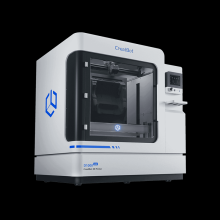

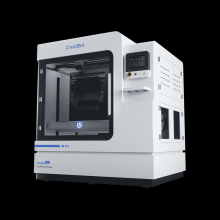

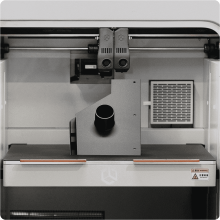

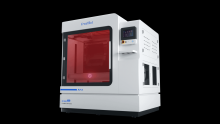

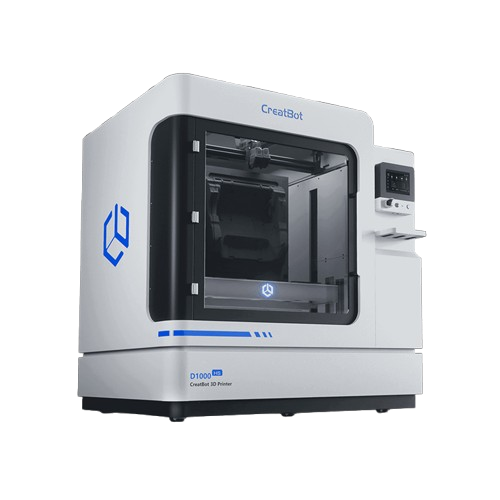

Creatbot D1000 HS 3D Printer

One Cubic Meter Industrial Grade Large 3D Printer

The D1000 HS is upgraded from the model D1000; it is a new high-speed printing version based on the in-depth development of Klipper. It adopts a new hotend with a flow rate of up to a record-breaking 90 mm³/s. The stable printing speed can reach 300 mm/s, which is 5 times the speed of the D1000 model.