MJF 3D Printing: Multi Jet Fusion

What is MJF 3D printing?

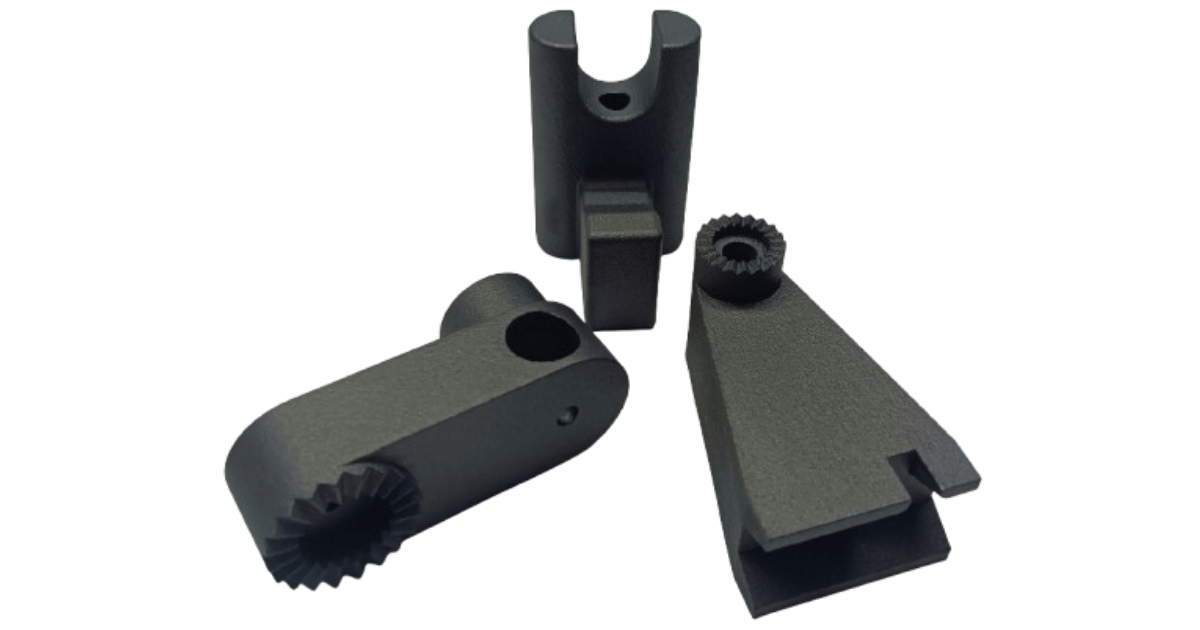

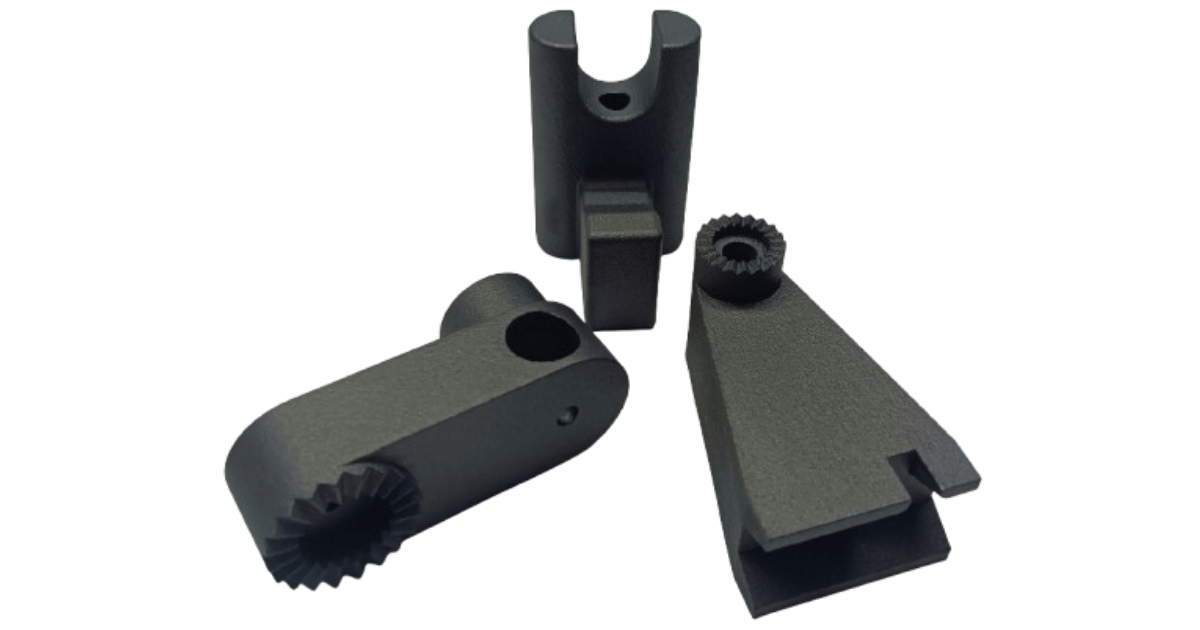

Multi Jet Fusion (MJF) is an industrial-grade polymer additive manufacturing process developed by HP, engineered to produce high-strength, dimensionally accurate, and geometrically complex parts. Unlike conventional 3D printing methods, MJF uses a thermal inkjet fusion mechanism where fusing and detailing agents are precisely jetted onto a powder bed and then solidified using infrared energy. This process enables exceptional mechanical consistency, fine feature resolution, smooth surface quality, and near-isotropic material properties, making MJF suitable for both functional prototypes and end-use production components. Its ability to deliver consistent results, fast production cycles, and cost-efficient manufacturing makes MJF a preferred technology across a wide range of industries.

At RA Global, we leverage the full potential of Multi Jet Fusion (MJF) to deliver high-precision polymer components tailored for demanding engineering applications. With state-of-the-art MJF systems and deep expertise in additive manufacturing, we provide parts that meet strict mechanical, dimensional, and performance requirements. Our focus on quality, reliability, and rapid production ensures that industries benefit from superior part accuracy, faster turnaround times, and scalable manufacturing solutions powered by modern MJF technology.

Key Aspects of MJF 3D Printing:

- Precision and Accuracy: MJF prints with extremely high dimensional accuracy (±0.2 mm or ±0.2%), enabling the creation of mechanically tight-fitting parts.

- Pixel-level Control: Each point in the part is represented as a voxel (3D pixel), allowing control of density, surface texture, mechanical strength, and color.

- Consistent Mechanical Properties: Unlike SLS and FDM, which suffer from anisotropy, MJF produces uniform strength throughout the part.

- No Support Structures: The powder bed naturally supports the part, reducing the need for support removal and enabling more complex geometries.

- High-speed Layering: Instead of scanning each region individually, MJF fuses an entire layer at once, making it significantly faster for batch production.

- Excellent Surface Quality: Surface roughness is lower compared to powder-bed fusion systems, minimizing post-processing.

How does MJF 3D printing work?

- CAD File Preparation: The 3D model is exported in STL or 3MF format and converted into fine voxel-based slices. The MJF software analyzes the design, determining heat distribution, agent placement, and scanning paths to ensure accurate layer fusion and dimensional stability.

- Powder Layering: A thin polymer powder layer (~80 microns) is spread across the build platform. A precision recoater ensures uniform thickness, directly affecting surface quality, accuracy, and part strength.

- Agent Jetting: High-precision printheads deposit fusing and detailing agents. The fusing agent solidifies intended areas, while the detailing agent sharpens edges and prevents excess melting, enabling high accuracy and consistent fusion.

- Infrared Fusion: A high-intensity IR lamp melts the powder in fusing-agent regions while preserving edges treated with the detailing agent, forming dense, mechanically strong, and dimensionally accurate layers.

- Layer-by-Layer Construction: The cycle of powder spreading, agent jetting, and IR fusion repeats for each layer, gradually building the part with full structural integrity and near-isotropic mechanical properties.

- Controlled Cooling: The build is slowly cooled in a dedicated station to prevent warping, internal stresses, and dimensional deformation, ensuring stable, accurate parts.

- Depowdering and Post-Processing: Residual powder is removed via air or bead blasting, followed by optional finishing such as dyeing, vapor smoothing, or CNC machining for precision features, resulting in fully functional, production-ready components.

Types of materials used in MJF 3D printing

- PA12 (Nylon 12): Offers high tensile strength, excellent dimensional stability, and good chemical and moisture resistance, making it ideal for robust mechanical parts. Applications: Housings, hinges, jigs, fixtures, and brackets.

- PA11 (Bio-based Nylon): Flexible and impact-resistant, with sustainable, eco-friendly properties. Perfect for lightweight or flexible components. Applications: Prosthetics, sports equipment, snap-fit features.

- PA12 Glass Bead (PA12 GB): Contains 40% glass beads for increased stiffness, heat resistance, and reduced creep over time. Applications: Automotive housings, structural brackets, tooling.

- TPU 88A / TPU 90A: Rubber-like elasticity with high abrasion resistance and excellent energy return. Applications: Seals, tubes, lattice structures, handles, cushions.

MJF 3D printing capabilities

- Large Build Volume: 500 mm x 500 mm x 500 mm

- Fast Turnaround Time: Reducing time-to-market for products

- High Dimensional Accuracy: ± 0.2% with a lower limit of ± 0.127 mm

- High-Resolution Printing: 50-100 μm

Design guidelines for MJF 3D printing

- Wall Thickness: Minimum wall thickness of 0.5-1 mm is recommended to ensure structural integrity

- Feature Size: Minimum feature size of 0.5-1 mm is recommended to ensure accuracy and detail

- Hole Size: Minimum hole size of 1-2 mm is recommended, depending on the application and required accuracy

- Radius and Fillets: Adding radii and fillets can improve part strength and reduce stress concentrations

- Draft Angle: A draft angle of 1-2° is recommended to facilitate part removal from the powder bed

Benefits of MJF 3D printing

- Speed: MJF 3D printing is significantly faster than other powder-based technologies, making it ideal for high-volume production.

- Accuracy: MJF parts exhibit high dimensional accuracy and surface finish, reducing post-processing requirements.

- Material Properties: MJF parts demonstrate excellent mechanical properties, including strength, durability, and thermal resistance.

- Complex Geometries: MJF enables the creation of intricate designs and complex geometries, allowing for innovative product development.

Applications of MJF 3D printing

- Industrial Parts: MJF is suitable for producing functional parts, such as gears, bearings, and other mechanical components.

- Product Prototyping: Rapid prototyping with MJF enables designers and engineers to test and iterate on product designs.

- Production Parts: MJF's high production speed and accuracy make it an attractive option for end-use parts.

RA Global stands out from the competition in a few key ways. Here are just a few reasons to choose us for your next MJF project:

- Save Time: Our MJF printers are incredibly fast, allowing us to create complex parts and products in a matter of hours rather than days or weeks. By utilizing this approach, you can speed up the process of bringing your products to the market, which will grant you an advantageous position within your industry.

- High-Performance Materials: Our MJF printing process employs premium materials to guarantee the durability, strength, and longevity of your parts and products. This ensures that your products will perform exceptionally even under the most extreme circumstances.

- Quality Assurance and No Limitation: At RA Global, we prioritize quality, thus implementing a meticulous quality assurance procedure to guarantee that all our components and goods satisfy our elevated criteria. Our MJF printers can create parts and products with incredible precision and detail, meaning there are no limitations to what we can create.

- Cost-Saving: Our MJF printing services are incredibly cost-effective, allowing you to create complex parts and products without breaking the bank. You can bring your products to the market quicker with our prompt turnaround times, resulting in long-term cost savings.

MJF 3D printing offers a range of benefits, from rapid production to complex geometries. At RA Global, we are committed to harnessing the power of MJF 3D printing to drive innovation and growth. Contact us today to learn more about how MJF 3D printing can benefit your business.

UPLOAD your design for an Instant Quote (Acceptable file types are .stl, .step, and .x_T.)

Frequently Asked Questions

What is MJF 3D Printing?

MJF is a powder bed fusion technology that uses an inkjet array to deposit fusing and detailing agents across a powder bed.

What are the primary materials used in MJF?

MJF primarily uses fine nylon powder (e.g., PA12, PA11) but can also process flexible materials like TPU and certain elastomers. These materials produce strong, lightweight, and durable parts.

What is unique about MJF's surface finish and quality?

MJF produces parts with a naturally fine and isotropic (uniform) surface finish right out of the printer. The parts boast excellent mechanical properties without needing extensive post-cure.

What are the key advantages of using MJF over other processes?

The main advantages are speed and cost-effectiveness for small- to medium-volume production runs. MJF also achieves exceptionally dense packing, which minimizes material waste and lowers part cost.

What is MJF commonly used for in industry?

MJF is widely used for functional prototyping and short-run manufacturing of end-use parts, including complex ducting, fixtures, housings, and custom components in the automotive and consumer goods sectors.