Injection Molding

What are injection molding services?

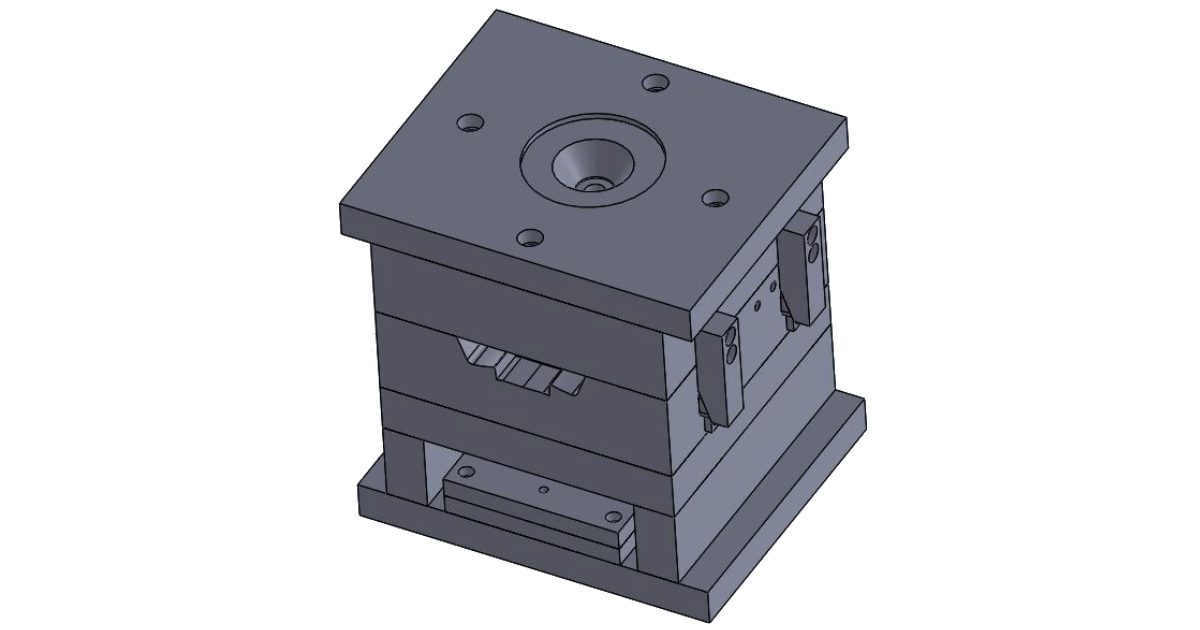

Injection molding is a manufacturing process in which molten material, typically plastic, is injected under high pressure into a precisely designed mold cavity. Once the material cools and solidifies, the mold opens to release a finished part with accurate dimensions and surface finish.

Injection molding services refer to the process of manufacturing parts by injecting molten material, typically plastic but sometimes metal or rubber, into a mold cavity, where it cools and solidifies into the desired shape. This method is one of the most widely used manufacturing techniques for producing high-volume, precise, and consistent parts.

Injection molding is ideal for creating complex geometries with tight tolerances and excellent surface finishes. The process involves several key stages, including mold design, material selection, injection, cooling, and ejection.

These services are used across various industries, such as automotive, medical, electronics, consumer goods, and packaging, providing efficient, cost-effective production for both prototypes and mass-produced components.

Injection Molding is a mold manufacturing procedure for making important parts with a specific shape and size. It is a versatile method that can be used to produce a wide variety of plastic parts, including toys, home appliances, automotive components, and industrial, scientific, and medical devices.

Key aspects of injection molding services:

- Mold Design: Creating precise molds to achieve desired part geometry and quality.

- Material Selection: Choosing suitable materials for the parts' application, durability, and aesthetic requirements.

- Injection Process: Controlling temperature, pressure, and flow rate to ensure part quality and consistency.

- Part Design Optimization: Designing parts for manufacturability, functionality, and cost-effectiveness.

- Quality Control: Implementing inspection and testing procedures to ensure part quality and reliability.

- Tooling and Maintenance: Maintaining and repairing molds to ensure optimal production efficiency.

Why are injection molding services important?

Injection molding services are important because they offer high-volume production, precision, and consistency in creating complex geometries with tight tolerances. This process is cost-effective, reducing labor costs and material waste, while also providing design flexibility and accommodating various materials. With fast production capabilities, injection molding is ideal for both prototypes and mass production, making it a crucial process for various industries that require high-quality parts and products.

What are the common challenges in injection molding services?

Injection molding services face several challenges that can impact efficiency, quality, and production costs. One major challenge lies in material selection, as choosing the right material with the appropriate mechanical and thermal properties is critical for performance and durability. Mold design also plays a crucial role; any design flaws can lead to issues such as warping, sink marks, or incomplete filling of parts. Maintaining dimensional accuracy is another concern, as variations in temperature, pressure, or cooling can affect tolerances and consistency. Additionally, defects like flash, burn marks, or surface imperfections may occur if process parameters are not properly controlled.

Related Services

- CNC Machining: Precision machining of molds, inserts, and components to achieve tight tolerances and high-quality finishes.

- 3D Printing and Prototyping: Rapid prototyping to test part designs, functionality, and fit before full-scale molding production.

- Mold Design and Fabrication: Custom mold design and manufacturing to ensure accurate, efficient, and durable tooling.

- Product Design and Development: Conceptualization, 3D CAD modeling, and design optimization to create manufacturable and functional products.

- Reverse Engineering: Reproducing or improving existing components by creating digital models for new mold development.

Injection molding ensures seamless integration across every stage of product development and manufacturing. We offer CNC machining for creating complex geometries, intricate details, and high-precision components used in molds, prototypes, and production parts. Our 3D printing and prototyping services enable rapid design validation, functional testing, and iterative development, reducing production risks and accelerating time to market.

The Process

The injection molding process is a highly precise and controlled method for producing high-quality components.

- Design and Material Selection: Product design using 3D CAD software and material selection based on mechanical, thermal, and aesthetic requirements.

- Mold Design and Fabrication: Custom mold design and manufacturing using hardened steel or aluminum for durability and precision.

- Material Melting and Injection: Molten material is injected into the mold cavity under high pressure for accurate detailing.

- Cooling: Controlled cooling to solidify the material and ensure dimensional accuracy.

- Ejection: The finished part is ejected from the mold using ejector pins or plates.

- Trimming and Finishing: Excess material is removed, and surface finishing processes are applied as needed.

- Inspection and Quality Control: Rigorous inspection to verify dimensions, surface quality, and performance.

- Assembly and Packaging: Components are assembled, tested, and packaged for delivery, meeting customer specifications and industry standards.

This process ensures the production of high-quality components with precise dimensions and finishes, suitable for various industries and applications.

What are the applications of injection molding services across various industries?

- Automotive: Manufacturing components such as dashboards, bumpers, engine parts, clips, and interior trim with high precision and durability.

- Medical and Healthcare: Producing medical devices, surgical instruments, diagnostic equipment components, and laboratory tools with strict compliance to hygiene and safety standards.

- Consumer Electronics: Creating casings, connectors, buttons, and internal components for gadgets, home appliances, and wearable devices.

- Aerospace: Producing lightweight, high-strength components like air ducts, brackets, and housings that meet stringent industry specifications.

- Industrial Equipment: Manufacturing machine components, gears, valves, and specialized parts for industrial machinery and automation systems.

- Packaging: Producing containers, caps, closures, and custom packaging components for food, beverages, pharmaceuticals, and cosmetics.

- Consumer Goods: Creating toys, household items, sports equipment, and lifestyle products with consistent quality and finish.

- Electrical and Electronics: Fabricating insulators, switchgear parts, housings, and connectors that require high precision and heat resistance.

Why Choose RA Global?

RA Global Tech Solutions offers comprehensive injection molding services, catering to various industries with high-quality, precision parts. If you are looking for high-quality, effective injection molding services, RA Global Tech Solutions is the perfect choice for you. We have a team of experienced engineers and technicians who are dedicated to providing effective injection molding services. We have the expertise and resources to meet the needs of a wide range of customers, from small businesses to large corporations.

- Expertise: Skilled engineers and designers with industry-leading 3D CAD software expertise ensure high-quality deliverables.

- Advanced Technology: Utilization of cutting-edge software and equipment ensures accurate and efficient results.

- Customized Solutions: Tailored services meet specific client needs and requirements.

- Quality Assurance: Rigorous quality control processes guarantee precise and reliable outcomes.

- Innovative Approach: RA Global's team stays up-to-date with industry trends and best practices.

Do you have any project requirements where you are uncertain about which services are most suitable for your product? Kindly connect with us today to realize potential possibilities.

Frequently Asked Questions

What is injection molding?

It’s a manufacturing process where melted plastic is injected into a mold to produce high‑volume, consistent, and detailed plastic parts.

Why choose RA Global for injection molding?

We offer precision tooling, experienced engineers, material selection guidance, and quality control to deliver durable, accurate, and cost‑effective molded parts.

Which industries use injection molding?

Automotive, consumer goods, electronics, medical devices, and industrial equipment companies rely on it for the scalable production of plastic components.

Can you help with mold design?

Yes! Our team designs and optimizes molds to ensure efficient production, reduced cycle times, and high‑quality finished parts.

What materials can you mold?

We work with a variety of thermoplastics, including ABS, polypropylene, nylon, polycarbonate, and specialized engineering plastics for different applications.