FDM 3D Printing: Fused Deposition Modeling

What is FDM 3D printing?

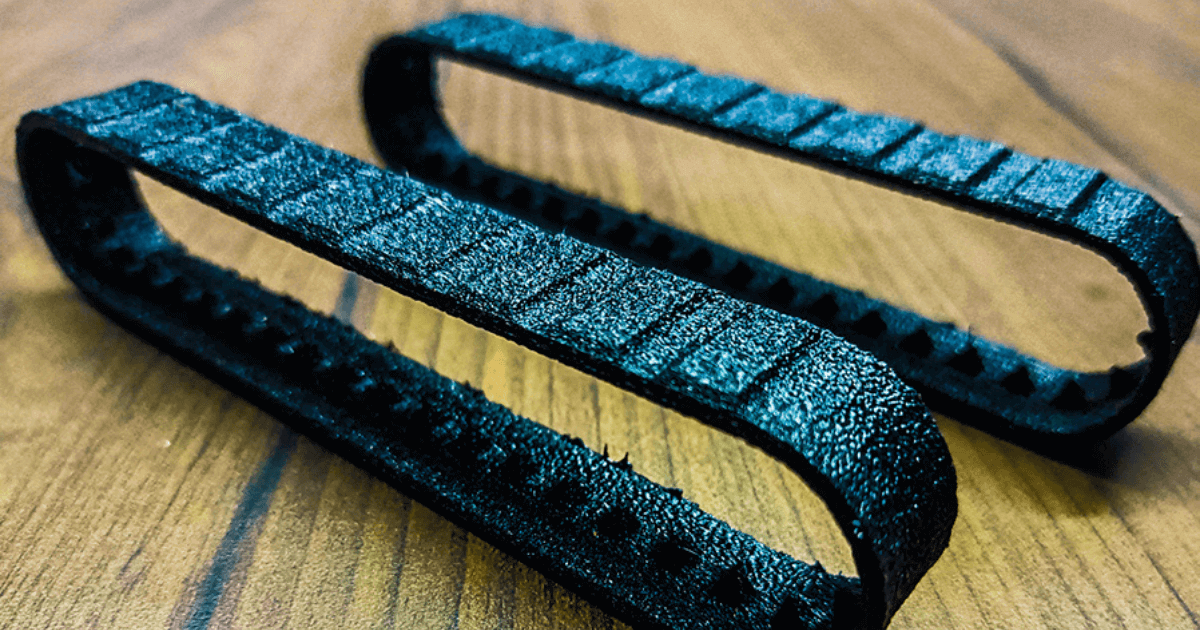

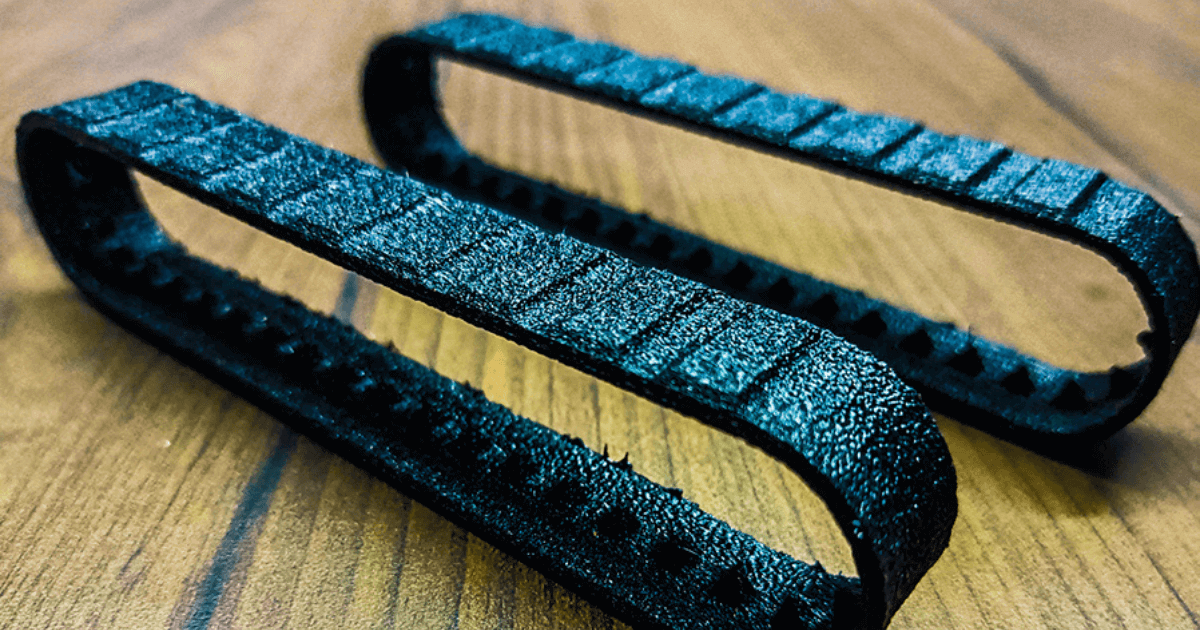

FDM 3D printing is a type of additive manufacturing that creates objects layer by layer, using melted plastic filament. The process involves extruding thermoplastic material through a heated nozzle, which is then deposited onto a build platform, solidifying as it cools. This layer-by-layer approach allows for complex geometries and intricate designs, making FDM 3D printing an ideal solution for rapid prototyping, product development, and production.

At RA Global Tech Solutions, we are at the forefront of innovation, leveraging cutting-edge technologies to transform industries. One such technology that's making waves is Fused Deposition Modeling (FDM) 3D printing. In this article, we will delve into the world of FDM 3D printing, exploring its benefits, applications, and how it's revolutionizing manufacturing.

Key Aspects of FDM 3D printing

- Layer-by-Layer Manufacturing: FDM 3D printing builds objects by extruding melted thermoplastic filament, depositing it layer by layer to form accurate and durable structures.

- Wide Material Compatibility: Supports a variety of thermoplastic materials such as PLA, ABS, PETG, TPU, nylon, and composite filaments, allowing flexibility in strength, durability, and application.

- Strong and Functional Parts: Produces robust and practical components suitable for both prototype validation and end-use applications.

- Design Freedom: Capable of creating complex geometries, intricate internal structures, and custom shapes that are difficult or impossible with traditional manufacturing.

- Fast Turnaround Time: Quick setup and printing cycles enable faster product development, iteration, and time-to-market.

How does FDM 3D printing work?

In FDM 3D printing, the process begins by loading a thermoplastic filament into the printer. The nozzle is then heated to the required temperature, allowing the filament to feed into the extrusion head and melt. Guided by a three-axis system (X, Y, and Z), the nozzle extrudes the molten material into thin strands, which are deposited layer by layer according to the digital 3D model. In many cases, cooling fans near the nozzle help accelerate solidification for better print stability.

A single pass cannot fill an entire section, so the nozzle makes multiple passes to gradually build the structure. After each pass, it returns to its starting position to begin the next layer. This repetitive layering continues until the complete part is formed. Cooling mechanisms are activated between layers to prevent deformation and maintain dimensional accuracy. Because of its precision, reliability, and ease of use, FDM remains one of the most advanced yet user-friendly 3D printing technologies available today.

Types of Materials Used in FDM 3D printing

- ABS-Acrylonitrile Butadiene Styrene: Decent strength, Good resilience to temperature, Less resistant to warping

- PLA-Polylactic acid: Outstanding visual quality, Low impact strength, Simple to print

- PETG-Polyethylene terephthalate glycol: Food safe, Decent strength, Easily printable

- TPU-Thermoplastic Polyurethane: Very flexible, Difficult to print accurately

- Nylon (PA)-Polyamide: High strength, excellent wear, and chemical resistance

- Industrial Grade: PA12-CF Filament, PPS-CF, UltraPA-CF25 (PPS-CF core), PAHT-GF, PET-GF, PET-CF, PAHT-CF (PPA-CF), PA12-CF, Ultra PA Nylon, PC/ABS-FR

- High Performance: TPU-Aero, ABS-GF25, PLA-CF, PETG-Tough, S-White, ASA, TPU95A-HF, ASA-Aero

FDM 3D printing Capabilities

- Maximum Build Size: 500 x 500 x 500 mm

- Standard Lead Time: 2 Business Days

- Dimensional Accuracy: ± 0.5% with a lower limit of ± 0.5 mm

- Layer Height: 100-300 μm

- Infill: 20-100%

Design Guidelines for FDM 3D printing

- Unsupported walls: 0.8 mm

- Supported walls: 0.8 mm

- Minimum feature size: 2.0 mm

- Minimum hole diameter: 2.0 mm

Benefits of FDM 3D printing

- Cost-Effective: FDM 3D printing reduces material waste and minimizes labor costs, making it an economical solution for small-batch production and prototyping.

- Increased Design Complexity: FDM 3D printing enables the creation of complex geometries and internal structures, impossible to achieve with traditional manufacturing methods.

- Rapid Prototyping: FDM 3D printing accelerates the product development process, allowing for quick design iteration and testing.

- Material Versatility: FDM 3D printing supports a wide range of thermoplastic materials, each with unique properties and applications.

Applications of FDM 3D printing

- Aerospace: In simple terms, aerospace research heavily depends on FDM 3D printing. Many of the components used in this industry are highly complex and cannot be produced manually or with conventional manufacturing techniques. As a result, FDM has become a crucial technology for aerospace development. From small precision components to large, industrial-grade parts used in advanced machinery, FDM plays an essential role in enabling efficient, accurate, and innovative production.

- Automotive: As automotive technology evolves, vehicles now incorporate numerous advanced features designed to make travel safer and more convenient. Many of these innovations rely on highly precise and intricately engineered components, which can be challenging to produce using traditional methods. FDM 3D printing offers a significant advantage in this area, enabling manufacturers to create complex parts with ease and accuracy. With just a single digital 3D model, companies can produce these components in bulk, streamlining production and ensuring consistent quality.

- Dental and Medical: The dental healthcare sector is one of the leading adopters of FDM 3D printing, utilizing the technology to its fullest potential. In dentistry, professionals commonly use FDM to create accurate prototypes and treatment models. One of its key advantages is that FDM materials can meet medical-grade standards, enabling doctors to perform complex procedures with confidence and deliver high levels of patient satisfaction. Beyond dental implants, FDM 3D printing is also used to produce a variety of other medical and anatomical implants, further expanding its role in modern healthcare.

- Jewelry: Jewelry is an essential accessory that enhances a person's overall appearance, and crafting intricate pieces requires precision and attention to detail. With FDM 3D printing, designers can create finely detailed components and achieve virtually unlimited customization based on customer preferences. This technology enables the production of unique, complex jewelry designs while ensuring high-quality finishes and visually striking final products.

- Art and Sculpture: Art has no boundaries when it comes to innovation, and FDM 3D printing has opened new possibilities that were once considered impossible. The integration of FDM technology has transformed the world of sculpture and artistic creation, enabling artists to produce complex and dynamic designs with remarkable ease. Today, many organizations rely on FDM for large-scale production of artwork, benefiting from its precision, flexibility, and creative freedom.

At RA Global, we are harnessing the power of FDM 3D printing to drive innovation and efficiency in various industries. Our team of experts works closely with clients to design and develop customized solutions, leveraging the benefits of FDM 3D printing to reduce costs, increase productivity, and improve product quality. FDM 3D printing is transforming the manufacturing landscape, offering unparalleled design flexibility, cost-effectiveness, and speed. At RA Global, we are committed to staying at the forefront of this technology, delivering innovative solutions that drive business growth and success. Whether you are looking to prototype, produce, or innovate, our team is here to help you harness the power of FDM 3D printing.

We manufacture your parts according to strict manufacturing standards. Verification of these requirements is included in our inspection report that is shipped with every order.

UPLOAD your design for an Instant Quote (Acceptable file types are .stl, .step, and .x_T.)

Frequently Asked Questions

What is FDM 3D printing?

FDM (Fused Deposition Modeling) is an additive process where a heated nozzle deposits melted plastic filament onto a platform, building the part up layer by layer. It is the most common and accessible form of 3D printing.

What materials does FDM primarily use?

FDM primarily uses various thermoplastic filaments like PLA, ABS, PETG, nylon, and TPU. Specialty filaments reinforced with carbon fiber or glass fiber are also available for stronger, more rigid applications.

What are the key advantages of FDM?

Its primary benefits are cost-effectiveness, speed for rapid prototyping, and a vast selection of durable and functional materials. It is an excellent choice for large-format and mechanical parts.

What are the main limitations of FDM prints?

FDM parts typically have visible layer lines and lower resolution compared to resin printing (SLA). The bond between layers can result in weaker parts, especially along the Z-axis.

What is FDM used for in industries?

FDM is used extensively for rapid prototyping, creating custom tooling (jigs and fixtures), and producing durable end-use components in automotive, aerospace, and engineering fields.