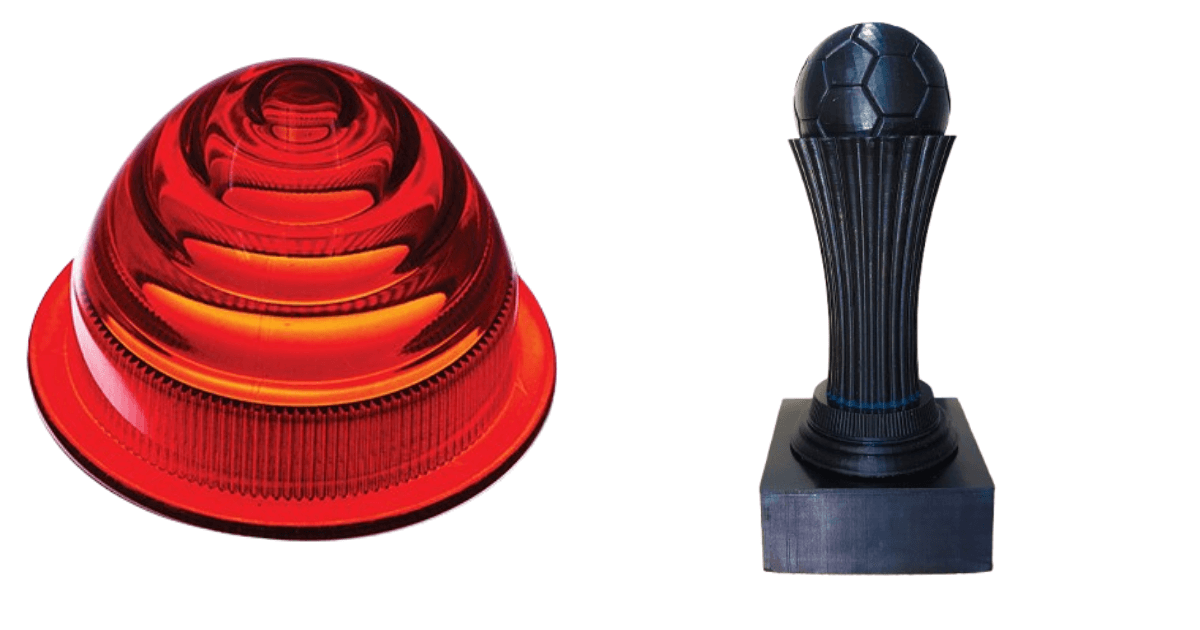

SLA (Stereolithography) is a high-precision 3D printing technology that uses a UV laser or light projector to cure liquid photopolymer resin layer by layer, resulting in parts with exceptional detail and accuracy. As one of the earliest forms of additive manufacturing, SLA is renowned for its ability to produce smooth surface finishes, fine features, and tight tolerances that other technologies struggle to achieve. The precision of SLA makes it ideal for intricate designs, complex geometries, and components requiring high dimensional accuracy.

Because of its reliability and superior surface quality, SLA is widely used across industries such as healthcare, aerospace, automotive, consumer products, and engineering. Whether for functional prototypes, aesthetic models, or production-grade components, SLA delivers outstanding resolution and consistent part quality. Its ability to reproduce micro-details, thin walls, and highly accurate fits makes SLA one of the most versatile and powerful additive manufacturing technologies available today.

Stereolithography (SLA) 3D printing builds parts by curing liquid photopolymer resin layer by layer with a high-precision light source. The process begins with a 3D CAD model, which is sliced into extremely thin horizontal layers. These slices guide the printer on where to solidify the resin to form each successive layer of the part.

The build platform is then lowered into a vat filled with liquid photopolymer resin. A UV laser or digital light projector selectively illuminates the resin according to the current slice of the model. The exposed regions undergo photopolymerization, a chemical reaction that hardens the liquid resin into a solid. Areas not exposed to light remain liquid, ensuring that only the desired geometry is created.

After a layer is cured, the build platform raises slightly, allowing a fresh layer of resin to flow over the previous layer. This ensures uniform coverage and consistent layer thickness. The process repeats layer by layer, gradually building the part from the bottom up with high precision and fine feature detail.

Once printing is complete, the part is carefully removed from the vat and washed to remove any uncured resin, typically using isopropyl alcohol. Finally, the part undergoes post-curing under UV light, which fully solidifies the polymer and enhances its mechanical strength, stability, and chemical resistance, resulting in a finished component ready for functional use or further post-processing.

At RA Global Tech Solutions, we have the expertise and experience to leverage SLA 3D printing for your business needs. Our team will work closely with you to:

SLA 3D printing offers a range of benefits, from high resolution to complex geometries. At RA Global Tech Solutions, we're committed to harnessing the power of SLA 3D printing to drive innovation and growth. Contact us today to learn more about how SLA 3D printing can benefit your business.

We manufacture your parts according to strict manufacturing standards. Verification of these requirements is included in our inspection report that is shipped with every order.

UPLOAD your design for an Instant Quote (acceptable file types are .stl, .step, and .x_T).

SLA is a resin-based additive process that uses a laser to selectively cure (harden) liquid photopolymer resin in a vat, building the part layer by layer.

SLA provides the highest resolution and surface smoothness of any plastic 3D printing technology. It is ideal for highly detailed parts with intricate features and tight tolerances.

SLA uses thermoset liquid photopolymer resins, which come in various formulations (e.g., tough, flexible, clear, dental, or high-temperature). These parts often require UV light post-curing for final properties.

SLA offers excellent dimensional accuracy, typically within a tolerance of $\pm0.05$ to $\pm0.15$ mm. Its precision makes it popular for fit-and-finish prototypes and small, complex functional parts.

SLA is widely used for master patterns for casting, highly detailed prototypes, custom ear molds, and detailed dental models due to its superior surface quality and accuracy.

© 2026 RA Global Tech Solutions

Site design and developed by Rajkar Global