Mould Manufacturing

What is mould manufacturing services?

Mould manufacturing services refer to the process of designing, engineering, and producing precision moulds or dies used in various manufacturing techniques such as casting, forging, injection molding, blow molding, and extrusion. These moulds are critical tools that shape raw materials into desired parts or components with accuracy and consistency.

Moulds can be made from high strength steel, aluminum, or other specialized alloys, depending on the application, production volume, and material being processed. They are essential for industries that require repeated production of identical parts, ensuring high-quality output, dimensional accuracy, and surface finish. Moulds are important for the production of a larger range of products, such as metals, food, and composites as well as plastics and polymer materials. Moulds are used to create duplicate objects of a desired object or shape by making a negative impression of it, which is surrounded with molten material.

The process of producing moulds is a little complicated and demanding of seamless accuracy and ability during the process. RA Global Tech Solutions is a leading provider of mould manufacturing services, with a team of professional engineers and technicians who can create moulds for different industrial and consumer parts.

Key Aspects of mould manufacturing services:

Mould manufacturing services play a critical role in ensuring precision, consistency, and efficiency in modern production processes. The key aspects include:

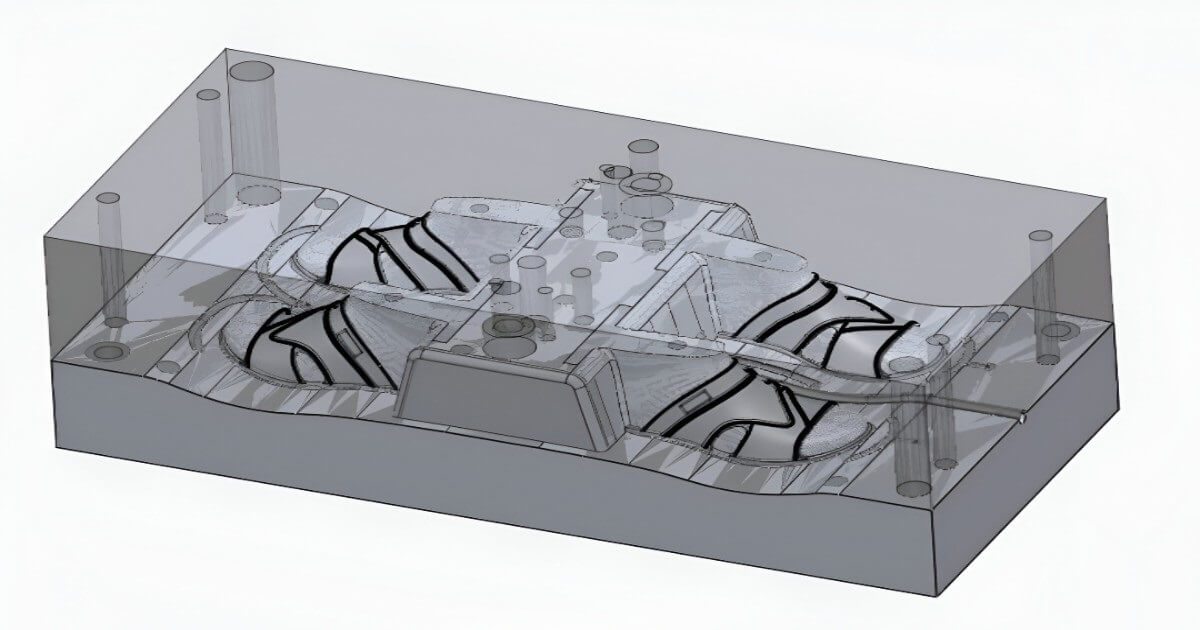

- Design and Engineering: Creating accurate 3D CAD models and technical drawings tailored to the product’s specifications, ensuring the mould will produce components with exact dimensions.

- Material Selection: Choosing appropriate materials such as tool steel, aluminum, or specialized alloys to ensure durability, wear resistance, and performance under production conditions.

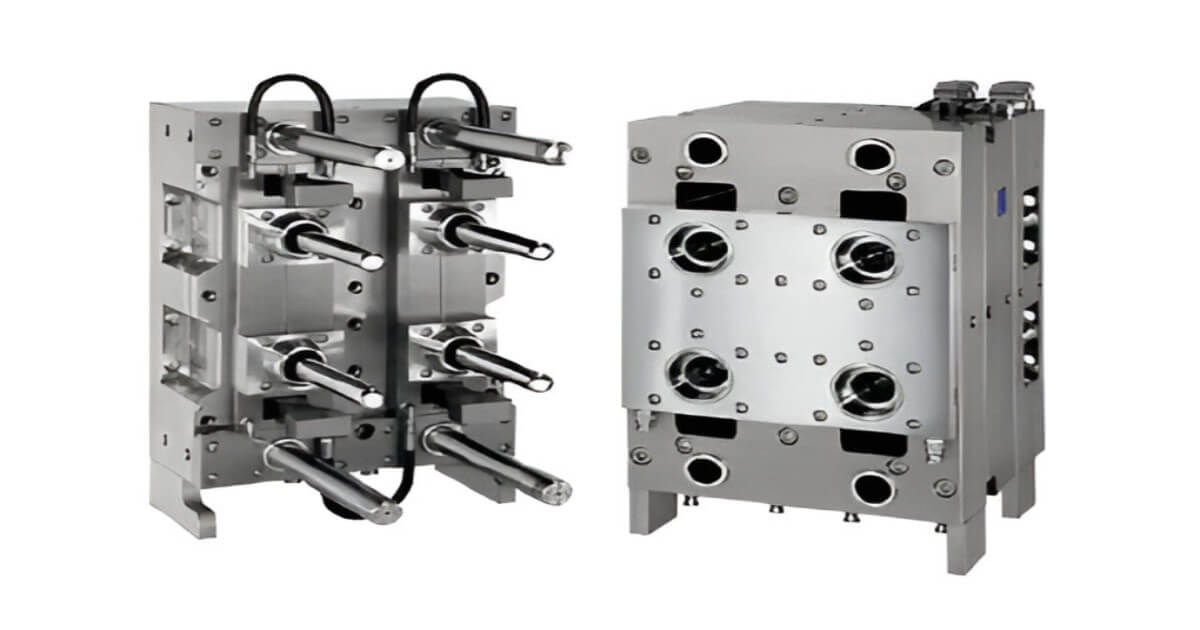

- Precision Machining: Utilizing advanced technologies like CNC milling, EDM (Electrical Discharge Machining), and grinding to achieve highly accurate mould components.

- Assembly and Trial Runs: Carefully assembling mould parts and conducting test runs to verify functionality, surface finish, and dimensional accuracy before mass production.

Why mould manufacturing services is important?

Mold manufacturing services are essential for various industries as they enable the production of high quality, precise, and complex parts. Molds facilitate efficient mass production of identical parts, reducing costs and increasing productivity while ensuring consistent quality and precise dimensions. This process allows for the creation of complex geometries that would be challenging or impossible to produce using other methods. By reusing molds multiple times, production costs are minimized, and waste is reduced. Mold manufacturing caters to diverse industries, including automotive, aerospace, medical, and consumer goods, driving innovation and reducing lead times for faster time to market.

What are the common challenges in mould manufacturing services?

Mould manufacturing services, while essential for producing precise and high-quality components, come with several challenges that manufacturers must address. Designing moulds for intricate and complex components requires highly skilled engineers and advanced 3D CAD modeling to avoid misalignments or defects. Selecting the right material is also critical to ensure durability, wear resistance, and heat tolerance, as using inappropriate materials can lead to premature mould failure. The initial design, prototyping, and manufacturing of moulds can be costly, especially for custom or complex designs, while achieving tight tolerances consistently across large production runs demands advanced machining techniques and meticulous quality control.

Related Services

We offer a comprehensive suite of services that support and enhance the mould manufacturing process:

- Design and Engineering Services: Creating precise 3D CAD models and technical drawings for moulds, ensuring accurate and efficient production.

- 3D Scanning and Reverse Engineering: Replicating existing components or creating digital models for complex mould designs.

- CNC Machining and EDM: High precision manufacturing of mould components using advanced CNC milling and electrical discharge machining techniques.

- Simulation and Optimization: Using computer-aided simulations to optimize mould performance, reduce defects, and improve efficiency.

- Surface Treatment and Finishing: Polishing, coating, or heat treating moulds to enhance durability, wear resistance, and performance.

- Prototyping and Testing: Conducting trial runs to ensure functionality, accuracy, and high-quality output before full-scale production.

- Maintenance and Refurbishment: Repairing, modifying, or upgrading moulds to extend lifespan and maintain consistent production quality.

The Process

We follow a systematic approach to ensure precision, durability, and high quality output in mould manufacturing:

- Requirement Analysis: Understanding client specifications, production volume, material requirements, and intended application of the mould.

- Design and 3D CAD Modeling: Creating detailed 3D models and technical drawings to ensure dimensional accuracy and manufacturability.

- Material Selection: Choosing the optimal material based on strength, wear resistance, and temperature tolerance.

- Prototype Development: Building prototypes or sample moulds for testing and validation before full-scale production.

- Precision Machining: Manufacturing mould components using CNC milling, EDM, grinding, and other advanced machining techniques.

- Assembly and Trial Runs: Assembling the mould and performing trial runs to check functionality, alignment, and surface finish.

- Surface Treatment and Finishing: Applying polishing, coating, or heat treatment to enhance durability and performance.

- Quality Inspection: Conducting CMM inspection, dimensional analysis, and functional tests to ensure the mould meets international standards.

- Maintenance and Support: Providing ongoing repair, refurbishment, and optimization services to extend mould life and maintain consistent production quality.

When designing a mould, several vital considerations must be taken into account, including part design, material selection, forbearance, and face finish. The mould design must take into account the part's figure, material, and product conditions. The mould material must be named rested on the product conditions, similar as temperature, pressure, and erosion resistance. The mould must be manufactured to precise forbearance to insure accurate product, and the face finish can affect the final products appearance and functionality. The benefits of mould manufacturing include high volume product of complex corridor with precise forbearance, cost effectiveness for large product runs, viscosity in product quality, and design harshness. Moulds insure harmonious product quality, reducing variability and scars, and can be designed to produce complex shapes and shapes. By using mould manufacturing, businesses can produce high quality products efficiently and effectively, while also reducing costs and perfecting product design.

What are the applications of mould manufacturing services across various industries?

Mould manufacturing services are widely used across multiple industries to produce high-precision, consistent, and complex components. Key applications include:

- Automotive Industry: Manufacturing engine components, transmission parts, body panels, and custom automotive parts requiring tight tolerances and durability

- Aerospace Industry: Producing turbine components, structural parts, brackets, and complex assemblies where precision and reliability are critical

- Consumer Goods: Creating plastic or metal components for household appliances, packaging, and everyday products.

- Medical Industry: Fabricating surgical instruments, medical devices, and implants that require high precision and strict quality standards

- Oil and Gas Industry: Producing valves, fittings, pump housings, and other components capable of withstanding high pressure and corrosive environments

- Industrial Machinery: Manufacturing gears, impellers, molds for casting, and other machinery parts with high strength and precision requirements

- Packaging Industry: Creating molds for plastic bottles, containers, and other packaging components for large scale production

- Defense and Military: Producing durable and precise components for weapons, vehicles, and defense equipment under extreme conditions

Why choose RA Global?

RA Global Tech Solutions stands out as a leader in mould manufacturing services due to its unwavering commitment to quality, innovation, and client satisfaction. We state of the art technology, customization options, and dedication to precision have positioned them as a go to choice for various industries. If you are looking for mould manufacturing services that combine expertise, innovation, and cost effectiveness, RA Global should undoubtedly be at the top of your list.

- With over 7 years of professional experience in the industry, we have successfully collaborated with a wide range of clients, with unique requirements from them.

- Our skilled engineers and designers are well-versed in all aspects of mould manufacturing, ensuring that every project is executed with precision.

- From Concept Design to delivery, RA Global Tech Solutions provides end to end solutions, simplifying the entire process for clients.

- RA Global reach extends beyond regional boundaries, serving clients globally and establishing itself as a trusted partner on an international scale.

For more information about our top notch mould manufacturing services and to explore our portfolio, please Get In Touch with us.

Frequently Asked Questions

What is mould manufacturing?

It is the process of designing and producing precision molds used to shape plastic, metal, or composite parts through injection, casting, or forming.

Why choose RA Global for mould manufacturing?

We combine skilled engineering, advanced CNC machining, quality materials, and strict quality control to deliver durable, accurate, and production-ready molds.

Which industries need moulds?

Automotive, consumer products, electronics, medical devices, and industrial equipment manufacturers use molds for mass production of complex, high‑quality components.

Can you help with mold design and optimization?

Yes! Our team designs and refines molds to improve cycle times, part quality, and cost‑effectiveness during production.

What types of molds do you produce?

We produce injection molds, die‑casting molds, blow molds, and other custom tooling tailored to your product design and material requirements.