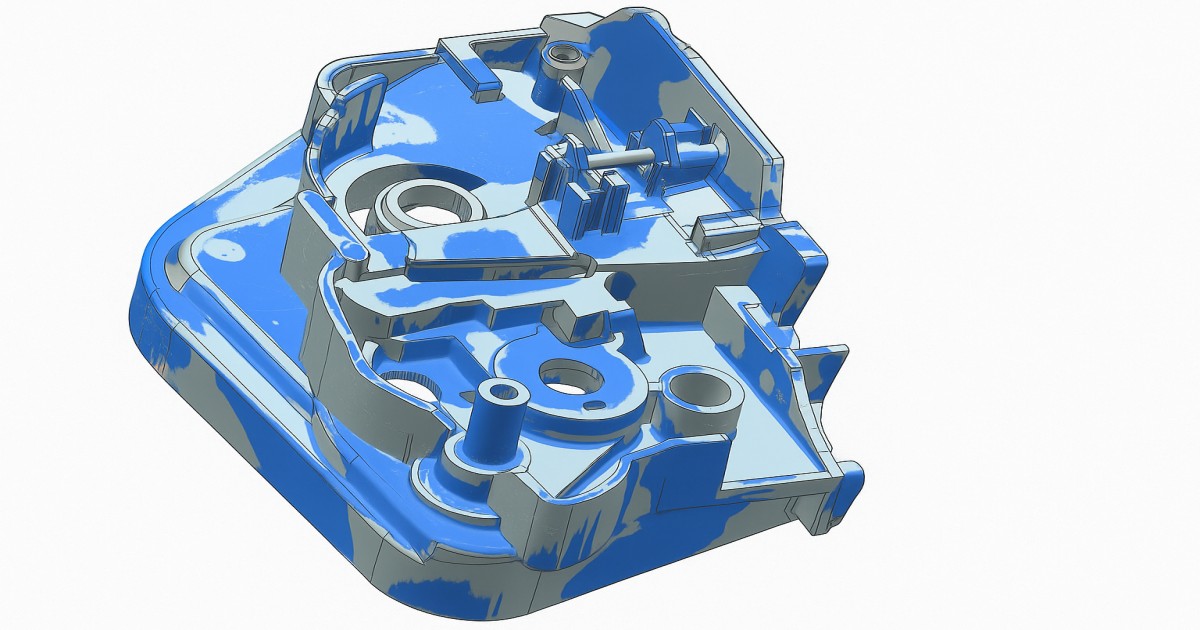

3D scanning and reverse engineering are processes that essentially go hand in hand. 3D scanning technology is used to quickly measure intricate objects, producing a digital 3D scan of the object. This is essentially done by reflecting a light or laser onto the surface of the object, where the pattern and surface of the object cause an interference. The cameras installed in the device capture the changes in data, compiling it to produce a digital 3D copy of the object.

3D reverse engineering is made possible due to 3D scanning, as the digital copy retrieved is then used to remanufacture the object without the need for the original physical drawings or plans. The combination of these technologies aids several industries in their design process, producing faster results and reducing costs.

The automobile sector benefits greatly from this technology. Old/antique cars often stop running on the road, as they have parts that don’t work anymore. It is often challenging to find a replacement for their parts, as manufacturing for them has been stopped for a long time. Furthermore, there are often no prints or designs available, making it much more difficult to remake the part. With the help of 3D scanning, the process to redesign the non-working part becomes very easy and can be reverse engineered.

In recent years, customized Formula 1 car manufacturers have used this technology, as manufacturers are often unwilling to reveal their engine design. Therefore, to understand the dimensions and exterior of the vehicle and engine better, race car manufacturers utilize 3D scanning and 3D reverse engineering to design their customized cars more efficiently.

This technology is gaining rapid popularity in the health industry as well. Doctors are able to reduce surgery times by utilizing this technology, as they are able to reverse engineer customized bones of individuals at a faster speed along with 3D printing. Museums are also using this technology to their advantage by making copies of fragile artifacts and using these copies to be displayed. Their replica designs are more accurate representations of the actual artifact when made through using 3D scanning, 3D reverse engineering, and 3D printing than they would be through any other method.

In the past few years, the development in this area of technology has allowed the prices of 3D scanning equipment to go down by several folds. This drop in prices enables individual designers and engineers, as well as smaller firms, to employ this technology and allows creativity and efficiency to rise. This process has also reduced the product design cycle, making the designing process much smaller and speedier, saving time and money.

However, copyright challenges still haunt original designers of products, as with the wide availability of this 3D scanning technology, the chances of their product idea being stolen will increase. Institutes need to update their outdated copyright laws to keep up with the technology in order to safeguard the interests of designers.

The introduction of artificial intelligence to make it easier for public use and the making of a smaller device that could be carried around everywhere are definitely going to be beneficial in the long run.

© 2026 RA Global Tech Solutions

Site design and developed by Rajkar Global