Blue Light 3D Scanning

What Is Blue Light 3D Scanning?

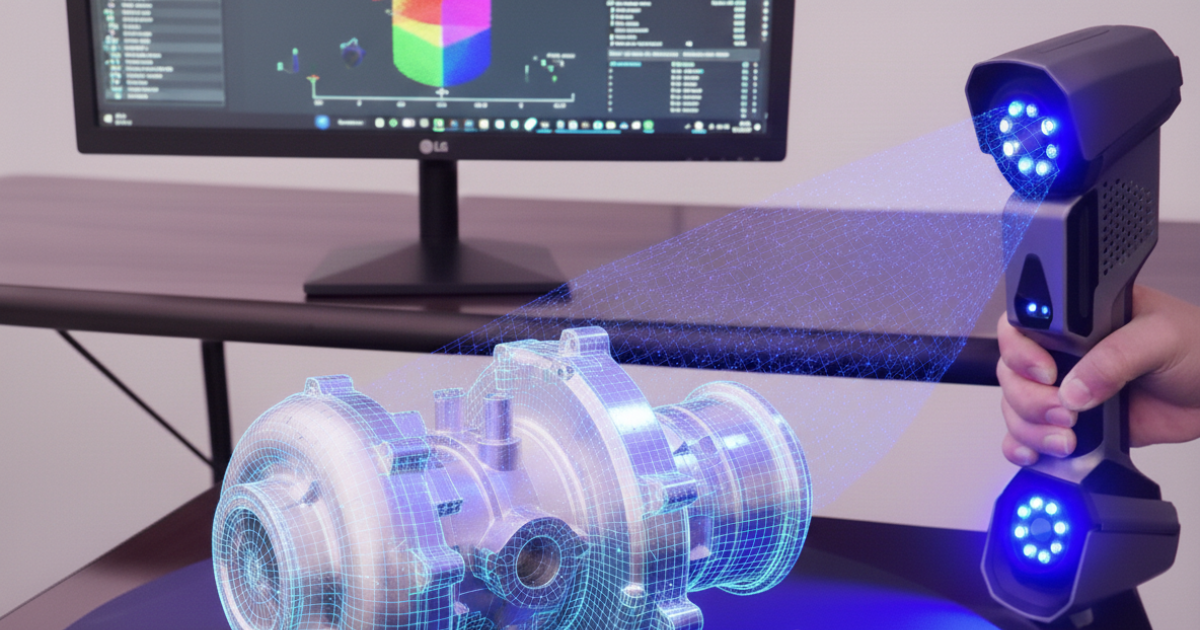

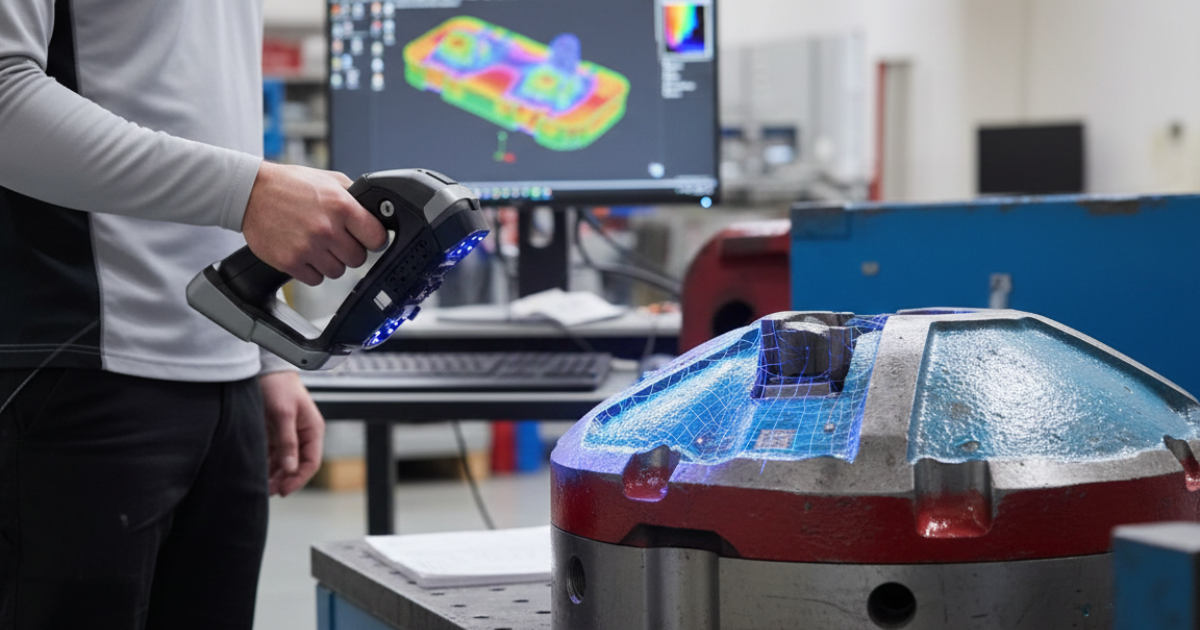

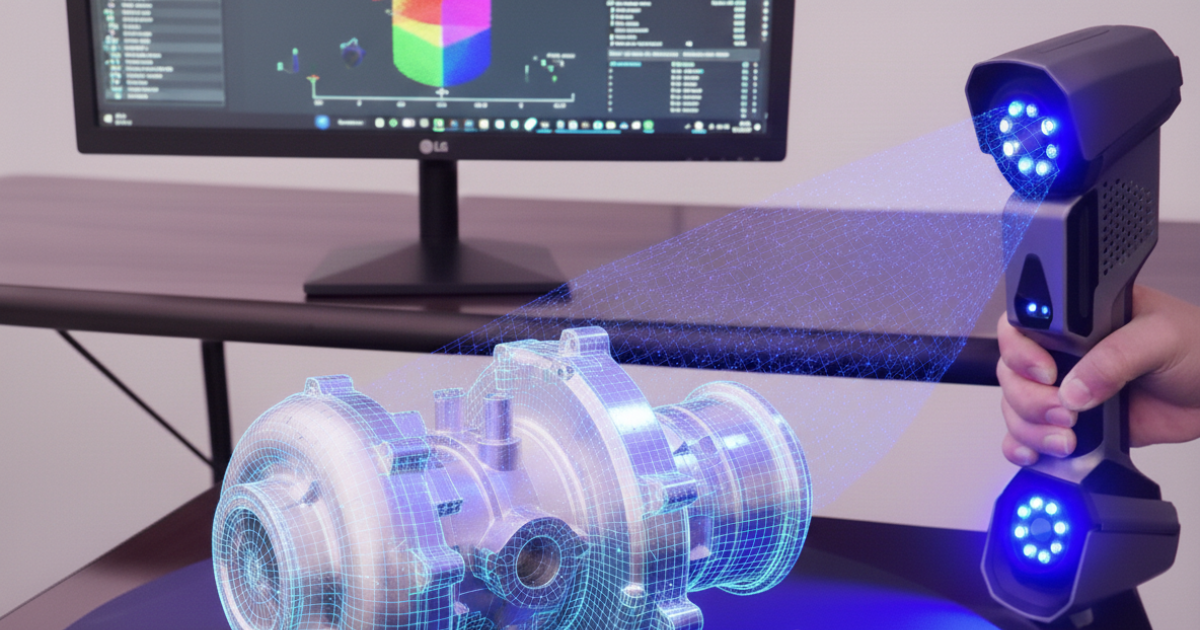

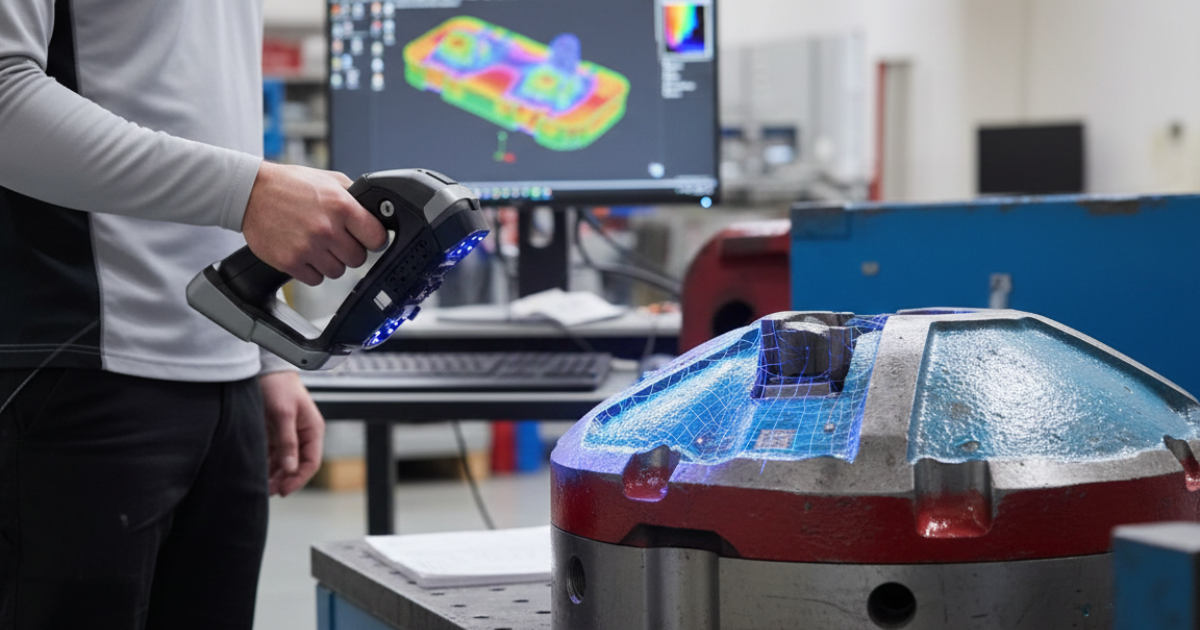

Blue Light 3D Scanning is a high-precision, non-contact optical measurement technology used to capture the exact geometry of physical objects with exceptional accuracy. It uses narrow-wavelength blue LED light instead of white light to project structured patterns onto an object’s surface. High-resolution cameras record how these patterns deform, and specialized software analyzes this deformation to generate highly accurate 3D data.

The use of short-wavelength blue light minimizes the effects of ambient lighting and surface reflections, allowing the scanner to excel at capturing complex geometries, fine details, and challenging surfaces such as dark, shiny, or reflective materials. The captured data is processed into dense point clouds or polygon meshes, which can be further converted into CAD-ready 3D models.

At RA Global, Blue Light 3D Scanning supports critical applications including quality control, dimensional inspection, reverse engineering, and design validation, delivering reliable, high-accuracy results across a wide range of industrial applications.

Key Aspects of Blue Light 3D Scanning

- High Accuracy and Resolution: Blue Light 3D Scanning delivers exceptionally high accuracy by using short-wavelength blue light and advanced triangulation principles. The shorter wavelength reduces noise and increases measurement precision, allowing the system to capture fine surface details, sharp edges, and tight dimensional tolerances.

- Non-Contact Measurement: As a fully non-contact optical scanning technology, Blue Light 3D Scanning does not physically touch the component during measurement. This eliminates the risk of deformation, wear, or damage, particularly when scanning delicate parts, thin-walled components, soft materials, or finished surfaces.

- Fast Data Acquisition: Blue Light 3D scanners capture millions of data points in a single scan, enabling rapid digitization of complex geometries. Unlike traditional point-by-point measurement methods, structured light scanning records large surface areas simultaneously, significantly reducing inspection time.

- Excellent Surface Adaptability: The use of blue light minimizes the influence of ambient lighting and reduces issues caused by surface reflections. As a result, Blue Light 3D Scanning performs exceptionally well on dark, shiny, reflective, and highly detailed surfaces.

- Full-Field Measurement: Unlike contact probes or laser scanners that measure one point or line at a time, Blue Light 3D Scanning provides full-field measurement, capturing entire surfaces in each scan. This allows for comprehensive geometry analysis, complete surface comparison, and the detection of form deviations that might be missed by discrete measurement techniques.

- Digital Output: The scanned data is converted into dense point clouds or polygon meshes, which are fully compatible with inspection and 3D CAD software. These digital outputs can be used for 3D comparison, deviation analysis, CAD reconstruction, reverse engineering, and reporting.

Why Is Blue Light 3D Scanning Important?

Blue Light 3D Scanning is important because it enables fast, highly accurate, and non-contact measurement of complex components, helping manufacturers reduce development time, improve product accuracy, and prevent costly errors before production. By capturing complete surface geometry and identifying even minor deviations at early stages, it supports precise design validation, quality control, and reverse engineering. This early detection of issues minimizes rework and material waste, improves process efficiency, and ensures components meet tight tolerances, ultimately allowing businesses to achieve better quality, higher reliability, and faster time-to-market in modern manufacturing environments.

Common Challenges in Blue Light 3D Scanning

Common challenges in Blue Light 3D Scanning mainly arise from surface properties, geometry complexity, data volume, and environmental factors. Highly glossy, reflective, or transparent surfaces can scatter or distort projected light, often requiring surface preparation such as matte sprays to ensure accurate data capture. Components with complex geometries, such as deep cavities, undercuts, and sharp edges, demand well-planned scanning strategies, multiple scan angles, and operator expertise to avoid shadowing and data gaps. The high-resolution nature of blue light scanning generates large datasets, which can increase data processing time and require skilled handling for alignment, noise reduction, and optimization. Additionally, environmental conditions such as vibrations, unstable mounting, or inconsistent lighting can impact measurement accuracy, making a controlled setup and proper fixturing essential for reliable results.

Related Services

- Reverse Engineering Services: Converting blue light scan data into accurate, CAD-ready models for part replication, design modification, and legacy component reconstruction.

- 3D CAD Modeling and 3D Design: Creating precise, manufacturable 3D CAD models from point clouds and meshes to support design optimization and engineering workflows.

- Dimensional Inspection and Quality Control: Performing full-field inspection, GD&T analysis, and deviation reporting to ensure components meet design specifications and quality standards.

- Product Development Support: Supporting the entire development cycle, from concept validation and prototype evaluation to design refinement and pre-production analysis.

- Rapid Prototyping and 3D Printing: Producing functional and visual prototypes quickly using additive manufacturing to validate form, fit, and function while reducing time-to-market.

The Blue Light 3D Scanning Process

- Requirement Analysis: Understanding the project objectives, component complexity, tolerance levels, and accuracy requirements to define the most effective scanning strategy.

- Part Preparation: Cleaning the component and applying surface treatment or matte coating if required to ensure optimal data capture on reflective, dark, or transparent surfaces.

- Scanning Execution: Projecting structured blue light patterns onto the part and capturing high-resolution data from multiple angles to record complete surface geometry.

- Data Processing: Aligning multiple scans, filtering noise, and optimizing the dataset to create accurate and consistent point clouds or mesh data.

- 3D Model Generation: Converting processed scan data into polygon meshes or CAD-ready 3D models suitable for inspection, reverse engineering, or design workflows.

- Validation and Delivery: Verifying dimensional accuracy against project requirements and delivering final inspection-ready or CAD-compatible outputs to the client.

Applications of Blue Light 3D Scanning Across Industries

Blue Light 3D scanning is a non-contact, high-precision measurement technology that captures accurate 3D data of physical objects. Its speed, resolution, and reliability make it indispensable for a wide range of industries, enabling everything from quality control to reverse engineering and digital preservation.

- Automotive: In the automotive sector, Blue Light 3D scanning is used for part inspection, assembly verification, and tool validation. It allows engineers to measure components with micrometer-level accuracy, compare manufactured parts against CAD models, and detect deviations before assembly. Additionally, it supports reverse engineering of legacy parts, helping manufacturers reproduce or upgrade components for which original CAD data is unavailable.

- Aerospace: Aerospace components are often complex, lightweight, and safety-critical. Blue Light 3D scanning enables precision inspection of turbine blades, structural brackets, housings, and assemblies, ensuring compliance with strict dimensional tolerances. The technology facilitates quality assurance, reverse engineering, and maintenance checks, supporting both production and in-service lifecycle requirements.

- Manufacturing: In general manufacturing, blue light 3D scanning plays a key role in quality control and dimensional analysis. It allows rapid inspection of parts and assemblies to detect defects, warping, or deviations from design specifications. Manufacturers use scanning for first article inspections, in-line quality monitoring, and tolerance verification, ensuring products meet rigorous standards before delivery.

- Medical Devices: Medical devices and implants often require customization for individual patients. Blue Light 3D scanning captures precise anatomical geometry, enabling engineers to create custom-fit prosthetics, surgical guides, and implants. High-resolution 3D models ensure that components conform perfectly to patient anatomy, improving safety, comfort, and functionality.

- Consumer Products: For consumer goods, blue light 3D scanning helps in design validation, product improvement, and prototype evaluation. It allows designers to measure, compare, and refine parts, ensuring ergonomic and aesthetic requirements are met. Rapid scanning accelerates the development cycle by providing accurate feedback for iterative design improvements.

- Heritage and Art: Blue light 3D scanning is also used in the digital preservation and replication of heritage objects, sculptures, and artifacts. By capturing precise surface details and geometry, the technology enables documentation, restoration, reproduction, and archiving of valuable cultural assets without damaging the original objects.

Why Choose RA Global?

RA Global Tech Solutions LLP is a trusted blue light 3D scanning service provider in India and across the globe, delivering precision-driven solutions for a wide range of industries. We combine industry-grade blue light 3D scanning systems with highly skilled engineering and inspection teams to produce accurate, reliable, and repeatable results that support smarter design, engineering, and manufacturing decisions. With proven expertise across multiple sectors, RA Global offers end-to-end capabilities, from high-accuracy scanning and CAD modeling to dimensional inspection and validation. Our strong commitment to quality, data confidentiality, and timely project delivery ensures every engagement is executed with technical excellence and professionalism.

Frequently Asked Questions

How accurate is Blue Light 3D Scanning?

Blue Light 3D Scanning offers very high accuracy, often within microns, depending on part size and system configuration.

Can reflective parts be scanned?

Yes with proper surface treatment and optimized scanning techniques.

Is Blue Light 3D Scanning suitable for reverse engineering?

Absolutely. It is widely used to create precise CAD models from physical parts.

What file formats are delivered?

Common outputs include STL, OBJ, and CAD-compatible formats.

Does RA Global provide on-site scanning services?

Yes, RA Global offers both on-site and in-house Blue Light 3D Scanning solutions based on project requirements.