Additive manufacturing (AM) was invented in the mid-1980s in Japan, after which it soon became well-known for rapid prototyping all over the world. Additive manufacturing, also known as 3D printing, is a technology that builds objects by adding material layer by layer. Materials used in this method can range from plastics, metals, ceramics, and cement, amongst many others. Today, it is being utilized in several industries: aerospace, healthcare, automotive, construction, and manufacturing to produce final product parts. This method has become more tangible in recent years and is the future for engineers and the manufacturing industry.

Bringing additive manufacturing into mainstream bulk manufacturing will shockingly reduce production costs while simultaneously improving the quality of the product. Unlike traditional methods of manufacturing, additive manufacturing does not require the building of molds or any special machinery; a single Computer-Aided Design software file is the only pre-production element necessary.

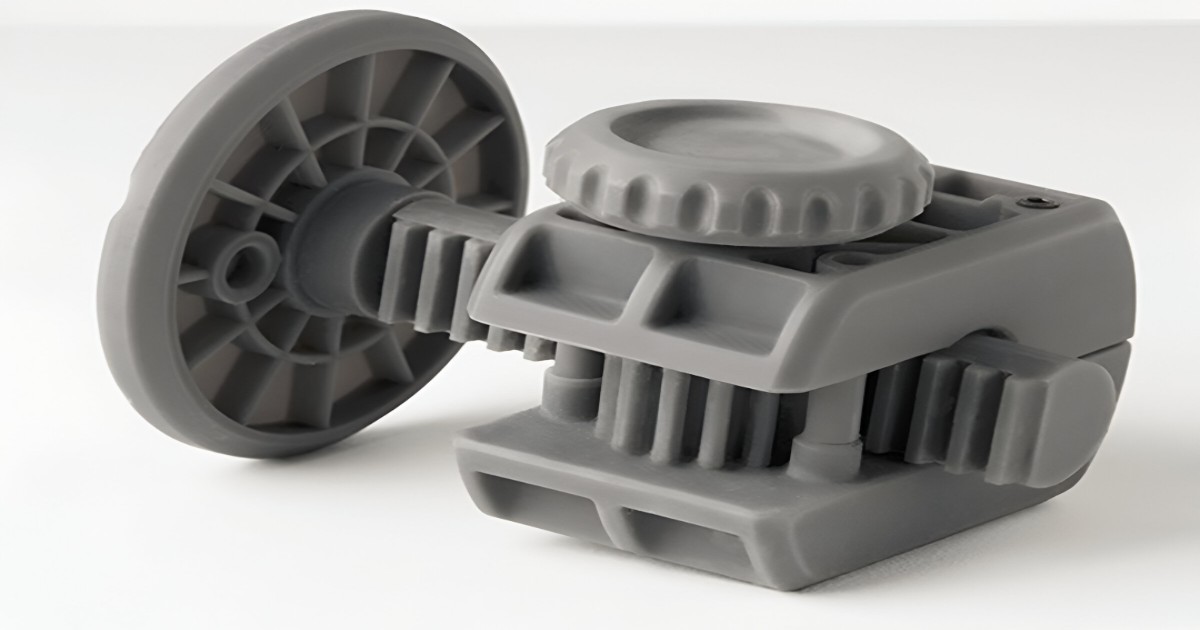

A single additive manufacturing machine is capable of working with different materials to produce a vast array of products, hence reducing investment costs greatly. Labor costs are relatively low, as there is no requirement for assembling, as the product is made as a single part. The quality of the product is much superior, as materials such as carbon fibers and titanium can be integrated easily into the product. The entire process of making a finished product has no human interference, hence eliminating the possibility of any human error that may occur during a traditional manufacturing process and also increasing the rate of production by several folds.

Traditionally, a manufacturer's production ability would decide the structural design of the product. But with the introduction of 3D printing services, the power is in the hands of engineers, and they have total liberty to design as they envision the product. Customization of products based on the customers' needs at lower costs is a much more plausible concept with 3D printing. Professionals in the healthcare industry are looking to create replacement parts and bones specific to their patients' needs for a higher success rate and reduced infections. This technology is also proving to be a game-changer for the aerospace industry, as lighter but more durable parts can be made. In space astronauts and engineers use 3D printing to print crucial parts in case of emergencies. Another impeccable feature of additive manufacturing technology is that modifications and adjustments to the product design can be made at any moment without increasing costs or slowing down the production process.

The environment also benefits greatly from this process. Due to the lack of raw materials needed to mold or color the product, there is a significant drop in the waste generated. Often machines also release toxic waste while producing products, which is then released into freshwater bodies and oceans, causing water pollution. Some products made by traditional machines also require burring and heating, which release toxins into the air. With the use of 3D printing, no materials are wasted and no form of pollution is caused.

There are several challenges to the scaling of 3D printing to become the new ordinary form of production. There needs to be more research and development done in this area to improve upon materials and efficiency and reduce initial setup costs. Engineers need to be more open to experimenting and educating themselves about additive manufacturing, and countries need to improve their digital framework to ensure the success of this promising method. Several hurdles stand in the way of the success of this manufacturing method, but it is capable of being the next industrial revolution that will benefit consumers, business owners, and the environment alike.

© 2026 RA Global Tech Solutions

Site design and developed by Rajkar Global