In the fast-paced world of technology, innovation and vision are the driving forces behind successful companies. RA Global Tech is one such company that has turned its vision into reality, providing cutting-edge technology solutions to businesses worldwide. Let us take a closer look at the story of RA Global Tech Solutions LLP and how it has evolved from an idea to a thriving technology company.

In 2017, RA Global Tech Solutions embarked on a remarkable journey, fueled by a vision to bridge the gap between technology and innovation. From a small office space with just one PC, the company has grown into a trusted partner for businesses across various industries.

With a team of passionate and experienced engineering professionals, RA Global began its quest to deliver tailored solutions that meet the unique needs of its clients. From concept to commissioning, the team ensured seamless execution and exceptional quality, laying the foundation for long-term partnerships with clients.

As the company grew, so did its expertise. The RA Global team expanded, and its capabilities evolved to include

Through its journey, RA Global has remained committed to delivering value to its clients. By fostering strong partnerships and providing exceptional solutions, the company has established itself as a leader in the engineering services industry.

By partnering with RA Global, businesses can unlock the potential of trusted engineering solutions and services, transforming ideas into tangible successes.

Driven by a relentless pursuit of engineering excellence, RA Global Tech Solutions operates as a trusted partner to some of the world's most influential brands across multiple industries, including automotive, aerospace and defense, medtech and healthcare, energy, and more. At the heart of RA Global's approach is a conviction that true engineering transformation comes from partnership. Rather than offering transactional support, the company embeds engineering teams inside client ecosystems through what it calls Virtual Business Units (VBUs). These dedicated teams are empowered to make decisions at speed, collaborate across time zones, and co-create custom solutions at the source of the client need. Whether designing innovative product solutions, optimizing complex systems, or building predictive models, RA Global delivers full lifecycle engineering solutions. With expertise spanning various domains, RA Global is committed to driving engineering excellence and delivering value to its clients. By partnering with RA Global, businesses can unlock the potential of trusted manufacturing solutions and services, transforming ideas into tangible successes.

Our journey began with a vision to bridge the gap between technology and innovation. We have worked tirelessly to make that vision a reality, delivering high-end engineering services that drive innovation and growth. With a team of experienced engineers and experts, we have provided tailored solutions that meet the unique needs of our clients. Our mission is to empower businesses with cutting-edge engineering solutions that enhance their competitiveness, efficiency, and sustainability. We strive to deliver exceptional value to our clients, partners, and stakeholders through our expertise, creativity, and commitment to excellence. At RA Global Tech Solutions, we are dedicated to delivering innovative engineering solutions that drive growth and excellence. With our expertise, commitment to quality, and customer-centric approach, we are confident that we can help businesses achieve their goals.

A lights-out factory, often referred to as a dark factory, runs with little to no human presence, enabling it to operate autonomously without on-site human intervention, essentially functioning in the dark. As industries look towards the "factory of the future," autonomous manufacturing in these settings is anticipated to expand across various sectors.

Dark factories, also known as "lights-out factories," are revolutionizing the manufacturing industry with cutting-edge automation technologies. These facilities operate without human intervention, leveraging AI-driven robotics, IoT networks, and intelligent automation protocols to ensure seamless 24/7 operation with minimal energy consumption.

India is moving towards dark factories, but challenges remain. The country's manufacturing sector is expected to embrace partial dark factory operations within the next 7-10 years, with fully autonomous, AI-powered factories likely emerging in 15-20 years. Key sectors that will drive this transformation include semiconductors, AI-driven technologies, automation, IoT, and robotics.

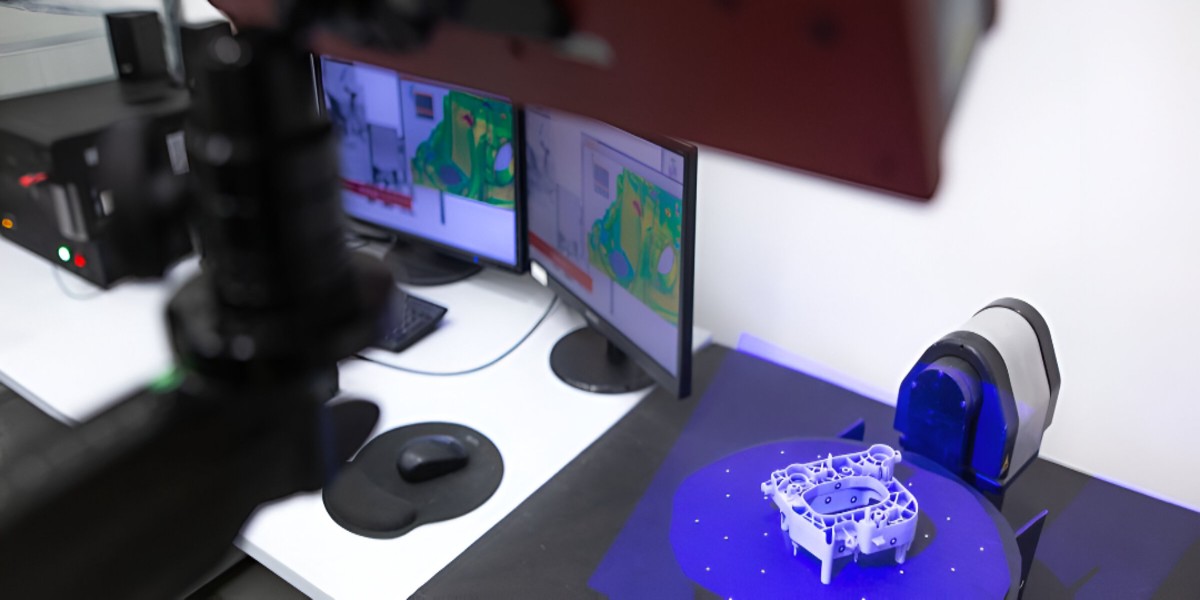

3D Scanning and Reverse Engineering: For precise geometrical digital models for automated production lines. Component Recreation: Reverse engineering uses 3D scan data to recreate digital models of physical parts for manufacturing.

Applications in Dark Factories

Product Design and Development: Creating innovative products with optimized performance and reduced costs.

In dark factories (lights-out factories), product design and development leverage advanced technologies to enable autonomous manufacturing and optimization.

Key Aspects

Technologies Enabling Dark Factory Product Development

Long-Range 3D Scanning and As-Built Documentation:

Technologies Involved-

By leveraging these services and technologies, India can navigate the transition to smart manufacturing and capitalize on the benefits of dark factory automation.

As India moves towards embracing dark factory technologies, it's clear that this revolution in automated manufacturing will bring about significant changes. With benefits like increased efficiency, cost savings, and improved safety, dark factories are poised to transform the manufacturing landscape. RA Global's services, including 3D scanning, CAD design, product development, and database architecture, can help Indian companies navigate this transition and thrive in the era of smart manufacturing. By leveraging these technologies and services, India can capitalize on the benefits of dark factory automation and emerge as a leader in the global manufacturing sector.

Source: google.com

In an era where precision drives innovation, industries are continually seeking technologies that enable accuracy, efficiency, and cost-effectiveness. One such groundbreaking advancement is 3D laser scanning, which has rapidly gained traction across multiple sectors. The growing demand for meticulous detailing in design, construction, and manufacturing has positioned 3D laser scanning service Pune as a go-to solution for engineers, architects, manufacturers, and urban developers. This technology not only captures real-world data with incredible accuracy but also transforms it into detailed, digital 3D models, paving the way for smarter decisions and faster project execution.

3D laser scanning is a high-precision technology that utilizes laser beams to measure and map the physical dimensions of objects and environments. It works by emitting lasers that bounce off surfaces and return to the scanner, calculating distances based on time and angle. The result is a dense collection of data points, known as a point cloud, which forms a comprehensive digital replica of the scanned object or space.

These point clouds are processed using advanced software to generate accurate 3D models that can be used in applications ranging from architectural design to industrial quality control. With businesses in Pune increasingly seeking high-precision solutions, the popularity of 3D laser scanning service in Pune is growing at a remarkable pace.

Adopting 3D laser scanning comes with a host of advantages that directly improve operational workflows and enhance project outcomes. Here are some of the key benefits:

Understanding the process behind 3D laser scanning service Pune provides insight into its effectiveness:

For businesses in Pune looking for reliable and efficient 3D laser scanning, RA Global Tech stands out as a trusted provider. Known for their commitment to quality and precision, they offer end-to-end solutions tailored to a variety of industries.

In addition to offering 3D laser scanning services in Pune, RA Global Tech also supports innovation through 3D-printed prototype services in Mumbai. Whether you are a product designer or an engineer, their prototyping solutions can help bring concepts to life with fast, high-quality prints.

If you are located near Malad and searching for "3D scanners near me," RA Global Tech also caters to clients in this region, providing local access to global-grade scanning technology. Their expertise ensures that your scanning needs, be it for reverse engineering or detailed modeling, are met with professionalism and precision.

3D laser scanning is revolutionizing how businesses design, build, and innovate. From accurate site mapping to high-quality product design, this technology offers a versatile and reliable solution for today’s precision-driven industries. As demand continues to grow, 3D laser scanning service Pune stands out as an essential tool for anyone involved in architecture, engineering, manufacturing, and more.

For businesses in Pune and surrounding areas, RA Global Tech provides top-tier scanning services backed by experience, technology, and a commitment to excellence. Whether you are planning a complex construction project, preserving historical landmarks, or developing the next big product, RA Global Tech’s 3D scanning solutions offer the accuracy and efficiency you need to succeed.

In today’s world, climate change is an alarming issue that requires immediate attention. Our planet faces numerous environmental threats, many of which are exacerbated by human activity. The most viable solution to counter these challenges is to adopt sustainable practices at both individual and corporate levels. While individuals can make small yet meaningful changes, companies must take a proactive role in implementing sustainability from the ground up.

Sustainability focuses on meeting the needs of the present without compromising the ability of future generations to meet their own needs (Grant, 2020). This principle applies across industries, influencing how Manufacturing Services are designed, executed, utilized, and ultimately optimized for minimal environmental impact.

With increasing awareness, customers are demanding more sustainable products. However, rather than fully embracing sustainability, some companies resort to greenwashing—marketing their products as environmentally friendly without making significant changes. This deceptive practice must be replaced with genuine sustainability efforts that prioritize long-term environmental and social benefits.

The most effective way for companies to embrace sustainability is to embed it within their Product Design And Development Services. The decisions made at these stages determine a product’s environmental footprint, making it crucial to consider sustainability from inception.

Sustainable Manufacturing and Transportation: Companies should assess each phase of production with sustainability in mind. Reducing energy consumption, minimizing water waste, and opting for renewable resources in manufacturing can significantly lower environmental impact. Additionally, making products and packaging smaller and lighter enhances transportation efficiency, reducing fuel consumption and emissions.

Eco-Friendly Packaging: Packaging plays a crucial role in sustainability. Companies must move away from excessive and non-biodegradable materials, such as single-use plastics, in favor of greener alternatives. While sustainable packaging may not always be visually appealing or flashy, it has a far greater positive impact on the environment.

Fostering a Green Company Culture: Sustainable transformation starts from within. Companies need to cultivate a culture where sustainability is embedded in their values and operations. Employees should be encouraged to develop and implement eco-friendly solutions, reducing the overall environmental impact of products and business practices.

End-of-Life Considerations: Designing products with their end-of-life in mind is essential for sustainability. Companies can develop items that are recyclable, upcyclable, or biodegradable. A circular economy approach, where used products are repurposed or their components extracted for reuse, ensures minimal waste. For example, products can be designed so that companies can retrieve materials and repurpose them for future manufacturing.

Many businesses hesitate to adopt sustainable practices due to perceived high costs. However, sustainability is not just an ethical choice—it is a financially sound decision. Companies that implement green solutions often experience long-term profitability through cost savings, improved brand reputation, and customer loyalty. Sustainability benefits people, the planet, and profit, proving that environmentally conscious choices are a win-win for businesses and society.

Companies can no longer afford to take a backseat when it comes to sustainability. They must actively integrate eco-friendly practices into every stage of their operations. By doing so, they will not only reduce their environmental impact but also align with the growing demand for responsible business practices. The time to act is now—sustainability is no longer an option but a necessity for a thriving future.

The Hyperloop is a revolutionary transportation concept first introduced by Elon Musk in a 57-page white paper in 2013. This futuristic system envisions high-speed travel through a low-pressure tube, where passenger pods are suspended in air to eliminate friction and minimize air resistance. The result is an ultra-fast and efficient mode of transport that could surpass the speed of airplanes and high-speed rail networks.

By creating a near-vacuum environment within the tube, the Hyperloop drastically reduces drag, allowing the pods to travel at incredible speeds with minimal energy consumption. The propulsion system would use either magnetic levitation or air bearings to elevate the pods, ensuring a smooth and frictionless ride. Additionally, the hyperloop could be constructed both above ground and underground, offering flexibility in implementation based on geographic and infrastructural considerations.

The Hyperloop promises several advantages over traditional transportation systems, making it an exciting innovation for the future.

Speed and cost efficiency: One of the most significant advantages of the Hyperloop is its unprecedented speed. The system is expected to be at least twice as fast as commercial airplanes and significantly faster than high-speed trains. This means that long-distance travel times could be dramatically reduced, making cities and countries more interconnected than ever before. For example, a journey that currently takes hours by plane or train could be completed in minutes using the Hyperloop. This advancement in product design would revolutionize the way people commute and conduct business, leading to increased economic productivity. Additionally, while the initial costs of developing a Hyperloop network may be substantial, the long-term operational expenses are expected to be relatively low. Compared to high-speed rail construction, the Hyperloop would require less land and infrastructure, leading to lower maintenance costs. The energy-efficient design also means that running costs would be minimal, potentially making travel more affordable for passengers.

Environmental sustainability: The transportation industry is one of the largest contributors to global carbon emissions, and the Hyperloop presents a promising solution to reduce this impact. According to Musk’s white paper, the Hyperloop could be powered entirely by renewable energy sources, such as solar power. This would result in a system with a zero-carbon footprint, significantly reducing greenhouse gas emissions. By offering a cleaner alternative to air travel and road transport, the Hyperloop could play a crucial role in combating climate change and promoting sustainable mobility. With the world increasingly prioritizing eco-friendly transportation solutions, the Hyperloop represents a forward-thinking step towards a greener future.

Versatile applications: Beyond passenger travel, the Hyperloop has the potential to revolutionize cargo transportation. The ability to move goods at high speeds could enhance global supply chains, reduce reliance on trucks and airplanes, and lower overall transportation costs for businesses. Additionally, airports could integrate Hyperloop systems to improve passenger mobility between terminals, enhancing efficiency and convenience. Shipping docks could also benefit from the technology, using Hyperloop tubes instead of trucks to transport goods over short and long distances.

While the hyperloop presents a promising vision for the future, several challenges must be addressed before it can become a viable transportation option.

Land acquisition and infrastructure constraints: One of the biggest obstacles to implementing the hyperloop is securing the necessary land for construction. The system requires a straight path between destinations, as its high speeds make sharp turns unfeasible. Acquiring this land may be difficult, especially if the route crosses UNESCO heritage sites, residential areas, or protected landscapes. Governments and developers will need to navigate complex legal and regulatory issues to obtain permission for land use. Additionally, some communities may resist Hyperloop projects due to concerns about property displacement, environmental impact, and aesthetic disruptions.

Safety and disaster resilience: Passenger safety is a crucial consideration for any transportation system, and the Hyperloop is no exception. Since the concept is still in its experimental stage, there are concerns about how the system would handle emergencies such as earthquakes, mechanical failures, or power outages. Unlike traditional trains or planes, where passengers can evacuate in the event of an emergency, the enclosed nature of the Hyperloop poses unique challenges. Developers must establish comprehensive safety protocols, including fail-safe mechanisms, emergency exits, and rapid-response solutions to ensure passenger well-being in case of accidents or natural disasters.

Passenger comfort and health concerns: The Hyperloop’s ultra-high speeds could present challenges related to passenger comfort. The conceptual design suggests that the pods will have limited space, restricting movement and possibly causing discomfort during long journeys. Moreover, the rapid acceleration and deceleration could lead to motion sickness or dizziness for some passengers. Addressing these issues will require innovative solutions, such as advanced stabilization systems, comfortable seating arrangements, and onboard medical support for emergencies.

Despite these challenges, progress is being made towards bringing the Hyperloop concept to life. Several companies, including Virgin Hyperloop and Hyperloop Transportation Technologies, have been actively prototyping and refining the technology. Governments and private investors are also showing increasing interest in funding research and infrastructure projects related to the Hyperloop.

Countries such as the United States, India, and the United Arab Emirates have proposed potential routes for Hyperloop implementation, with feasibility studies already underway. If successful, the Hyperloop could revolutionize global travel, reducing congestion on roads and in the skies while offering a fast, sustainable, and cost-effective alternative.

As engineering and science continue to refine the technology, addressing safety concerns and improving passenger experience will be critical to making the Hyperloop a mainstream transportation mode. If these hurdles are overcome, we may soon witness a new era of travel that reshapes how we connect with the world.

The Hyperloop represents a groundbreaking leap forward in transportation technology, with the potential to redefine the way people and goods move across vast distances. Its speed, efficiency, and environmental benefits make it an attractive alternative to traditional transport methods. However, significant challenges remain, including land acquisition, safety concerns, and passenger comfort.

With continued innovation, investment, and regulatory support, the Hyperloop could become a reality within the next few decades, bringing with it a new age of high-speed, sustainable, and interconnected travel. The journey towards realizing this ambitious vision is just beginning, but its impact on the future of transportation could be profound.

Back in the day pigeons were used to relay messages between individuals, as the sky was the fastest and safest passage at the time. It seems like the sky is going to be the future of transportation of packages and people as well. With the constantly increasing population, there is an urgent need to find solutions for the traffic and the hours individuals waste stuck in it. With constantly advancing technology, there is hope for a more systematic and efficient system to come into place.

There are several reasons why the world is looking to the skies for solutions. With individuals migrating to cities constantly, the population and the number of vehicles on the roads are also increasing. Reconstructing roads to be broader in these densely populated cities is impossible, making flying cars crucial. Furthermore, reaching remote places is often a challenge for individuals, comprising long travel hours on poorly constructed roads with no medical assistance available if necessary in case of accidents. Having a flying car would make it much easier to access these locations and even deliver packages. Similarly, in the case of natural catastrophes, flying cars and drones could be used to drop off care packages and medicines and even be used to rescue individuals.

The e-commerce and automotive industries are two industries that are researching and developing this technology. The automotive industry is working on vertical take-off and landing technology that is more suitable for urban settings, eliminating the need for runways for take-off. Making flying cars energy-efficient and silent is another requirement that must be fulfilled. There is a need to make all drones and cars autonomous as well as create technology through which all of them can communicate and work independently.

While the flying car dream seems near, many individuals are skeptical about its success. Several hurdles will have to be crossed, the first being that governments and countries will have to lay down specific air traffic rules and regulations and invest in infrastructure for building parking and charging stations. The second hurdle will essentially be regarding safety issues and weather, as extensive testing by manufacturers will be required for passengers to trust these autonomous vehicles. Several emergencies will have to be thought through to ensure complete safety and fewer fatalities, and the drones and cars will have to be able to work under any circumstances. The third hurdle would be that there might come a point where traffic will shift to the air, and authorities will have to look for ways to mitigate that.

This technology, if implemented, has the opportunity to solve several problems of the urban world. While this may not be possible for the next few years, it is the future, and individuals must capitalize on the chance to invest in it today.

With rising concerns over global warming, individuals and governments all around the world are becoming conscious of their carbon footprints. Internal Combustion vehicles are one of the biggest contributors to pollution, and according to the Environmental Protection Agency, a car emits about 4.6 metric tons of carbon dioxide per year. The need for an alternative to the traditional fossil fuel car has never been more fundamental to the progress of our planet. One such promising alternative that is being heavily spoken about is the electric vehicle. It has the potential to result in a green transportation system, as electric vehicles require just electricity to run.

From the point of view of sustainability, an electric car has no tailpipe emission of Chlorofluorocarbons (CFCs), safeguarding us from air pollution that may cause respiratory diseases along with global warming. Using electricity is a much more sustainable method, as the requirement of fossil fuel for a really large sector gets eliminated. Additionally, as electric vehicles lack several regular car parts, when disposed of, electric vehicles cause relatively less pollution, and oil leak contamination is eliminated. With the presence of green transportation, other industries too will be motivated to take sustainable steps, as using renewable energies for daily activities will not seem so unattainable anymore.

Electric vehicles have several other benefits. The most obvious of which is that fuel costs surpass the costs of electricity by a huge margin, resulting in long-term savings. Structurally, the vehicle lacks a combustion engine, as it does not run on fuel and hence, makes no noise, assisting in the reduction of noise pollution and providing a better driving experience. They are also deemed safer due to the lack of flammable material present, which will result in fewer fire-related accidents. Furthermore, some electric vehicles may also have a low center of gravity, depending on where the batteries are placed and the size of the engine, making them less likely to flip over. Due to the lack of integral moving car parts, electric vehicles are also relatively low maintenance, as no oil changes or new fuel filters are required.

A common issue for the sustainability of electric vehicles is that the point source—the electric grid—may use coal to generate the energy, hence, still releasing emissions into the atmosphere. To eliminate this issue, charging stations must be installed with solar panels instead of being connected to an electric grid to provide cleaner energy. Batteries are another highlighted issue, as lithium mining causes land degradation and severe water pollution, harming ecosystems. With the increase in electric cars, the demand for lithium will rise, causing a negative impact on the environment. To reduce the impact of this, lithium mining could be heavily regulated, and environmental regulation could be put in place. Batteries used in these vehicles could also be recycled constantly.

While several challenges persist in the future success of electric vehicles, in order to increase the popularity and convenience of this technology, governments must undertake certain steps. Building infrastructure is key to the success of electric vehicles. Charging stations must be available at convenient locations all over cities and highways. Governments must also invest in clean energy sources and build clean grids to ensure low emissions. Incentives such as discounted taxes upon purchase of electric vehicles could be used to motivate citizens to buy these vehicles.

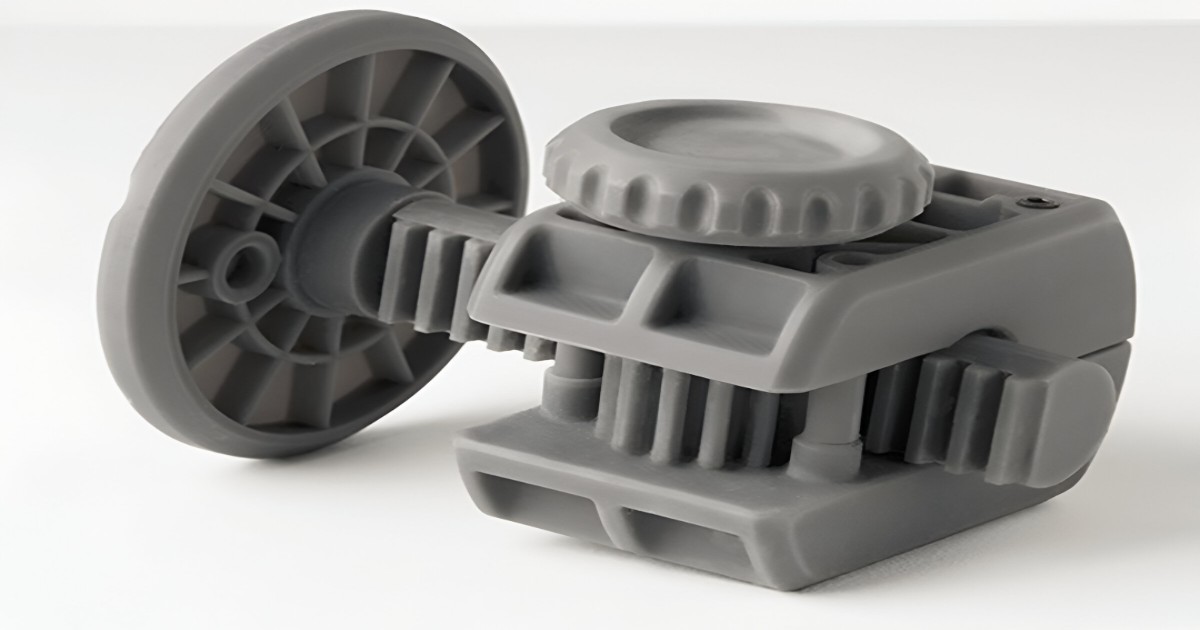

Additive manufacturing (AM) was invented in the mid-1980s in Japan, after which it soon became well-known for rapid prototyping all over the world. Additive manufacturing, also known as 3D printing, is a technology that builds objects by adding material layer by layer. Materials used in this method can range from plastics, metals, ceramics, and cement, amongst many others. Today, it is being utilized in several industries: aerospace, healthcare, automotive, construction, and manufacturing to produce final product parts. This method has become more tangible in recent years and is the future for engineers and the manufacturing industry.

Bringing additive manufacturing into mainstream bulk manufacturing will shockingly reduce production costs while simultaneously improving the quality of the product. Unlike traditional methods of manufacturing, additive manufacturing does not require the building of molds or any special machinery; a single Computer-Aided Design software file is the only pre-production element necessary.

A single additive manufacturing machine is capable of working with different materials to produce a vast array of products, hence reducing investment costs greatly. Labor costs are relatively low, as there is no requirement for assembling, as the product is made as a single part. The quality of the product is much superior, as materials such as carbon fibers and titanium can be integrated easily into the product. The entire process of making a finished product has no human interference, hence eliminating the possibility of any human error that may occur during a traditional manufacturing process and also increasing the rate of production by several folds.

Traditionally, a manufacturer's production ability would decide the structural design of the product. But with the introduction of 3D printing services, the power is in the hands of engineers, and they have total liberty to design as they envision the product. Customization of products based on the customers' needs at lower costs is a much more plausible concept with 3D printing. Professionals in the healthcare industry are looking to create replacement parts and bones specific to their patients' needs for a higher success rate and reduced infections. This technology is also proving to be a game-changer for the aerospace industry, as lighter but more durable parts can be made. In space astronauts and engineers use 3D printing to print crucial parts in case of emergencies. Another impeccable feature of additive manufacturing technology is that modifications and adjustments to the product design can be made at any moment without increasing costs or slowing down the production process.

The environment also benefits greatly from this process. Due to the lack of raw materials needed to mold or color the product, there is a significant drop in the waste generated. Often machines also release toxic waste while producing products, which is then released into freshwater bodies and oceans, causing water pollution. Some products made by traditional machines also require burring and heating, which release toxins into the air. With the use of 3D printing, no materials are wasted and no form of pollution is caused.

There are several challenges to the scaling of 3D printing to become the new ordinary form of production. There needs to be more research and development done in this area to improve upon materials and efficiency and reduce initial setup costs. Engineers need to be more open to experimenting and educating themselves about additive manufacturing, and countries need to improve their digital framework to ensure the success of this promising method. Several hurdles stand in the way of the success of this manufacturing method, but it is capable of being the next industrial revolution that will benefit consumers, business owners, and the environment alike.

© 2026 RA Global Tech Solutions

Site design and developed by Rajkar Global