Metal 3D Printing

What is a metal 3D printing service?

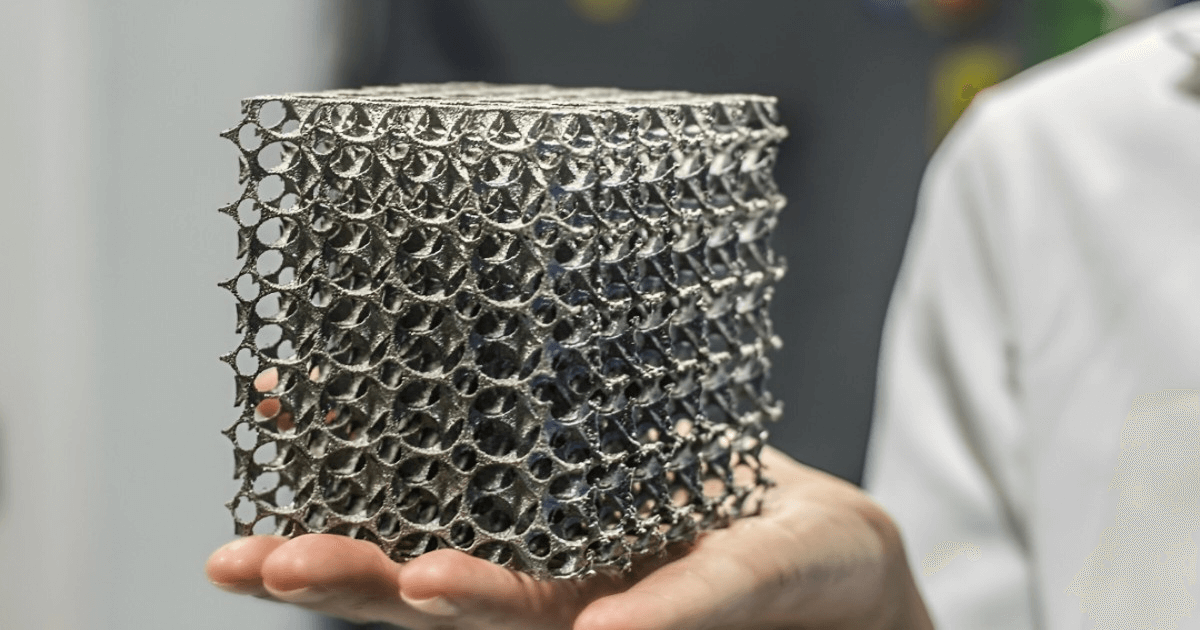

Metal 3D printing service is a type of additive manufacturing that creates complex metal parts and products layer by layer. This technology allows for the production of intricate geometries, complex structures, and customized designs that cannot be produced through traditional manufacturing methods. Metal 3D printing is a revolutionary manufacturing process that constructs complex metal parts layer by layer, directly from digital designs. This additive approach enables the creation of intricate geometries and customized structures that traditional methods cannot match.

At RA Global, we are dedicated to harnessing the transformative power of metal additive manufacturing to push the boundaries of innovation and excellence. By leveraging advanced metal 3D printing technologies, we are enabling the creation of complex, high-performance parts and products that are redefining industries and transforming the future of manufacturing.

Key Aspects of metal 3D printing service:

- Additive Manufacturing: Parts are built layer by layer, allowing precise control over geometry and material placement.

- Complex Geometries: Enables the creation of intricate designs and internal structures that are difficult or impossible with traditional methods.

- Material Variety: Supports a wide range of metals, including aluminum, titanium, stainless steel, and specialty alloys, tailored to application requirements.

- Precision: Delivers high dimensional accuracy and superior surface finish for functional and end-use parts.

- Customization: Produces tailored components to meet specific design, performance, and functional needs.

- Rapid Prototyping: Facilitates quick production of prototypes for testing, validation, and iterative design.

- Industry Applications: Widely used across aerospace, automotive, medical, industrial, and defense sectors.

These aspects make metal 3D printing a powerful technology for innovation, efficiency, and performance in modern manufacturing.

Why is metal 3D printing service important?

Metal 3D printing is revolutionizing modern manufacturing by enabling innovative, efficient, and high-precision production. It allows the creation of complex geometries, intricate internal structures, and optimized lightweight components that are difficult or impossible to achieve with traditional manufacturing methods. This technology supports rapid prototyping and product development, reducing design cycles and accelerating time-to-market. By building parts layer by layer, metal 3D printing minimizes material waste, resulting in cost-effective and sustainable production. It delivers high precision and consistent quality, meeting stringent tolerances and surface finish requirements.

Additionally, it enables customized and low-volume production for specialized components in industries such as aerospace, automotive, medical, defense, and industrial equipment. With the ability to produce functional, lightweight, and optimized parts, metal 3D printing has become a critical tool for innovation, efficiency, and performance across multiple sectors.

What are the common challenges in metal 3D printing services?

Metal 3D printing services face several challenges, including high costs associated with equipment and materials and a limited range of printable metals, which can restrict certain applications. Ensuring consistent part quality is another critical concern, as the printing process can introduce variability in dimensions, density, and mechanical properties. Additional complexities include post-processing requirements to achieve the desired surface finish, design optimization for printability, and the management of residual stress and potential distortion caused by rapid heating and cooling. Moreover, adhering to industry-specific certifications and standards can be demanding, requiring specialized expertise, careful planning, and rigorous quality control to produce reliable, high-performance components.

Related Services

RA Global Tech Solutions offers a suite of complementary services that enhance metal 3D printing capabilities and provide end-to-end solutions for clients:

- CNC Machining: Precision machining of 3D printed or custom metal parts to achieve tight tolerances and superior surface finishes

- Sheet Metal Fabrication: Laser cutting, bending, and welding to produce custom metal components for hybrid manufacturing needs

- Reverse Engineering: Converting existing parts into digital CAD models for reproduction, modification, or enhancement using metal 3D printing

- CAD Design and 3D Modeling: Creating highly accurate digital models optimized for additive manufacturing, including simulations for printability and performance

- Prototyping Services: Rapid production of functional prototypes to test fit, design, and functionality before full-scale manufacturing

- Product Design and Engineering Optimization: Part design, structural analysis, and testing to ensure components are manufacturable, efficient, and cost-effective

The Process

Metal 3D printing works by first creating a 3D CAD model of the desired part. This model is then sliced into several layers by slicing software, and then this data is transferred to the metal 3D printer. A high-powered laser then melts the powdered metal on the build platform in the desired pattern, creating a solid metal.

- Design: A 3D CAD (Computer-Aided Design) file is created, defining the part's geometry and structure.

- Powder Preparation: A metal powder is prepared, consisting of fine particles with specific properties.

- Layer Formation: A thin layer of powder is spread evenly over the build platform.

- Laser Sintering: A high-powered laser selectively fuses the powder particles, tracing the part's geometry.

- Layer Buildup: The build platform lowers, and a new layer of powder is spread. The laser sinters the next layer, bonding it to the previous one.

- Repeat: Steps 4 and 5 are repeated, gradually building the part layer by layer.

- Post Processing: The finished part is removed from the build platform, and any support structures are removed. Additional processing, such as machining or surface finishing, may be applied.

What are the applications of metal 3D printing services across various industries?

- Aerospace: Manufacturing engine components, brackets, turbine blades, and lightweight structural parts that require high strength-to-weight ratios.

- Automotive: Producing custom performance parts, engine components, prototypes, and tooling with precise tolerances.

- Medical and Healthcare: Creating custom implants, prosthetics, surgical instruments, and dental components that are patient-specific and biocompatible.

- Defense and Military: Fabricating specialized equipment, armor components, and complex mechanical parts with stringent durability requirements.

- Industrial Equipment and Tooling: Producing machinery components, molds, jigs, and fixtures that demand precision and robustness.

- Energy and Power: Manufacturing components for oil and gas equipment, renewable energy systems, and nuclear power plants with high-performance material properties.

- Consumer Products: Producing customized goods, appliances, sports equipment, and musical instruments with intricate designs.

- Prototyping and Product Development: Rapidly developing functional prototypes to test design, functionality, and performance before full-scale production

Why Choose RA Global?

At RA Global, we are committed to delivering high-quality metal 3D printing services that meet your specific needs. Here are just a few reasons why you should choose us:

- Expertise: Our team of experienced engineers and technicians ensures high-quality parts and exceptional customer service. We work closely with you to understand your requirements and deliver parts that meet your exact specifications.

- State-of-the-Art Technology: We invest in the latest metal 3D printing technologies to ensure precision and accuracy. Our machines are regularly maintained and updated to ensure optimal performance.

- Quality Control: We follow strict quality control processes to guarantee your parts meet the required specifications. Our team of experienced engineers and technicians inspects every part to ensure it meets our high standards.

- Flexibility: We offer flexible production options, including small batches and one-off parts, to meet your specific needs. Our team works closely with you to understand your requirements and deliver parts that meet your exact specifications.

Contact us today to learn more about our metal 3D printing services. We would be happy to answer any questions you have and help you get started with metal 3D printing.

Frequently Asked Questions

What is metal 3D printing?

Metal 3D printing, also known as additive manufacturing, is a process of creating complex metal parts layer by layer using a 3D model.

How does metal 3D printing work?

Metal 3D printing works by fusing together metal powders or wires using a laser, electron beam, or other energy source, layer by layer, to create a complex metal part.

What are the benefits of metal 3D printing?

The benefits of metal 3D printing include increased complexity, improved performance, reduced lead time, and cost-effectiveness.

Can I use existing CAD designs for metal 3D printing?

Yes, but designs may need to be optimized for metal 3D printing.

Is metal 3D printing sustainable?

Yes, metal 3D printing can be sustainable by reducing material waste and energy consumption.