Ever wonder how a simple idea turns into something people actually use? Behind every successful product lies a structured journey called the Product Life Cycle. At RA Global, a leading mechanical engineering company in Mumbai, we understand the importance of each stage in this journey and provide advanced Computer-Aided Engineering (CAE) services to ensure every product is reliable, durable, and high-performing.

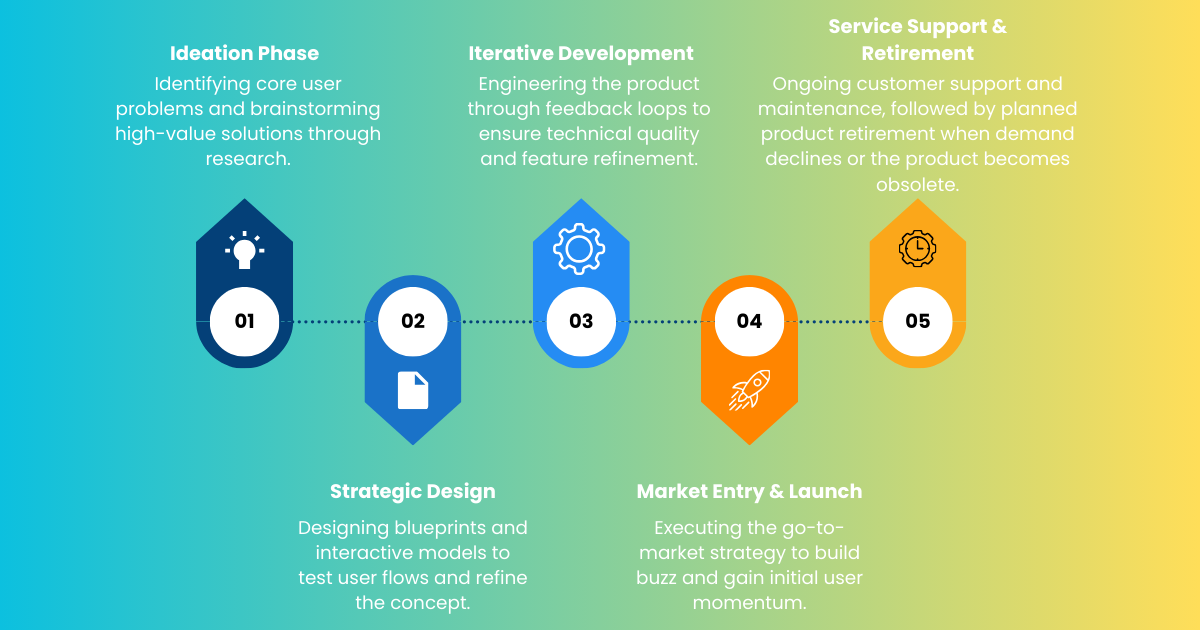

Every great product begins with asking the right questions rather than assuming the answers. In this stage, industries focus on understanding the market, identifying customer pain points, and analyzing consumer requirements to uncover opportunities for innovation. This involves extensive market research, competitor analysis, trend observation, and feedback collection to ensure the idea addresses real-world needs. Once potential solutions are identified, teams engage in brainstorming and conceptual design, translating insights into feasible product concepts. This is followed by engineering efforts for both hardware and software, creating initial prototypes or models to validate technical feasibility. Finally, testing concepts and integrating suppliers ensures the product is practical, manufacturable, and aligned with production capabilities. At RA Global, our engineers leverage industry expertise and advanced CAE tools to provide actionable insights that guide innovative and sustainable product designs.

Before committing significant resources to production, it is critical to validate the concept. Strategic prototyping enables companies to reduce risk and cost, gather real feedback, and streamline development. This phase often includes developing interactive models, user flows, and proof-of-concept prototypes to test usability and functionality. RA Global supports clients by simulating real-world conditions through advanced FEA services, helping teams identify potential design weaknesses early and ensuring that only robust and validated concepts move forward. Effective prototyping not only validates ideas but also attracts investment and guides decision-making, creating a blueprint for successful product development.

Engineering is an iterative conversation, not a one-way process. During iterative development, products are built in cycles, releasing features, gathering user feedback, and refining the design to enhance quality and performance. This approach ensures the final product is polished and truly market-ready. Key steps include planning and research, designing and prototyping, implementing and testing, evaluating feedback, and refining the solution. RA Global’s advanced CAE and FEA tools allow teams to simulate stresses, optimize performance, and verify product reliability, helping engineers make informed design improvements throughout development.

A product can only succeed if the right audience knows about it. The market entry and launch phase involves executing a go-to-market strategy, including planned distribution, targeted marketing campaigns, and brand-building activities to generate anticipation and attract early users. RA Global ensures that products are technically robust and performance-ready at launch, giving companies confidence that their designs will function flawlessly in real-world conditions. By combining engineering precision with strategic launch planning, businesses can capture initial interest and convert it into lasting market momentum.

After launch, maintaining product value and customer satisfaction is crucial. This phase includes post-installation support, routine maintenance, and proactive engagement with customers to ensure long-term usability. Managing obsolescence and guiding users toward updated solutions or new product versions is equally important. RA Global assists clients in extending product life cycles and ensuring reliability, providing ongoing engineering insights and CAE support to maximize performance, safety, and customer satisfaction.

An engineering team at an automotive supplier identifies that existing brake calipers are too heavy and inefficient for the rapidly growing EV market, reducing range and requiring more frequent pad changes due to the regenerative braking systems in EVs. Activities include conducting market research on EV trends, current brake system limitations, and potential customer pain points such as weight and heat dissipation; brainstorming potential solutions like lightweight alloys, innovative cooling mechanisms, or new actuator designs; and concept testing with potential automotive manufacturers to gauge interest and validate the idea.

The team decides on a design featuring a single-piston, aluminum-lithium alloy caliper with integrated fluid channels for enhanced cooling.

Key activities include detailed engineering design using Computer-Aided Design (CAD) software, material selection and analysis to meet strength and weight requirements, simulation and analysis via Finite Element Analysis (FEA) to predict performance, creating a product roadmap with development goals, timelines, and metrics, and prototyping initial physical models for testing.

The engineering team develops several prototypes of the new caliper. These are subjected to lab and track testing. Activities include building a minimum viable product (MVP) for initial testing, rigorous testing for durability, heat management, and braking performance, gathering feedback from test drivers and engineers, and refining the design based on performance data, such as adjusting the alloy composition or fluid channel dimensions, and repeating this process until the product meets all requirements.

The new EV brake caliper is ready for commercialization. The supplier signs a contract to provide the calipers to a major EV manufacturer. Activities include planning the go-to-market strategy and setting up supply chains, marketing and promoting the product to other potential customers, initial release to a specific market segment to gauge adoption and performance, and ramping up production to meet growing demand as sales increase.

The brake calipers are in use across several EV models. Activities focused on service and support, including providing maintenance manuals and spare parts, monitoring product performance, and releasing updated versions or new product lines based on feedback and technological advancements. As the product nears retirement, plans are made for phasing out production, responsible recycling of aluminum-lithium components, and transitioning to newer, superior versions, such as a fully electric braking system, as industry standards evolve and sales decline.

RA Global is a leading mechanical engineering company based in Mumbai, providing advanced Computer-Aided Engineering (CAE) and Finite Element Analysis (FEA) services in India and globally for over two decades. Our team of highly skilled engineers possesses extensive expertise across diverse industries, including automotive, aeronautical, and heavy-structure sectors, delivering precise, innovative, and sustainable solutions. At RA Global, we focus on quality by understanding how components behave under various loading conditions, ensuring that every product we analyze or design achieves maximum reliability, durability, performance, and stability. Leveraging cutting-edge FEA software and advanced CAE techniques, we support our clients throughout the entire product journey from ideation to market launch and beyond. Our pan-India reach ensures smooth, timely, and consistent project execution across multiple cities, providing top-tier engineering services that exceed expectations and offer an unparalleled client experience.

RA Global supports clients across critical stages of the Product Life Cycle, particularly during the design validation and pre-production phases, by enabling early verification of design intent for customers in Muscat, the United Kingdom, and the UAE.

© 2026 RA Global Tech Solutions

Site design and developed by Rajkar Global