Rapid Prototyping

What is product engineering?

Product engineering involves the application of engineering principles and techniques to design, develop, and test a product. The comprehensive process of bringing a product from concept to market, encompassing design, development, testing, and manufacturing. By leveraging engineering expertise and innovative techniques, product engineering creates products that are functional, reliable, and tailored to customer needs and market demands.

What is rapid prototyping?

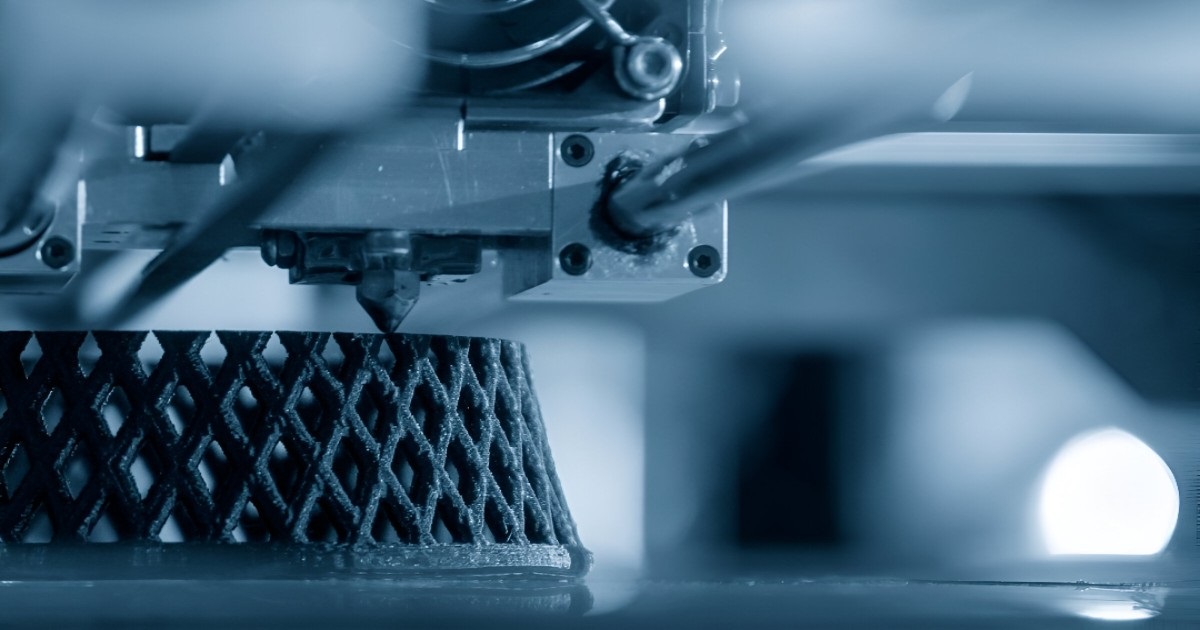

Rapid prototyping is a methodology used to quickly create a functional prototype of a product or system. A fast and efficient approach to creating physical models or prototypes from digital designs. By leveraging cutting edge technologies like 3D printing and CNC machining, rapid prototyping enables the swift transformation of ideas into tangible, testable products. This approach enables businesses to:

- Validate Product Ideas: Test product assumptions and gather feedback.

- Refine Product Design: Iterate on the design based on feedback and testing results.

- Reduce Development Time: Accelerate the development process by identifying and addressing potential issues early on.

Key Aspects of product engineering and rapid prototyping:

- Conceptualization and Design Development: The process begins with ideation and concept design, where engineers translate ideas into initial sketches, 2D drawings, or digital models. This stage focuses on functionality, usability, and feasibility, ensuring that the product concept aligns with customer requirements and market needs.

- CAD Modeling and Simulation: Using Computer-Aided Design (CAD) software, detailed 3D models are created. These models allow for virtual testing and simulation, including stress analysis, thermal performance, and motion studies. Simulation helps identify design flaws early, reducing development time and cost.

- Material Selection: Choosing the right materials is a critical aspect of product engineering. Engineers evaluate mechanical properties, durability, flexibility, and cost effectiveness to select materials that meet performance requirements for the prototype and final product.

Why product engineering and rapid prototyping is important?

Product engineering and rapid prototyping are crucial steps in modern manufacturing and product development, enabling businesses to efficiently transform ideas into functional, market-ready products. These processes accelerate the time-to-market by allowing designers and engineers to quickly create physical models, test them, and implement improvements, ensuring faster product launches and responsiveness to market demands. By identifying design flaws, material issues, or functional problems early in development, rapid prototyping reduces costly errors during mass production, saving both time and resources.

Prototypes provide hands-on evaluation of form, fit, and function, enabling engineers to perform functional tests, usability assessments, and performance evaluations to ensure products meet all requirements and comply with safety and quality standards. Additionally, rapid prototyping fosters innovation by allowing experimentation with different designs, materials, and configurations without committing to full-scale production, resulting in more creative and optimized products. Iterative development also improves product quality, enhancing reliability, durability, and manufacturability while reducing defects.

What are the common challenges in product engineering and rapid prototyping?

Product engineering and rapid prototyping come with several challenges, including managing complex designs and ensuring manufacturability, selecting suitable materials, and balancing development time and costs while maintaining quality. Effective collaboration and communication among cross-functional teams are also crucial. Additionally, achieving accurate prototypes, designing for scalability, ensuring regulatory compliance, managing suppliers, and thorough testing and validation are key hurdles. By understanding these challenges, product engineers and development teams can proactively address them and ensure successful product development.

The Process

- Concept Development: The process begins with ideation and requirement analysis, where engineers and designers understand the product vision, functionality, and market needs. Initial sketches, concept drawings, and functional specifications are created to define the project scope.

- CAD Modeling and Simulation: Concepts are converted into 3D CAD models, allowing for virtual testing and simulations. This includes stress analysis, thermal performance, motion studies, and tolerance checks. Simulation identifies potential design flaws early, saving time and reducing material waste.

- Material Selection: Selecting the appropriate material is critical for both prototypes and final products. Factors such as mechanical strength, flexibility, durability, cost, and compatibility with manufacturing processes are considered to ensure optimal performance.

- Prototype Fabrication: Using rapid prototyping techniques like 3D printing, CNC machining, or additive manufacturing, physical prototypes are created quickly. These prototypes allow for hands-on evaluation, functional testing, and design validation, providing a tangible representation of the concept.

- Testing and Validation: Prototypes undergo functional, structural, and usability testing to validate their performance. Any issues identified during testing are addressed through iterative design improvements, ensuring the product meets all specifications and requirements.

- Design Iteration and Optimization: Based on testing feedback, engineers refine the design, optimizing geometry, material use, and structural features. This iterative process continues until the prototype achieves the desired functionality, quality, and manufacturability.

- Manufacturing Readiness: Once the prototype is validated, the design is prepared for mass production. This includes tooling design, process planning, and manufacturability analysis to ensure smooth and cost-effective transition from prototype to production.

- Quality Assurance and Final Validation: Final prototypes and production-ready designs undergo quality checks, dimensional verification, and compliance assessments to guarantee reliability, performance, and adherence to industry standards.

What are the applications of product engineering and rapid prototyping across various industries?

- Automotive Industry: In the automotive sector, rapid prototyping and product engineering are used to develop engine components, chassis parts, interior fittings, and custom assemblies. Prototypes allow for functional testing, design validation, and ergonomic evaluation, ensuring high performance, safety, and reliability before mass production.

- Aerospace Industry: Aerospace components require high precision, lightweight structures, and exceptional durability. Product engineering and rapid prototyping help create turbine blades, airframe components, and cockpit assemblies, allowing engineers to test aerodynamics, structural integrity, and compliance with strict aerospace standards.

- Medical and Healthcare Industry: Prototyping is critical for surgical instruments, implants, prosthetics, and medical devices, where precision and regulatory compliance are essential. Engineers can validate functionality, test materials, and ensure safety before moving to production, reducing risks for end users

- Consumer Electronics: For electronics, rapid prototyping enables the development of housings, connectors, and circuit assemblies, helping designers evaluate fit, functionality, and aesthetic appeal. It allows quick iterations to improve product ergonomics, usability, and performance.

- Industrial Machinery and Equipment: In heavy machinery and industrial equipment, prototypes are used to test components like gears, valves, pumps, and structural assemblies. Product engineering ensures that parts are durable, reliable, and optimized for manufacturability, reducing downtime and enhancing operational efficiency.

- Oil and Gas Industry: Prototyping and product engineering support valves, fittings, seals, and high-pressure components, ensuring they can withstand extreme conditions, temperature variations, and mechanical stress. Testing prototypes helps prevent failures and ensures safety in critical applications.

- Rubber, Plastic, and Molded Components: Rapid prototyping is used to develop gaskets, O-rings, seals, and custom molded parts, allowing for fit verification, functional testing, and iterative design improvements before full scale production.

Why choose RA Global?

We combine cutting-edge technology, skilled expertise, and a client-centric approach to deliver high quality, market ready solutions that meet diverse industry needs.

- Expertise and Experience: We have skilled team with industry knowledge.

- Advanced Technology: State-of-the-art tools and equipment.

- End-to-End Solutions: Comprehensive services for seamless product development.

- Quality Assurance: Rigorous testing and compliance protocols.

- Innovation: Custom solutions and creative approach.

- Customer Focus: Collaborative and client-centric approach.

Frequently Asked Questions

What is rapid prototyping?

It’s the fast creation of physical models from digital designs, helping evaluate form, fit, and function before full-scale production begins.

Why choose RA Global for prototyping?

We offer advanced 3D printing, CNC machining, and expert design support to quickly deliver accurate, high‑quality prototypes tailored to your needs.

Which industries use rapid prototyping?

The Automotive, Consumer Products, Medical Devices, Industrial Equipment, and Electronics Industries use it for testing, design validation, and product development.

What materials do you use for prototypes?

Plastics, metals, and composites are selected to match your product’s Functional, Aesthetic, and Mechanical requirements during testing and evaluation.

Can you help refine product designs?

Yes! We review and optimize designs to improve manufacturability, performance, and appearance, helping speed up the path to final production.