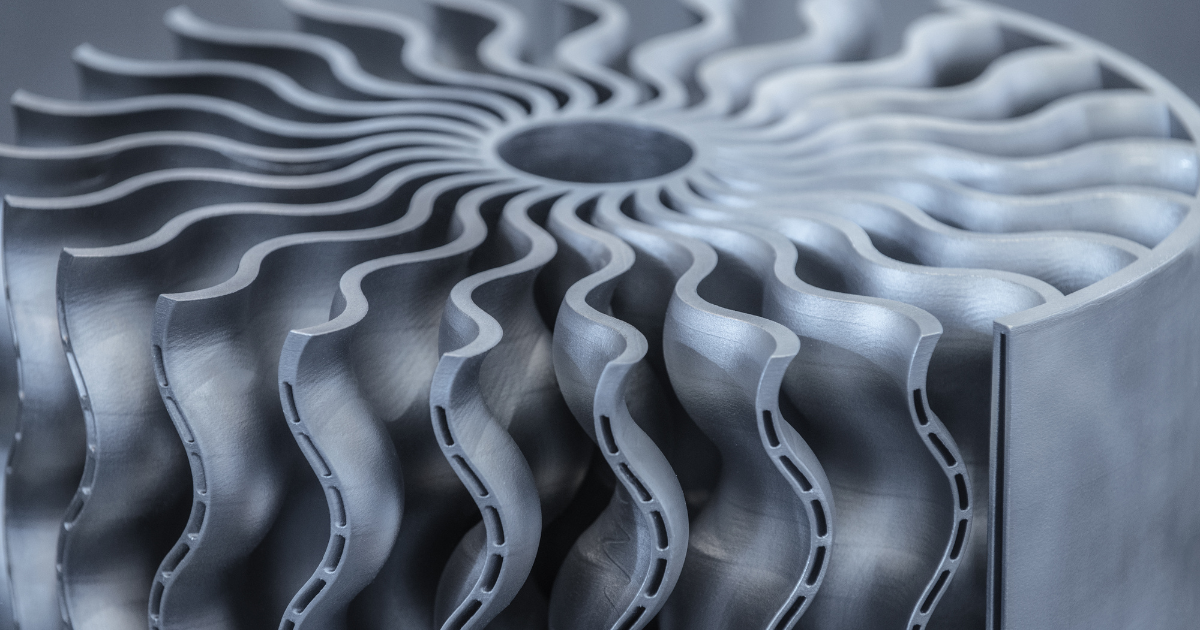

DMLS is ideal for producing complex geometries, such as parts with hollow spaces, undercuts, and challenging angles, making it perfect for low-volume production and customized parts. With DMLS, you can avoid the time and expense of creating tooling, and parts can be stored digitally and printed on demand, reducing inventory costs and increasing design flexibility.

The benefits of DMLS include high accuracy, excellent surface quality, and near-wrought mechanical properties, making it suitable for producing parts that require precise control and durability. Overall, DMLS offers a versatile and efficient solution for producing complex metal parts with high precision and accuracy.

Key aspects of DMLS 3D printing:

- Metal Additive Manufacturing Technology: DMLS (Direct Metal Laser Sintering) uses a high-powered laser to fuse fine metal powder layer by layer, creating fully functional metal parts with exceptional precision.

- High Strength & Durability: Parts produced through DMLS exhibit mechanical properties comparable to traditionally manufactured metal components, making them suitable for demanding industrial applications.

- Complex Geometry Capability: DMLS enables the creation of intricate internal structures, lightweight lattice designs, and complex geometries that are difficult or impossible to achieve with CNC machining or casting.

- Wide Range of Metal Materials: Supports various metal powders such as stainless steel, aluminum, titanium, Inconel, cobalt-chrome, and tool steel, each offering unique advantages for specific industries.

How does DMLS 3D printing work?

DMLS 3D printing works by first creating a 3D CAD model of the desired part. This model is then sliced into several layers by slicing software, and then this data is transferred to the DMLS 3D printer. A high-powered laser then melts the powdered metal on the build platform in the desired pattern, creating a solid metal.

- Design: A CAD (Computer-Aided Design) file is created, defining the part's geometry and structure.

- Powder Preparation: A metal powder is prepared, consisting of fine particles with specific properties.

- Layer Formation: A thin layer of powder is spread evenly over the build platform.

- Laser Sintering: A high-powered laser selectively fuses the powder particles, tracing the part's geometry.

- Layer Buildup: The build platform lowers, and a new layer of powder is spread. The laser sinters the next layer, bonding it to the previous one.

- Repeat: Steps 4 and 5 are repeated, gradually building the part layer by layer.

- Post-Processing: The finished part is removed from the build platform, and any support structures are removed. Additional processing, such as machining or surface finishing, may be applied.

Types of Materials Used in DMLS 3D printing

- Stainless Steel: Strong, corrosion-resistant, and versatile. Ideal for industrial parts, tooling, and functional prototypes.

- Aluminum: Lightweight and excellent thermal conductivity. Used for aerospace, automotive, and lightweight structural components.

- Titanium: High strength-to-weight ratio and biocompatible. Commonly used in aerospace, medical implants, and high-performance engineering parts.

- Nickel Alloys (e.g., Inconel): Excellent heat and corrosion resistance. Suitable for turbine blades, engines, and high-temperature applications.

DMLS 3D printing Capabilities

- Maximum Build Size: 250 x 250 x 325 mm

- Standard Lead Time: 3–5 Business Days

- Dimensional Accuracy: ±0.1% to ±0.2%

- Layer Thickness: 20–60 μm

- Infill/Density: 100%

Design guidelines for DMLS 3D printing

- Complex Geometries: Metal 3D printing excels at producing complex geometries and intricate designs

- Wall Thickness: Minimum wall thickness of 0.5-1 mm is recommended to ensure structural integrity

- Feature Size: Minimum feature size of 0.5-1 mm is recommended to ensure accuracy and detail

- Radius and Fillets: Adding radii and fillets can improve part strength and reduce stress concentrations

- Draft Angle: A draft angle of 1-2° is recommended to facilitate part removal from the build platform

Benefits of DMLS 3D printing

There are many benefits of using DMLS 3D printing, including:

- Complex Geometries: DMLS can be used to create complex metal parts with features that would be difficult or impossible to manufacture using traditional manufacturing methods.

- High Accuracy and Precision: DMLS parts can be produced with very high accuracy and precision, meeting even the most demanding specifications.

- Repeatability: DMLS parts are repeatable, meaning that each part produced will be identical to the previous part.

- Material Flexibility: There are many kinds of metal powders that can be used in DMLS metal 3D printing, such as steel, titanium, cobalt chrome, and aluminum.

- Shorter Lead Time: DMLS parts can be produced in short lead times, making it a good choice for prototyping and production applications.

Applications of DMLS 3D printing

- Aerospace: DMLS is widely used in the aerospace industry because it allows manufacturers to create highly complex, lightweight, and durable metal parts that must withstand extreme conditions. Components such as turbine blades, engine brackets, fuel nozzles, airframe parts, and structural supports benefit greatly from the precision and performance of DMLS.

- Automotive: In the automotive sector, DMLS is used for both rapid prototyping and the production of functional, end-use parts. Engineers can design intricate components like engine housings, brackets, heat exchangers, and performance parts without the limitations of traditional manufacturing.

- Tooling: DMLS is an excellent solution for creating high-strength molds, dies, inserts, and specialized tooling used in casting, forging, and injection molding. Because DMLS can produce conformal cooling channels and complex internal geometries, it significantly improves heat dissipation and production efficiency. This results in shorter cycle times, better product quality, and longer tool life. DMLS tooling is especially valuable for small- to medium-batch production where traditional tooling would be too costly or time-consuming.

- Jewelry: The jewelry industry uses DMLS to produce highly detailed and custom-designed pieces with exceptional precision. Designers can create intricate patterns, fine textures, and unique structures that would be extremely difficult or labor-intensive to craft by hand.

- Other: DMLS is used in a variety of other industries, such as robotics, energy, and consumer products.

At RA Global, we are harnessing the power of DMLS 3D printing to drive innovation and efficiency in various industries. Our team of experts works closely with clients to design and develop customized solutions, leveraging the benefits of DMLS 3D printing to reduce costs, increase productivity, and improve product quality. DMLS 3D printing is transforming the manufacturing landscape, offering unparalleled design flexibility, cost-effectiveness, and speed. At RA Global, we are committed to staying at the forefront of this technology, delivering innovative solutions that drive business growth and success. Whether you are looking to prototype, produce, or innovate, our team is here to help you harness the power of DMLS 3D printing.

UPLOAD your design for an Instant Quote (Acceptable file types are .stl, .step, and .x_T.)

Frequently Asked Questions

What is DMLS 3D printing?

DMLS is an additive manufacturing process that uses a high-power laser to selectively fuse fine metallic powder particles together, layer by layer.

What materials can be used in DMLS?

DMLS can process a range of high-performance metals including stainless steel, titanium, aluminum, cobalt-chrome, and nickel alloys. This allows for the production of strong, functional parts.

What are the main benefits of using DMLS?

DMLS produces parts with properties similar to wrought or cast metals, offering high strength, excellent heat resistance, and complex geometries that are impossible with traditional manufacturing.

Is DMLS suitable for end-use parts?

Absolutely. DMLS is used extensively in critical, high-value industries like aerospace and medical for producing lightweight, complex components such as turbine blades, satellite brackets, and custom implants.

What is the typical accuracy of DMLS parts?

DMLS offers very high accuracy, typically within a tolerance of $\pm0.1$ to $\pm0.2$ mm, depending on the material and part size. Parts often require post-processing (e.g., machining or polishing) for final surface finish.