Metal 3D printing, also referred to as metal additive manufacturing, has emerged as a disruptive manufacturing technology enabling the production of complex, high-performance metal components. Using processes such as Selective Laser Melting, Direct Metal Laser Sintering, Electron Beam Melting, and Binder Jetting, metal 3D printing enables layer-by-layer fabrication of parts directly from 3D CAD data. Unlike conventional subtractive manufacturing, metal 3D printing offers design freedom, topology optimization, part consolidation, lightweighting, and rapid production, making it suitable for high-value industrial applications.

Let's explore how metal 3D printing is transforming these sectors.

Metal 3D printing enables the aerospace and defense sector to produce lightweight, high-performance components with optimized designs that improve fuel efficiency and increase payload capacity, while also allowing the creation of complex geometries such as turbine blades, fuel nozzles, and heat exchangers that enhance performance and reliability. The technology supports rapid prototyping, enabling faster design iterations and significantly shorter development cycles, which is critical for mission-driven programs. It is also cost-effective, as it reduces material waste, tooling requirements, and lead times, especially for low-volume, high-value parts. On-demand production minimizes downtime and enables quick repairs, even in remote or critical operational environments.

Additionally, metal 3D printing supports the use of aerospace-grade materials like titanium, aluminum alloy, and stainless steel alloy to withstand extreme conditions, contributes to advance manufacturing technology through intricate geometries that reduce natural resources, and promotes sustainability by lowering material waste, energy consumption, and transportation needs.

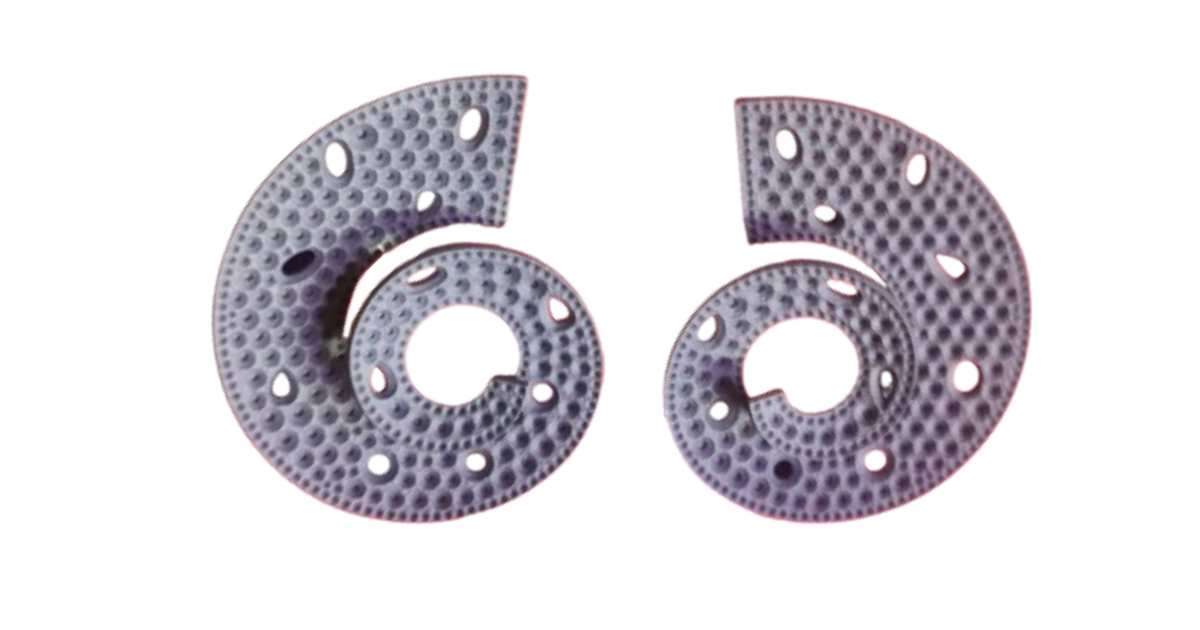

Automotive engineering focuses on performance, efficiency, and design flexibility areas where metal 3D printing delivers strong advantages. Initially adopted by premium and supercar manufacturers, the technology is now steadily moving into mainstream automotive production. It enables the creation of custom and low-volume components such as high-end engine parts, bespoke suspension systems, and prototype tooling, making it ideal for specialized applications. Metal 3D printing supports lightweighting by reducing mass in drivetrain and structural components, directly improving fuel efficiency and vehicle performance. It is also widely used for producing custom tooling, jigs, and fixtures that enhance production speed, accuracy, and overall quality. Rapid prototyping and testing allow designers to iterate designs quickly without the delays and costs associated with traditional molds or dies.

Additionally, part consolidation is becoming increasingly common, where multiple components are combined into a single 3D-printed part, reducing assembly time, lowering failure points, and improving overall system reliability.

Metal 3D printing is increasingly being used not only for functional benefits but also for aesthetic and personalization advantages. Manufacturers leverage the technology to produce customized metal braces, connectors, and structural components for wearables and electronics, enabling compact, durable, and precisely fitted designs. High-end consumer products such as luxury watches, jewelry, and bespoke accessories benefit from the intricate surface textures, fine details, and complex geometries that metal additive manufacturing can achieve.

In sporting goods, metal 3D printing supports the production of lightweight yet strong components for bicycles, golf clubs, and other high-performance equipment, improving durability and user performance. A key advantage for consumer brands is the ability to offer personalization, where functional custom parts tailored to individual user measurements enhance product value, differentiation, and overall customer experience.

Drones aerial vehicles, are rapidly expanding across recreational, commercial, and military applications, and metal 3D printing is well suited to meet the demanding design requirements of this evolving field. The technology enables significant weight reduction while maintaining high strength, allowing lightweight metal components to extend flight time without compromising durability. Metal 3D printing also supports complex, topology-optimized geometries for custom frames, motor mounts, and propulsion systems that improve aerodynamic efficiency and structural performance. Rapid iteration is another key advantage, as developers can quickly test and refine new airframe designs without the long lead times associated with traditional machining or casting.

In addition, multiple components can be integrated into a single 3D printed part, simplifying assembly, reducing failure points, and improving overall reliability. For advanced drones used in defense, surveillance, or industrial inspection where performance is critical metal 3D printing offers designers unmatched flexibility and innovation potential.

The push toward electrification has reshaped vehicle design priorities: efficiency, thermal management, lightweight structures, and integration of electronic components.

Metal 3D printing supports these trends in remarkable ways.

As EV production scales up, metal AM offers flexibility when production must adapt to market demand or new design requirements.

Metal 3D printing has progressed from a rapid prototyping tool to a full-scale production enabler, supporting flexible, digital, and demand-driven manufacturing. Unlike traditional methods that depend on complex tooling, long setup times, and high minimum order quantities, metal additive manufacturing allows manufacturers to produce parts directly from 3D CAD data using technologies such as Selective Laser Melting, Direct Metal Laser Sintering, and Binder Jetting. This capability significantly reduces lead times and improves operational agility. Metal 3D printing enables rapid tooling by producing jigs, fixtures, and molds faster to streamline assembly and CNC machining, while also making short-run production economically viable without the burden of high tooling costs.

It supports the quick delivery of customized components for machinery and research equipment and allows spare parts to be produced on demand, eliminating the need for large inventories and warehousing. Overall, metal 3D printing enhances responsiveness, shortens lead times, and provides a strategic advantage in markets with fluctuating demand.

The healthcare and medical device sector is one of the most transformative areas for metal 3D printing, where precision, biocompatibility, and patient-specific customization are essential. Traditional manufacturing often struggles to produce anatomically complex, customized components within short lead times, whereas metal 3D printing enables highly accurate, patient-matched solutions. In orthopedics, implants such as hip joints, knee replacements, and spinal implants can be tailored to a patient’s anatomy, improving comfort, fit, and long-term clinical outcomes.

Dental applications benefit from metal 3D printing’s micron-level accuracy and excellent surface finish, making it ideal for producing dental implants, crowns, and small, complex components with high repeatability. The technology also supports the production of customized surgical tools that meet strict requirements for mechanical strength, sterilization, ergonomics, and dimensional accuracy, allowing instruments to be optimized for specific procedures or surgeon preferences.

In prosthetics, metal 3D printing enables the creation of lightweight, high-strength, fatigue-resistant components that are custom-fitted to individual users, enhancing comfort and functionality. Overall, metal 3D printing’s ability to deliver patient-specific solutions allows surgeons to order implants precisely matched to a patient’s anatomy, reducing recovery times, improving performance, and achieving outcomes that traditional mass manufacturing cannot match.

Metal 3D printing plays a key role in advancing performance, speed, and design flexibility as robots become central to manufacturing, logistics, and service industries. The technology enables the production of lightweight yet high-strength components that are essential for fast, precise robotic arms, allowing rapid movement with minimal inertia and improved energy efficiency. Metal 3D printing also supports the creation of complex joints and actuators with customized geometries, providing greater degrees of freedom and enhanced motion control.

End-effectors and tooling such as grippers, sensor housings, and application-specific attachments can be optimized for individual tasks, improving accuracy and functionality. In addition, rapid prototyping and production allow engineers to iterate robotic designs quickly, significantly reducing development cycles and time to deployment. Overall, metal 3D printing enhances the capability, adaptability, and performance of robotic systems across both industrial automation and service-oriented applications.

Across aerospace, automotive, healthcare, energy, robotics, consumer products, and general manufacturing, RA Global Tech Solutions stands out as a trusted partner for metal 3D printing by aligning advanced technology with real-world engineering needs. RA Global Tech Solutions enables true design freedom, allowing desginer to move beyond the constraints of traditional milling, casting, or forging and realize complex internal channels, lattice structures, and organically optimized geometries that unlock higher performance. Through part consolidation, RA Global Tech Solutions reduces multiple assemblies into single, robust 3D printed components, cutting assembly time, lowering failure points, and improving reliability.

RA Global’s Tech Solutions capabilities also deliver speed and flexibility, supporting rapid prototyping to shorten development cycles and on-demand production to reduce inventory and logistics costs. The ability to economically support customization from patient-specific medical implants to bespoke consumer and industrial components adds significant value across industries. While metal 3D printing may have a higher per-unit material cost, we at RA Global Tech Solutions helps customers achieve overall cost efficiency by minimizing tooling, reducing assembly complexity, and lowering inventory requirements, making metal 3D printing an increasingly smart choice for complex, low-to-medium volume production.

Metal 3D printing is no longer an experimental technology it is a driving force behind industrial innovation. From cutting-edge aerospace components and custom medical implants to advanced robotics and consumer product design, metal additive manufacturing is reshaping the way we create and think about manufacturing.

Across industries, it empowers engineers to design beyond the constraints of traditional processes, optimize performance, and respond fast to changing market demands. As technology continues to mature and costs decline, metal 3D printing will only become more widespread transforming the future of engineering and industry at large.

© 2026 RA Global Tech Solutions

Site design and developed by Rajkar Global